12

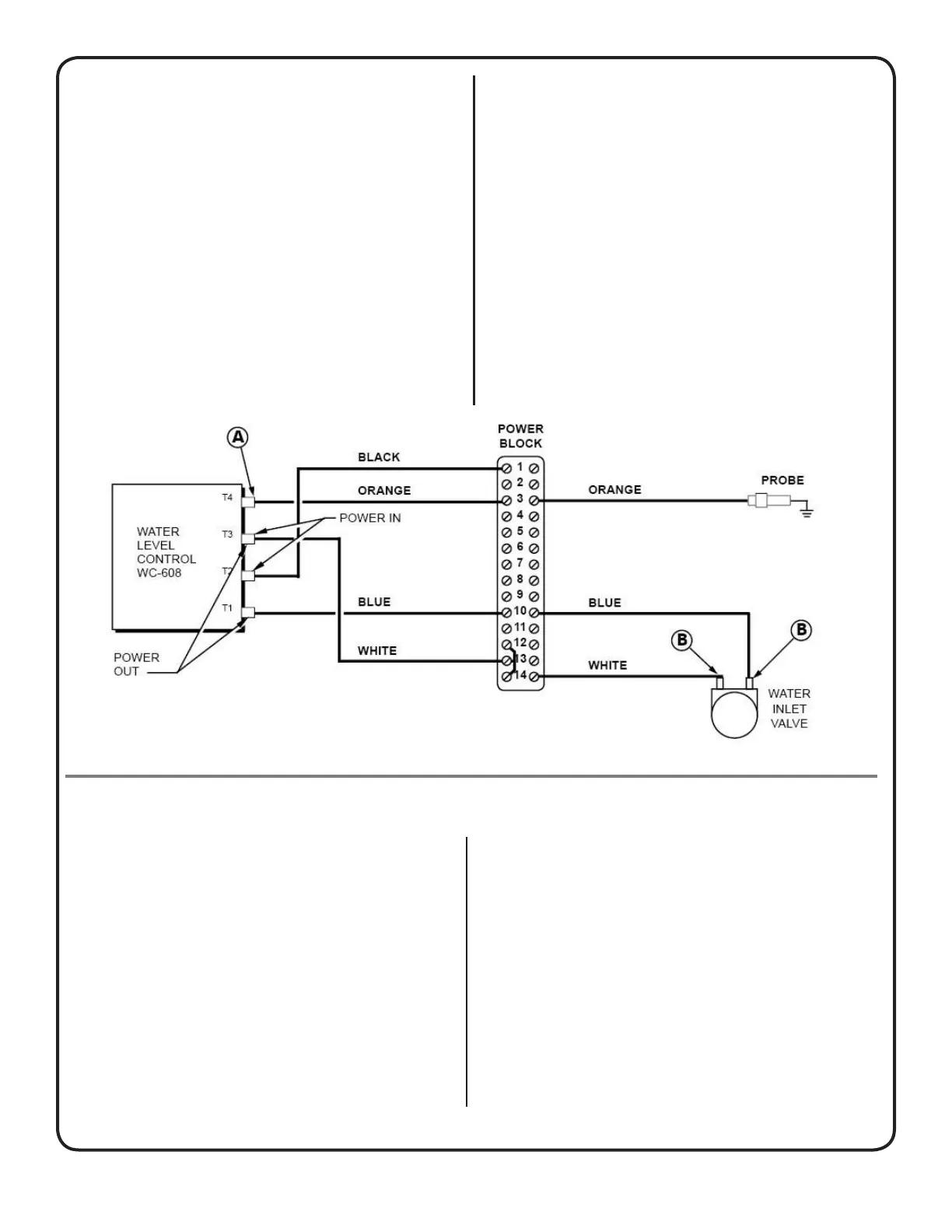

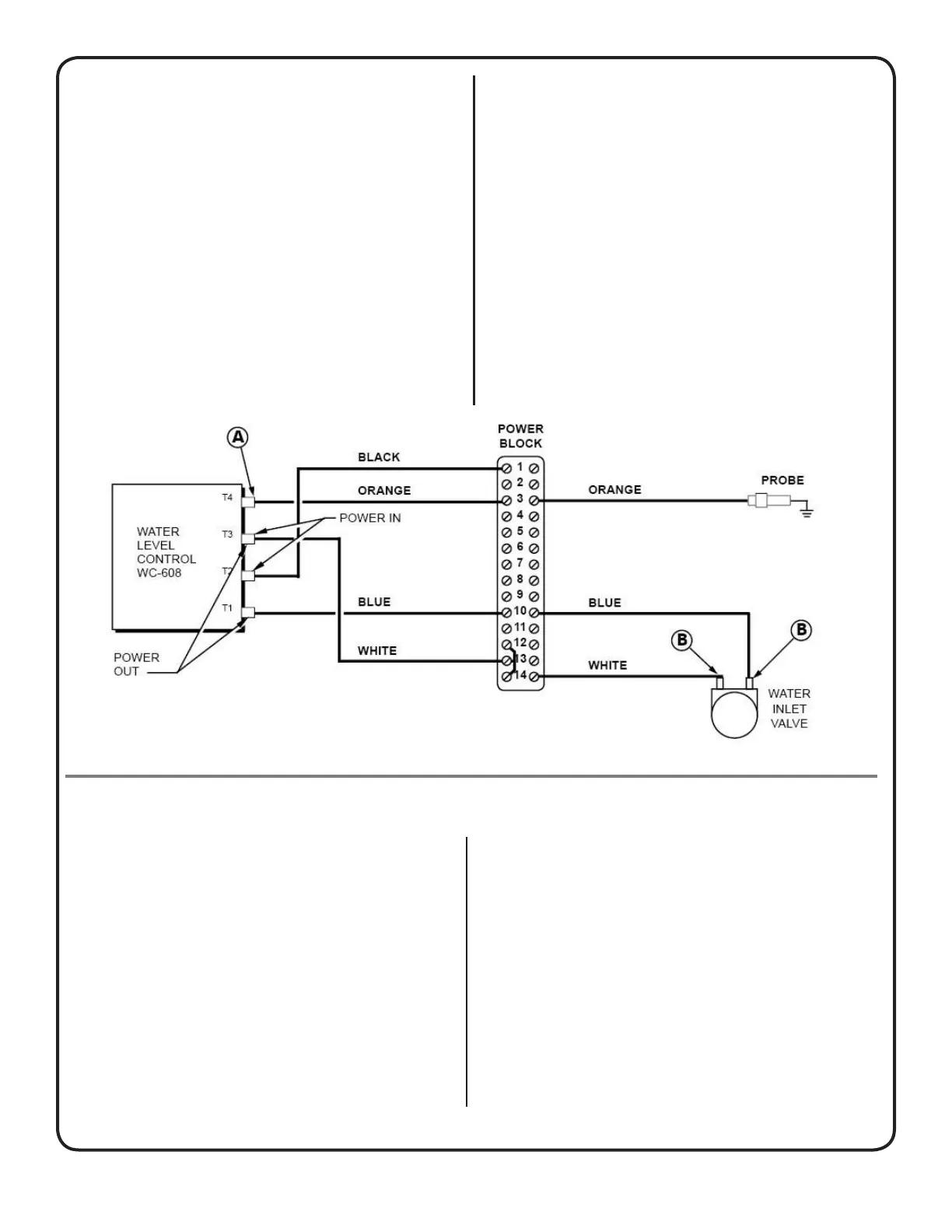

power to the valve solenoid and the valve does not open.

Replace the board.

III. If both the probe and the liquid level control board are

functioning normally, check the water inlet valve.Turn

on the unit and disconnect the white and the blue wires

from the coil on the valve (points Bofgure9).Usea

lamp cord with alligator clips; hookup the terminals to

the cord. Plug the cord into a 120 volt outlet. The valve

should open when plugged in and close when unplugged.

Repeat this three or four times. If you don’t hear the

sound of the solenoid, then the coil is bad. If you hear

waterowingthroughthevalvewhenunplugged,the

diaphragm is either torn or needs cleaning. Replace the

coil, diaphragm or clean out the valve.

Figure 9. Water Level Control System.

the quick disconnect terminal attached to the orange

wire and with the other lead of the meter, touch the metal

surface of the urn shell. Any reading in the meter dial will

indicate the presence of a ground in either the terminals,

wire, or probe assembly. Find the ground and repair it. If

there is no reading at all on your ohmmeter, the probe is

okay. Return the orange wire to the terminal 4 of the liquid

level control board where it was removed.

II. Turn the unit on and clamp the leads of your voltmeter at

the terminals of the valve coil as shown at Bofgure9.

