ENGLISH

GB

70

entrance at a depth of at least 30cm below the water level and

must be watertight along its whole length, as far as the entrance

to the electropump.

7KHVXFWLRQDQGGHOLYHU\SLSHVPXVWEH¿WWHGVRWKDWWKH\GRQRW

exert any mechanical pressure on the pump.

2.1.2 Loading Operation

Installation above head and below head

Installation “above head” (par. 2.1.1): access the technical compart-

ment and, with the aid of the accessory tool (Fig.3_point 5) or with a

VFUHZGULYHUUHPRYHWKH¿OOLQJFDS)LJBSRLQW)LOOWKHV\VWHPZLWK

clean water through the loading door, taking care to let the air out. If the

non-return valve on the suction pipe (recommended in paragraph 2.1.1)

has been placed close to the system entry door, the quantity of water

ZLWKZKLFKWR¿OOWKHV\VWHPVKRXOGEHOLWUHV,WLVUHFRPPHQGHGWR¿W

the non-return valve at the end of the suction pipe (foot valve) so as to

EHDEOHWR¿OOLWTXLFNO\WRRGXULQJWKHORDGLQJRSHUDWLRQ,QWKLVFDVHWKH

quantity of water necessary for the loading operation will depend on the

length of the suction pipe (2.2 litres + …).

Installation “below head” (par. 2.1.1): if there are no check valves

between the water deposit and the system (or if they are open), it loads

automatically as soon as it is allowed to let out the trapped air. So slack-

HQLQJWKH¿OOLQJFDS)LJBSRLQWHQRXJKWRYHQWWKHWUDSSHGDLUDOORZV

the system to load completely. You must survey the operation and close

the loading door as soon as the water comes out (however it is recom-

PHQGHGWR¿WDFKHFNYDOYHLQWKHVHFWLRQRIWKHVXFWLRQSLSHDQGWRXVH

it to control the loading operation with the cap open). Alternatively, in the

case where the suction pipe is intercepted by a closed valve, the loading

operation may be carried out in a similar way to the one described for

installation over head.

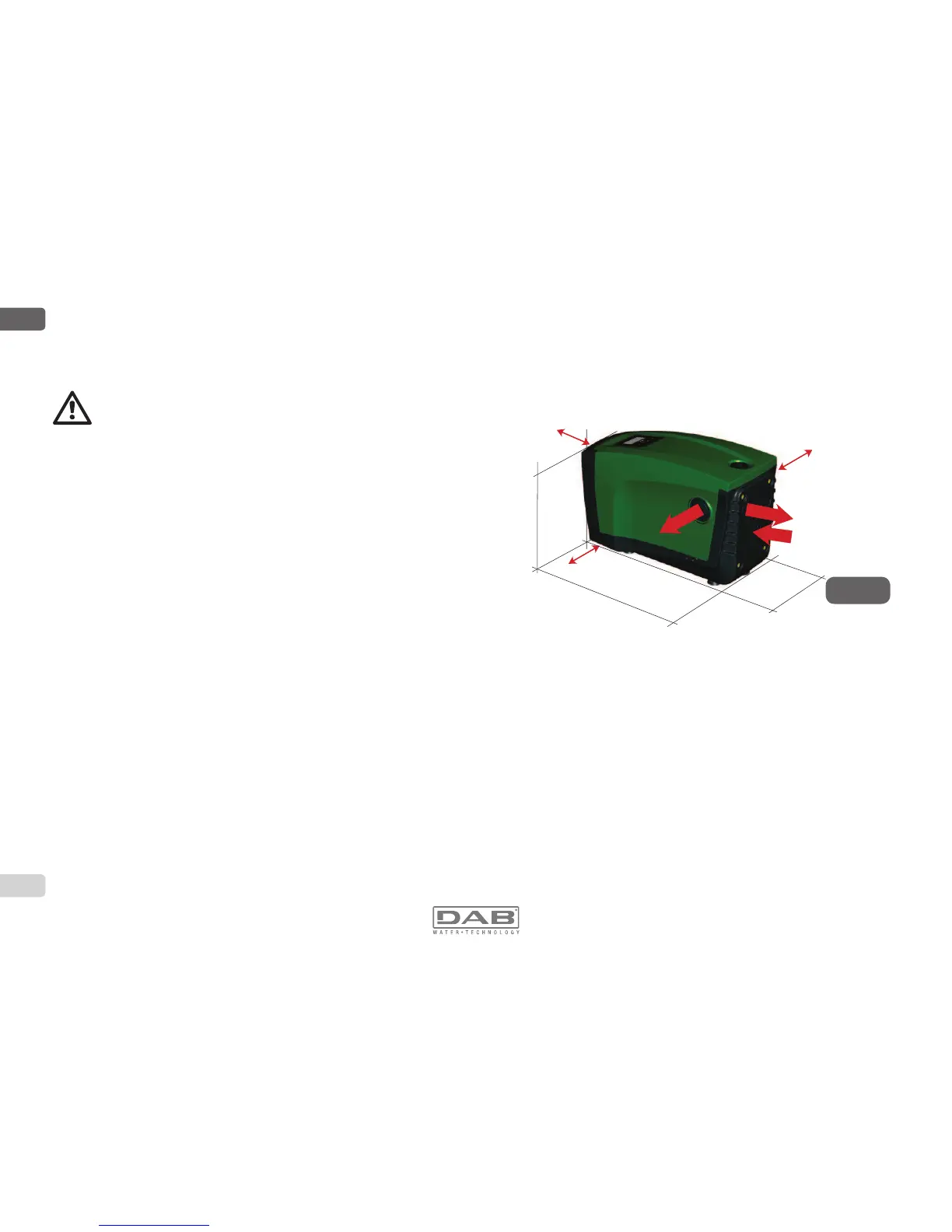

2.2 - +RUL]RQWDO&RQ¿JXUDWLRQ

Remove the 4 support feet from the bottom tray of the packaging and

screw them fully into their brass seats on face E. Put the system in place,

taking into account the dimensions in Fig.10.

7KHGLVWDQFHRIDWOHDVWPPEHWZHHQ)DFH%RIWKHV\VWHP

and an obstruction is recommended so as to be able to carry out

maintenance on the non-return valve without disconnecting the

system.

7KHGLVWDQFHRIDWOHDVWPPEHWZHHQ)DFH$RIWKHV\VWHP

and an obstruction is recommended so as to be able to remove

the door and gain access to the technical compartment.

7KHGLVWDQFHRIDWOHDVWPPEHWZHHQ)DFH'RIWKHV\VWHP

and an obstruction is obligatory to let out the power supply cable.

,IWKHVXUIDFHLVQRWÀDWXQVFUHZWKHIRRWWKDWLVQRWWRXFKLQJDQGDGMXVW

its height until it contacts the surface so as to ensure the stability of the

system. The system must in fact be placed in a safe and stable position,

ensuring that its axis is vertical: it must not be in an inclined position.

2.2.1 Hydraulic connections

Make the connection at input to the system through the mouth on Face C

marked “IN” in Fig.10 (suction connection). Then remove the respective cap

10 mm

200 mm

270 mm

OUT 1

OUT 2

IN

565 mm

370 mm

265 mm

Figure 10

Loading...

Loading...