16

CYLINDER TRAVEL AND BENDER CALIBRATION

1. The bender must be calibrated prior to bending. To calibrate, rotate the pump

valve lever to the closed position and activate the pump to advance the

hydraulic cylinder until the shoe, conduit and follow bar tighten up. Stop the

pump and DO NOT advance the cylinder far enough to start a bend.

2. Read the measurement on the gauge rod and compare that with the 0˚ (tight)

number for the appropriate conduit type and size on the charts below. If there

is a difference in these two numbers, that difference must be included in the

cylinder travel measurements for that type and size of conduit.

CYLINDER TRAVEL ( APPROXIMATE )

EMT CONDUIT

DEGREE OF BEND 2 1/2" (90°) 3" (90°) 3 1/2" (90°) 4" (90°)

0°

(tight)

4

3

⁄16 3

7

⁄8 2

7

⁄8 2

3

⁄16

10°

4

7

⁄8 4

7

⁄8 3

15

⁄16 3

3

⁄8

15°

5

3

⁄16 5

3

⁄16 4

3

⁄8 3

3

⁄4

30°

6

1

⁄8 6

1

⁄4 5

7

⁄16 4

7

⁄8

45°

7

1

⁄16 7

1

⁄8 6

1

⁄2 6

1

⁄16

60° 8

8

3

⁄16 7

5

⁄8 7

3

⁄16

90°

9

1

⁄2 10

3

⁄8 9

7

⁄8 9

1

⁄2

IMC CONDUIT

DEGREE OF BEND 2 1/2" (90°) 3" (90°) 3 1/2" (90°) 4" (90°)

0°

(tight)

2

7

⁄8 2

1

⁄4 1

5

⁄8 1

1

⁄16

10° 4

3

9

⁄16 2

15

⁄16 2

7

⁄16

15°

4

3

⁄8 4

1

⁄16 3

7

⁄16

3

30°

5

3

⁄16 5

5

⁄8 4

7

⁄8 4

5

⁄8

45°

7

5

⁄16 7

3

⁄16 6

3

⁄8 6

1

⁄4

60°

8

3

⁄4 8

9

⁄16 8

1

⁄16

8

90°

11

3

⁄16 11

13

⁄16 11

1

⁄4 11

1

⁄4

RIGID CONDUIT

DEGREE OF BEND 2 1/2" (90°) 3" (90°) 3 1/2" (90°) 4" (90°)

0°

(tight)

2

7

⁄8 2

5

⁄16 1

7

⁄16

1

10°

3

13

⁄16 3

9

⁄16 2

13

⁄16 2

3

⁄8

15°

4

5

⁄16

4

3

5

⁄16 2

15

⁄16

30°

5

11

⁄16 5

7

⁄16 4

13

⁄16 4

5

⁄8

45°

7

1

⁄8 7

1

⁄16 6

3

⁄8 6

3

⁄16

60°

8

9

⁄16 8

11

⁄16 7

13

⁄16 7

13

⁄16

90°

11

1

⁄16 11

3

⁄4 10

7

⁄8 11

1

⁄8

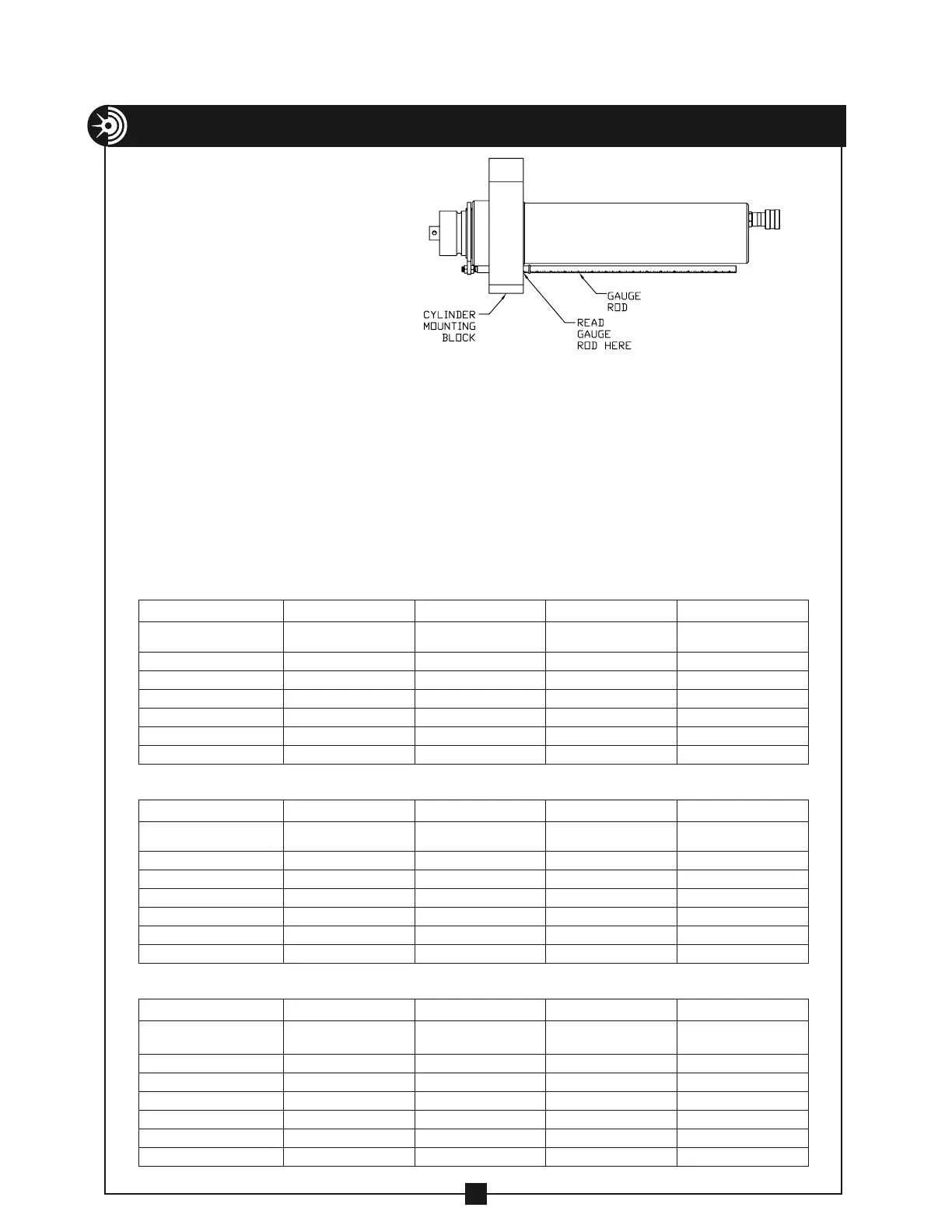

NOTE: Read the gauge rod at the

edge of the cylinder mounting

block. Gauge rod should read zero

(ø) when cylinder is fully retracted.

Loading...

Loading...