13

position after every brewing cycle but if it fails to

stop itself, it will remain open and cause the prob-

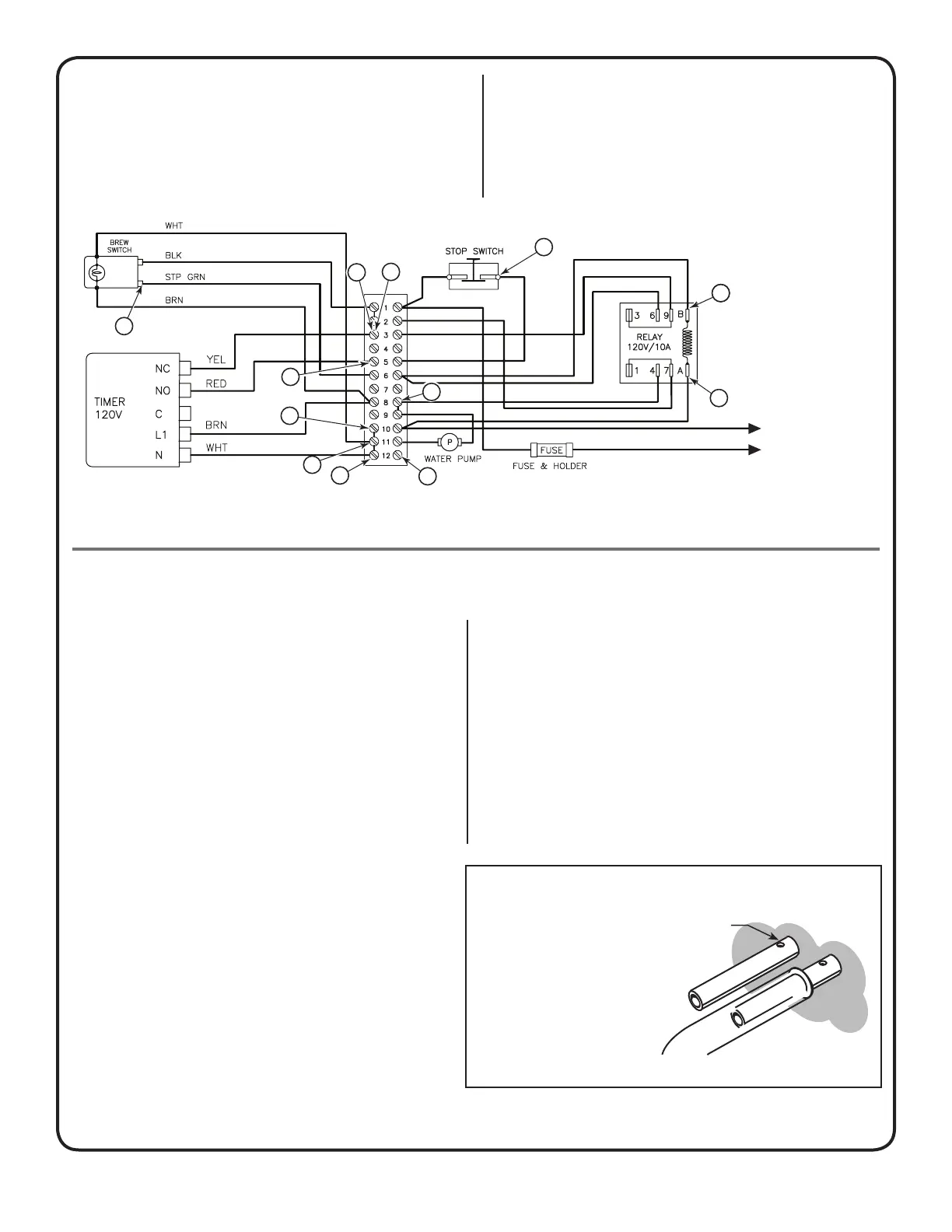

lem in question. To check the timer, disconnect

yellow and red wires at E and take a continuity

test between the two wires. If there is no continu-

ity, the switch is open and must be replaced.

Test Stop Switch: The last of the components in-

volved in this operation is the stop button. Its only

function is to interrupt the current that energizes

the coil of the holding relay after the brew switch

has been depressed. A voltage reading at points

F will indicate an open or closed condition.

AERATION SYSTEM

Components Involved:

1. Aeration Switch

2. Holding Relay

3. Air Pump

AUTOMATIC AERATION

PROBLEM: Only one of the liners is aerated.

