- 27 -

Adjusting Procedure

1) Align to crank pulley with specified mark and

pointer.

2) Practice 1) of 1.5.10, page 25.

3) Release fixed nuts to 4 injection pump.

4) When rapid injection timing,

rotate injection pump toward right side.

When reduce the injection timing,

rotate injection pump toward left side.

NoteWhen mark slip 1mm, injection

timing differ about 2˚.

5) As operating of fuel feed pump, rotate

injection pump at the same time, and then

stop injection pump and fuel feed when stop

fuel from #1 delivery holder.

6) Fix fixed nut of 4 injection pump.

7) Tighten installed inside parts with specified

torque after remove #1 delivery valve holder.

8) Tighten installed injection pipe with specified

torque.

EJM1045S

9) Remove delivery valve holder from #1

plunger.

10) Assemble the delivery valve intenal parts at

the devilvery valve holder.

11) Assemble the delivery valve holder

assembly to #1 plunger and tighten with the

specified torque.

12) Assemblel the #1 cylinder injection pipe

and tighten with the specified torque.

CAUTION

Tighten with the specified

torque.

Injection pump which was

manufactured aluminum,

so that why too much

tightening will be damaged

body and related parts.

EJM1041S

Delivery Valve Holder Torque 4.250.25 kgm

Injection Pipe Nut Torque 3.10.2 kgm

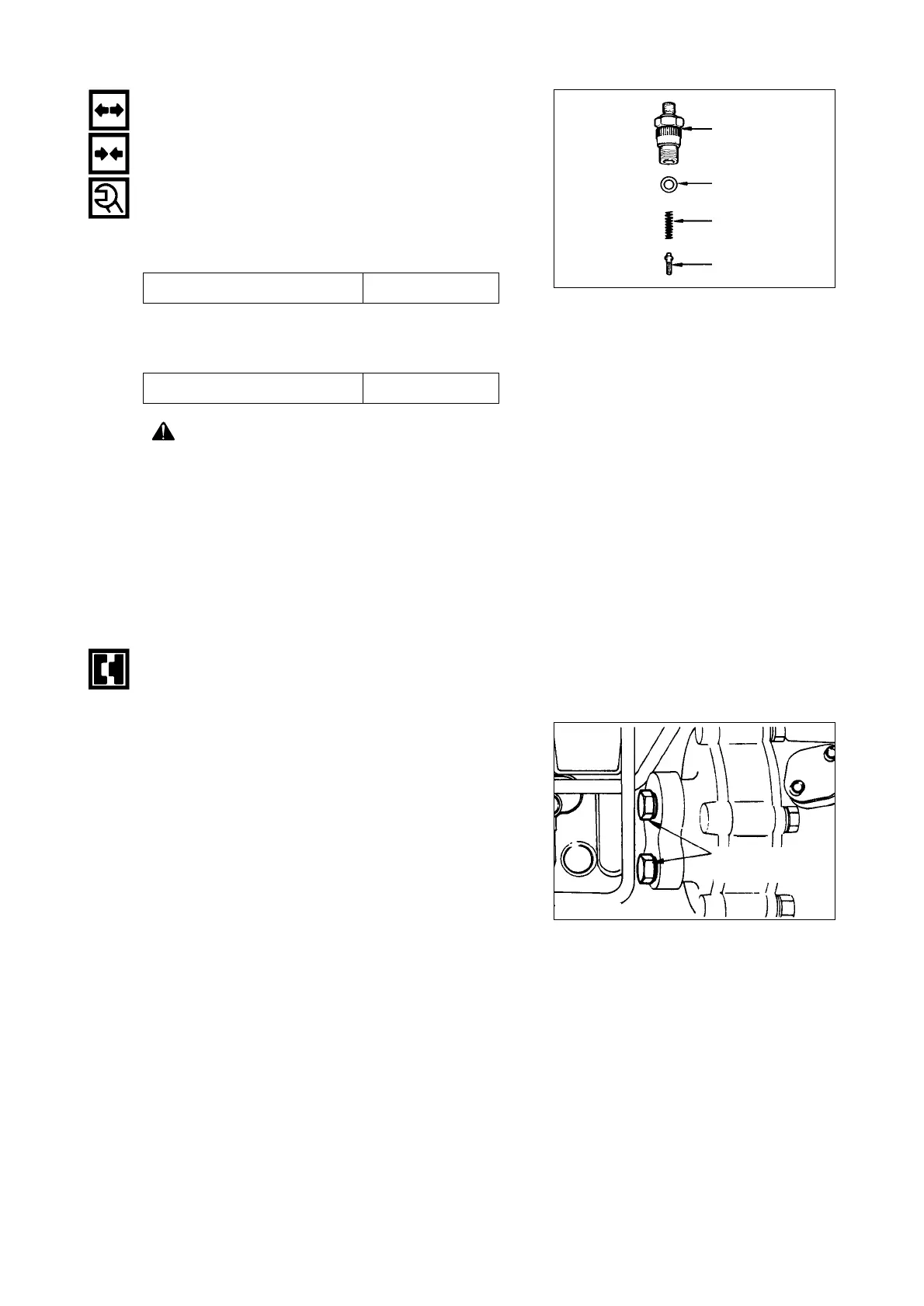

Holder

Seat

Spring

Delivery Valve

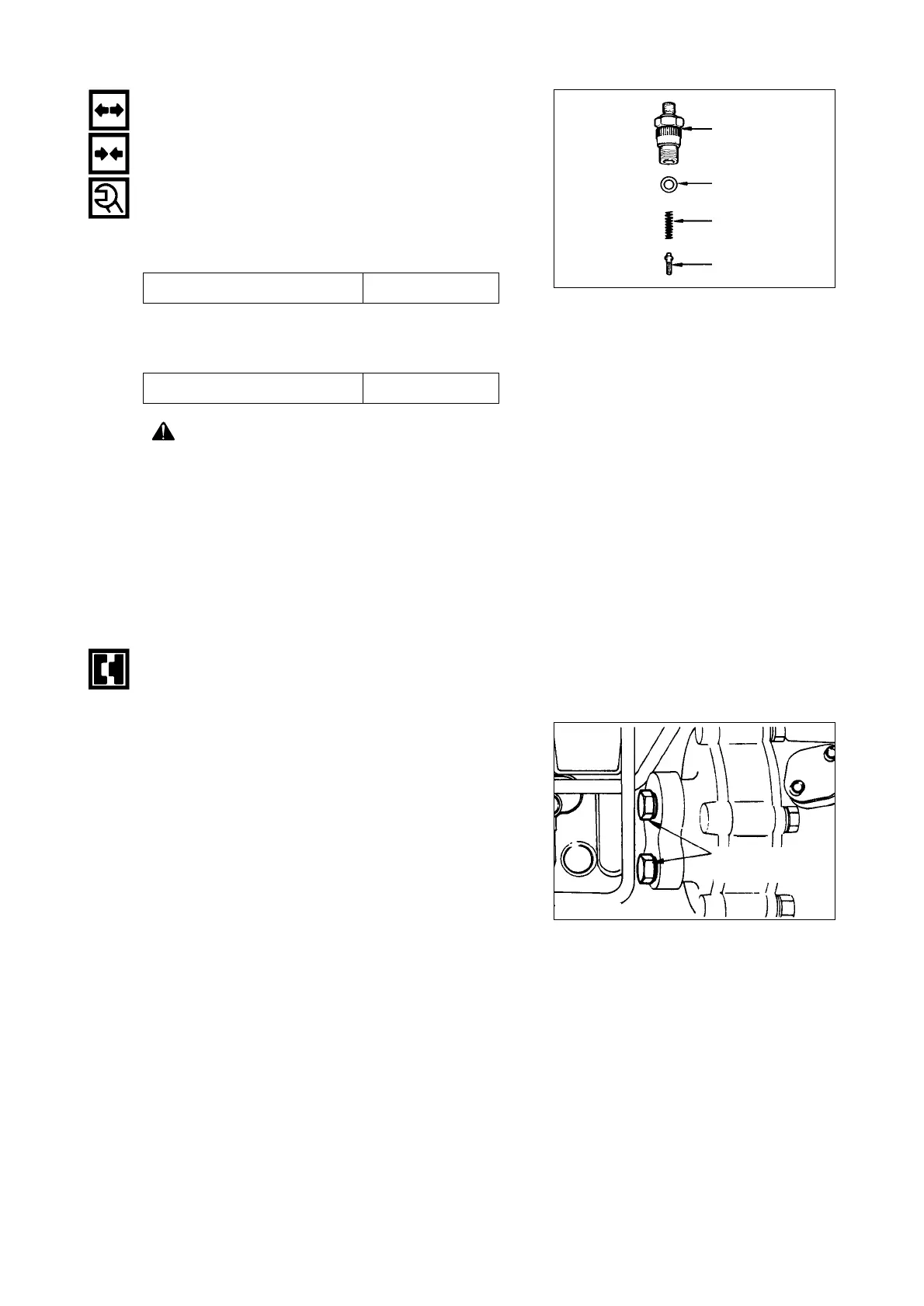

Relaxity of

whole nuts

Loading...

Loading...