24 Culligan® CSM Series Softeners

24 Cat. No. 01016370

Tubing Installation

The tubing assembly is shipped in the same carton as the controller. The tubing is suppled in lengths pre-cut to connect

up to a 3” Brunermatic valve.

1. Using the tubing supplied, interconnect the controller, Brunermatic valve, brine line diaphragm valve (multiple

units), and any accessory kits ordered with the system. Refer to Figure 35, Figure 36, and Figure 38 for system

tubing diagrams.

2. For ease of installation, some tube fittings on the system are the push-in type. Tubing is simply inserted into the

fitting collet to make a secure, leak free connection. Refer to Figure 33 and Figure 34 for details on proper con-

nection and disconnection.

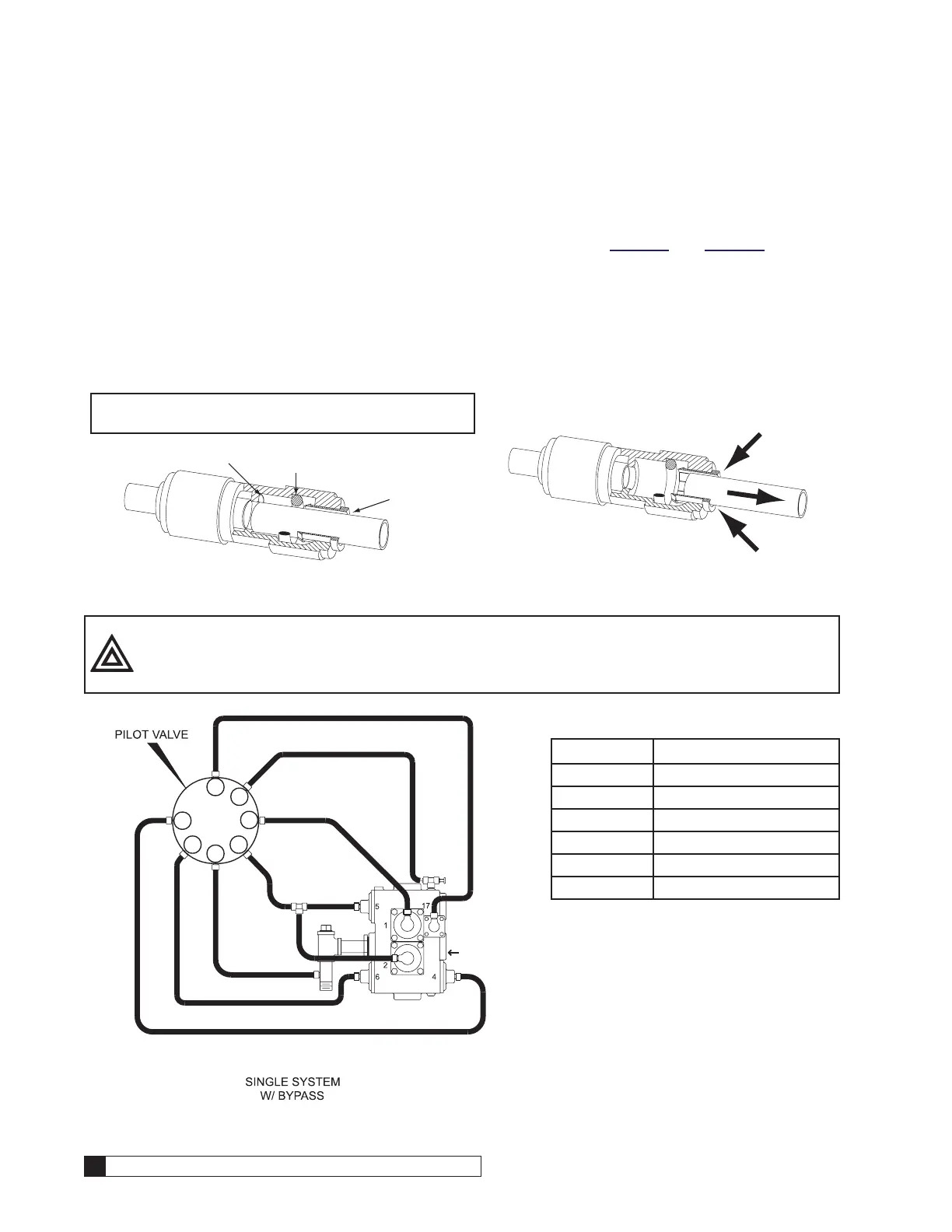

CONNECTION

To make a connection, simply push the tubing in by hand.