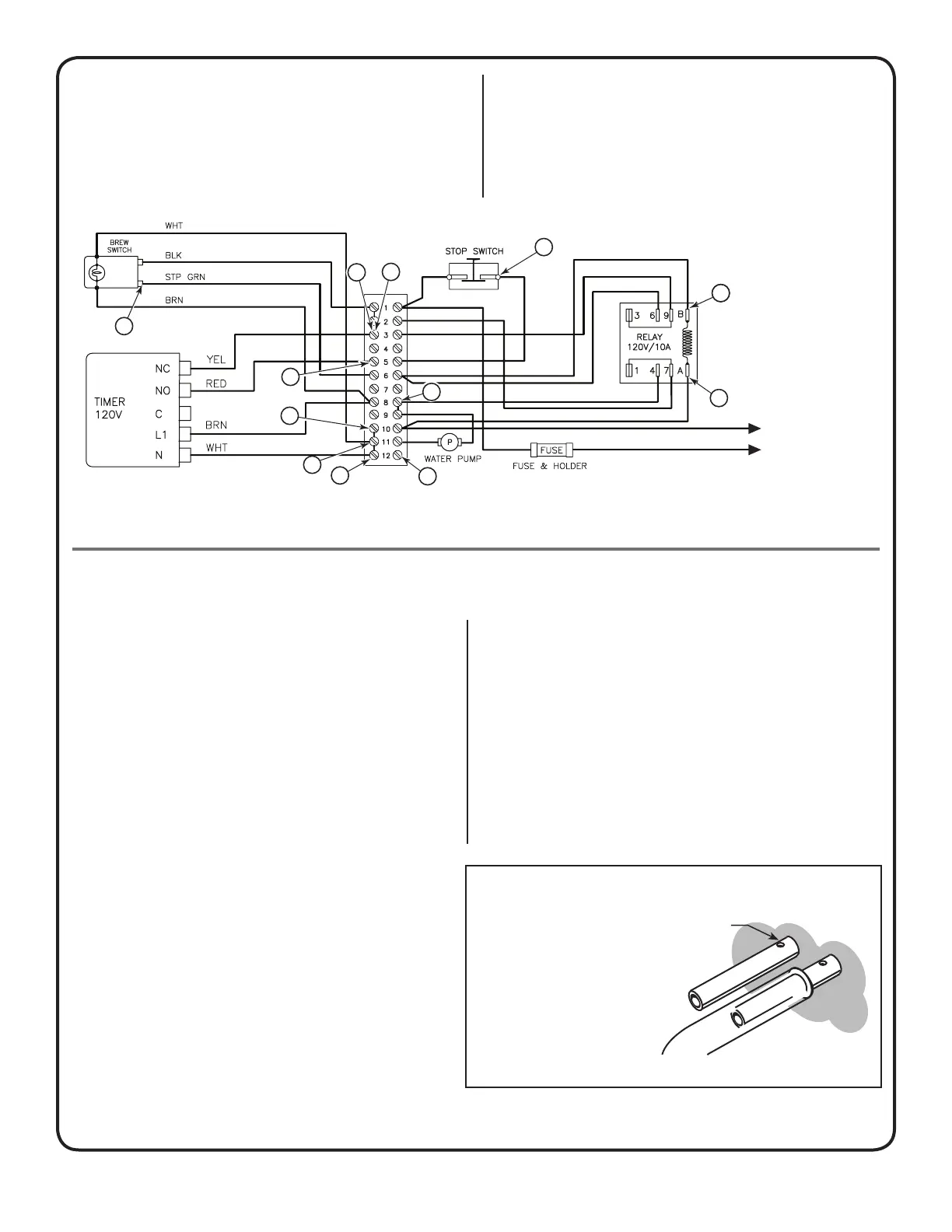

TEST: Inside the control box, there are two

silicone tubes connecting the aeration pump to

the ¼” copper tubes coming from inside the urn.

Carefully, pull the silicone tubes from the cop-

per tubes, press the manual aeration button and

using your hand, feel for air pumping out from the

silicone tubes. Determine if the pump is working.

Replace the pump if air does not blow through the

tubes.

These are air release holes

so that after air is pumped

into the liner, coffee can

rell the gauge glass.

NOTE: When replacing the silicone tubing on the

copper tubes, make sure you do not cover the

small holes on the copper tubes.

MANUAL AERATION

PROBLEM: Manual aeration is not present on

either of the liners, yet automatic aeration operates

normally.

TEST: Check the continuity of the manual aera-

tion switch. Check to see that the BLACK wire runs

from terminal 1 of terminal strip #1 to the switch and

YELLOW wire runs from the switch to terminal strip

#2. Check for clean, tight connections at all termi-

nals.

L1

L2

TO POWER

BLOCK, CORD OR

TRANSFORMER

B

C

C

A

A

B

B

D

D

E

E

F

Figure 10. Brewing Operation

F

Figure 11. Air Pump Tubes.

Loading...

Loading...