Under normal conditions, the voltmeter should read 110

to120voltswhiletheurnisllingupandpowertothe

coil should stop once the water level reaches the probe

tip. If the voltmeter does not show voltage, the liquid level

control board is not working properly. It is not sendin

BREWING OPERATION

Components Involved: Fuse, Brew Switch, Hold-

ing Relay, Timer, Stop Switch and Water Pump.

PROBLEM: Brew switch light does not turn on

when pressed.

Test: Check your power supply and fuse in con-

trol box. It may be burned out.

Problem: Brew switch does not stay on, or light

stays on only while switch is pressed but turns

off when released and water comes out of spray

head only while the switch is kept pressed.

Test Brew Switch: Take a voltage reading at

points A of Fig. 10 while the brew switch is

pushed in. If you read 110 volts, that means the

switch is good.

Also, read voltage at points B of Fig. 10 to see if

the coil of holding relay is being energized.

Test Holding Relay: The relay is used to ener-

gize the water pump, and the timer, therefore a

simple voltage reading across C in the terminal

strip will show if the relay is opening and closing

its contacts. A zero reading will indicate a faulty

relay. By the process of elimination, so far we

established that the brew switch, and relay are

working properly but the problem still remains.

Test Timer: The timer resets itself to the N. C.

Loading...

Loading...