Form I-RA/D 350/500, P/N 131090R12, Page 31

Maintenance

Procedures

Continued

Removing Burner

and Cleaning End

Cone, Nozzle,

and Electrodes

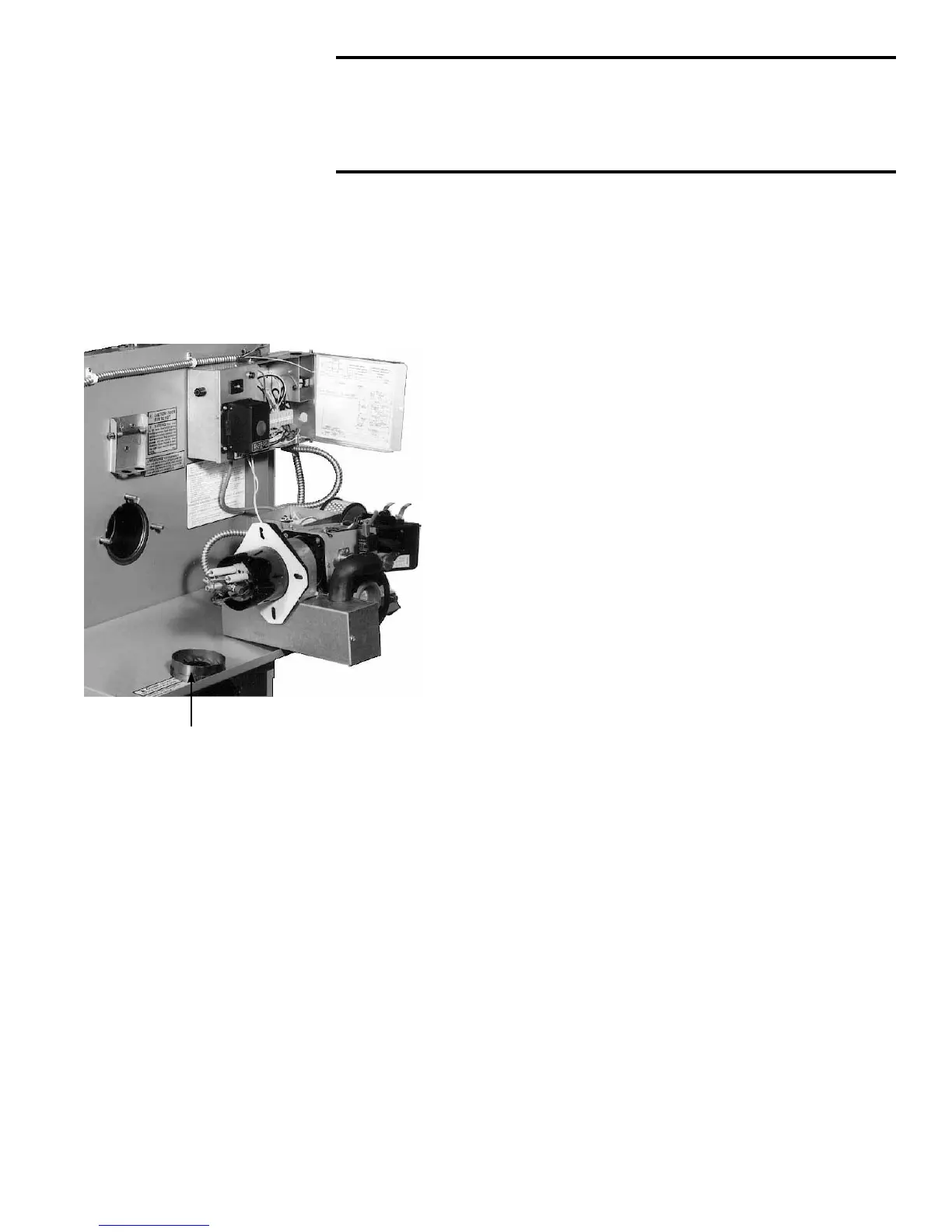

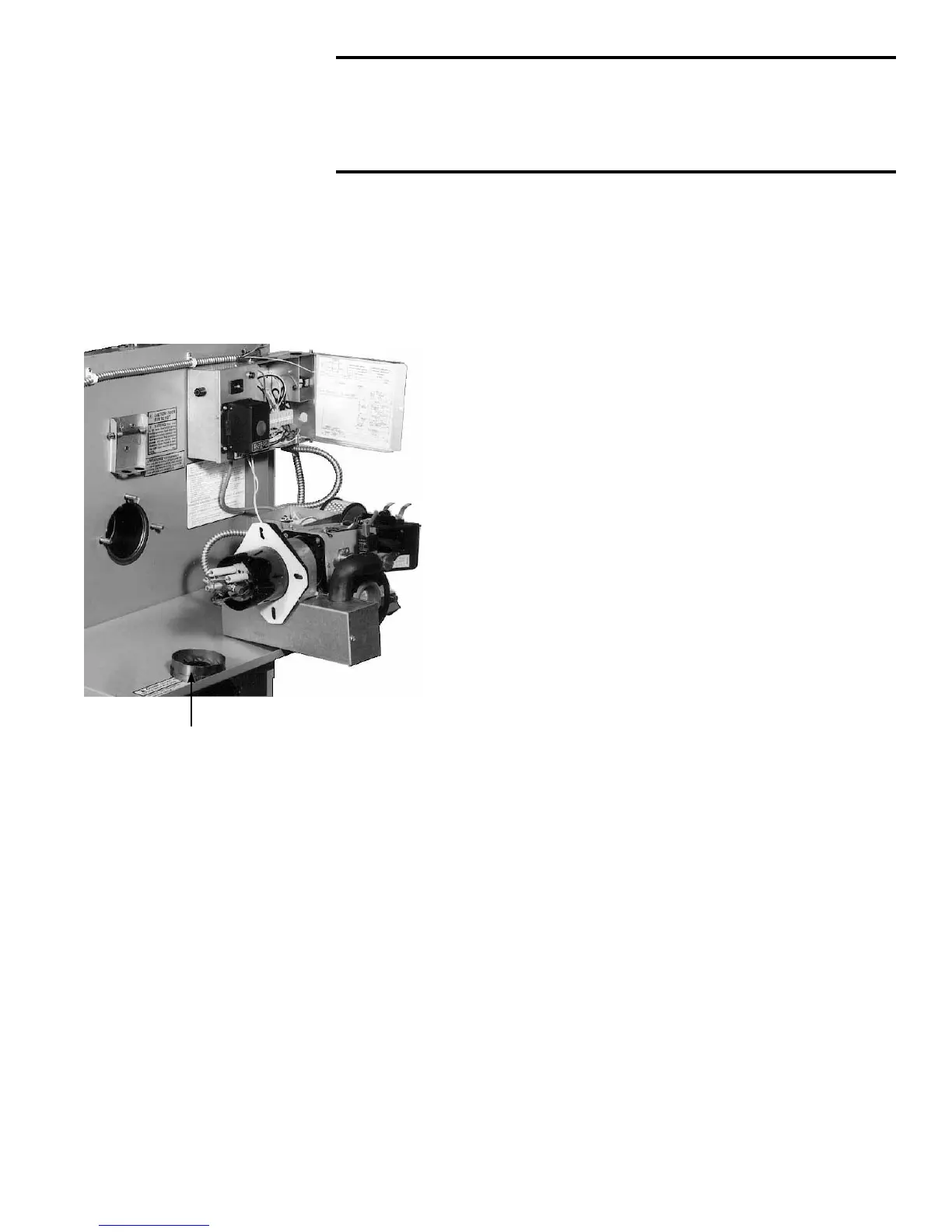

End Cone

Removed

WARNING: Turn off the electric power before burner

is removed for service.

To gain access to the end cone, the burner must be

removed.

1. To Remove Burner

• Locate the two yellow wires that go from the burner to the ignition

controller.

• Disconnect these wires at the terminals on the ignition controller.

• Remove the three nuts and washers that retain the burner to the

heater.

• Slide the burner off the bolts and rotate as illustrated.

2. To Remove/Clean the End Cone

• Remove the screws that hold the end cone to the

burner tube.

• Remove and clean the end cone using a stiff wire

brush.

• Check the end cone for deterioration and replace if

deterioration exists.

3. To Remove the Nozzle (requires both a 1” and a 5/8”

open-end wrench)

• To prevent the fuel line assembly from twisting, use a

1” open-end wrench to hold the nozzle adapter while

removing the nozzle with a 5/8” open-end wrench.

• Clean nozzle by disassembling, washing thoroughly,

and blowing dry with compressed air.

• If nozzle face appears worn, replace the oil nozzle.

For Models RA/RAD350, use replacement oil nozzle

P/N 129382; for Models RA/RAD500, use replacement oil nozzle

P/N 157041. Annual nozzle replacement is recommended. This

nozzle is custom designed. Do not substitute nozzle.

• Replace the end cone.

NOTE: Be sure NOT to damage the “O” ring on the nozzle. If the

“O” ring appears damaged, replace the nozzle.

4. Inspect the Electrodes

• The electrode porcelain insulators must be free from carbon,

oil, dirt, pinhole leaks, cracks, moisture and evidence of over-

the-surface arc tracking. Otherwise, short circuiting could cause

ignition problems. If any of these conditions exist, replace with

new porcelain insulators (Replacement kit P/N 269820).

• If a need for service or replacement is determined, see

instructions on page 32.

5. Reassemble

• Check the gasket. If in tact, position it over the studs. If damaged,

replace with like replacement.

• Line the burner up with the studs and slide the tube into the

heater.

• Using the nuts and washers, attach the burner mounting ange.

• Re-connect the yellow wires to the ignition controller.

Loading...

Loading...