NOTE the fitting will grip before it seals. Make certain

the tubing is fully pushed into the tube stop.

TUBE STOP

O-RING

COLLET

Figure 33.

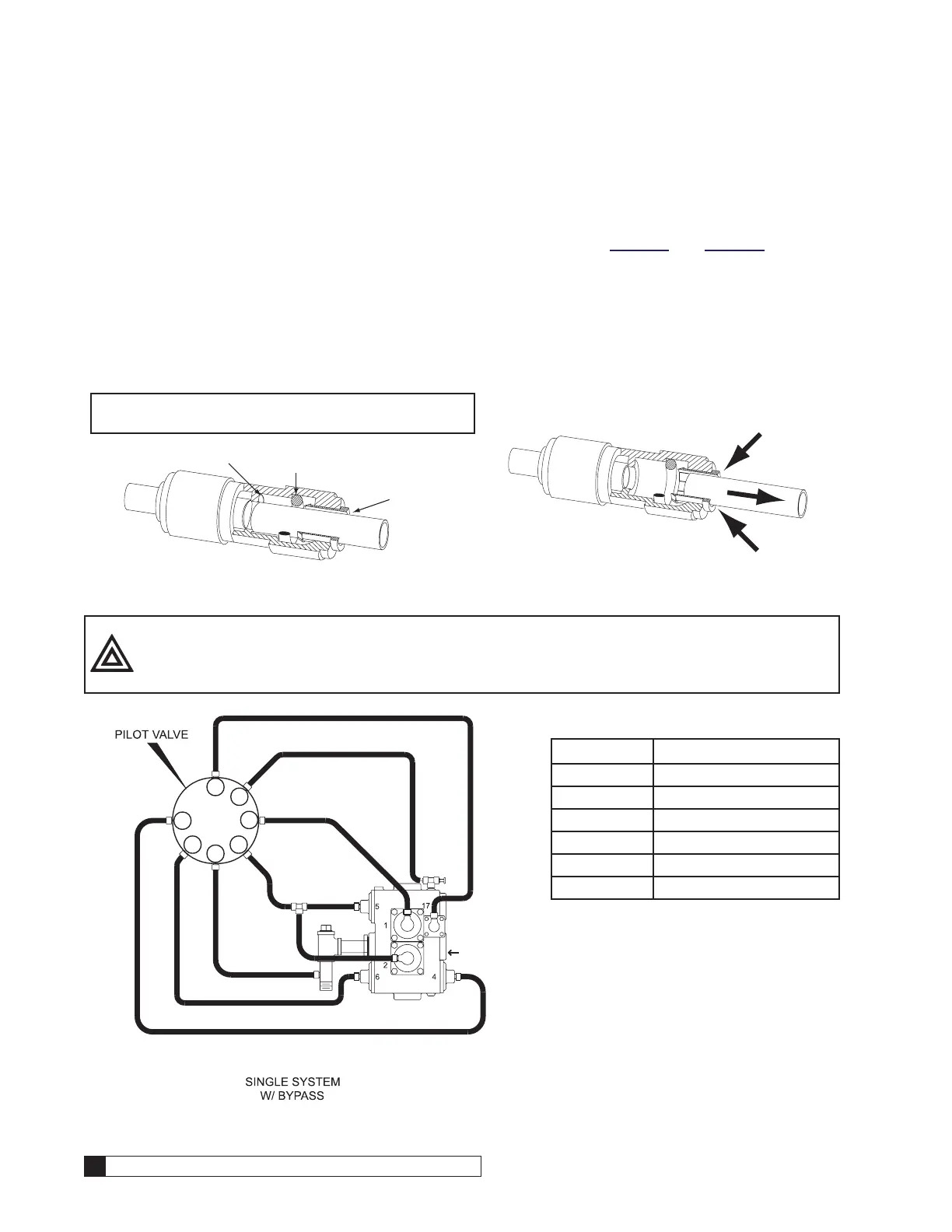

DISCONNECTION

To disconnect tubing, push in the collet against the face

of the fitting. With the collet held against the face of the

fitting, the tubing can be removed.

Figure 34.

CAUTION! The port numbers on the Brunermatic valve may not coincide with the ports

on the MVP pilot valve. Refer to the port numbering chart for cross-reference

information.

6

P

DR

1

3/4

2

5

Brunermatic

Valve

Figure 35.

Table 7. Cross Reference Port Chart

Pilot Valve Brunermatic Valve

1 1

3 2

2 4

4 5

5 6

6 17

Loading...

Loading...