[Classification]

∙A type :

∙B type : or

- 66 -

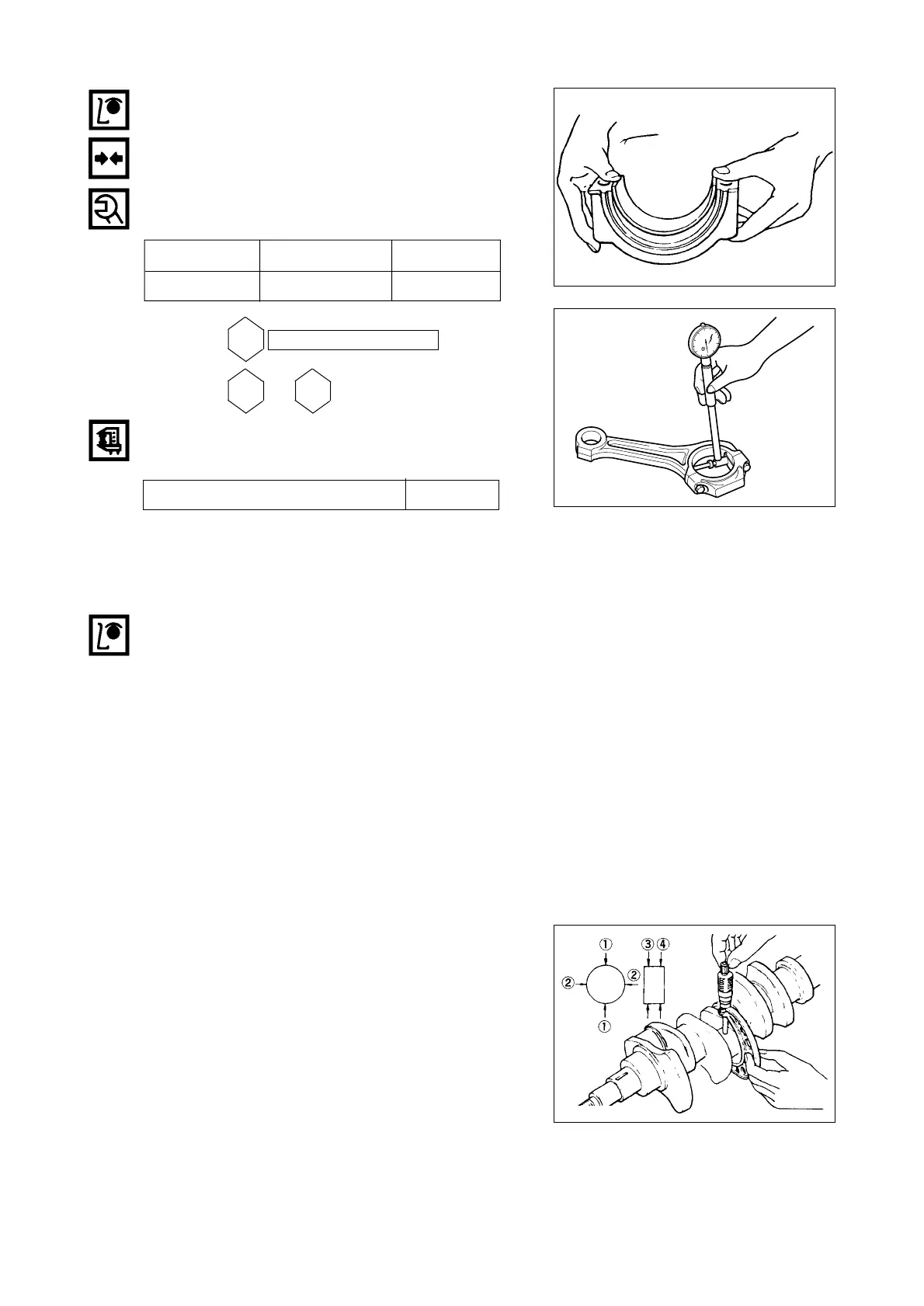

Check of Connecting Rod Bearing

1) Assemble the bearing to connecting rod cap.

2) Check the tension of connecting rod bearing.

Replace the bearing if it is lack of tension.

3) Tighten the connecting rod bearing cap with

the specified bolt torque.

4) Measure an inside of connecting rod bearing

with an inside of dial gauge.

2.3.12. Crankshaft

Crank shaft and Bearing Inspection

Check of Crank shaft and bearing

1) Check the crank shaft journal surface pin

part whethere excessive wore and damaged

or not.

2). Check assembled front & rear end of oil

seal part for oil seal assembled part

whethere exesive wore and damaged or

not.

3) Replace or repair the crank shaft when crank

shaft found excessive wore or damaged.

4) Check the obstruction of crank shaft oil port.

5) Blow hard high pressured air into oil port if

necessary.

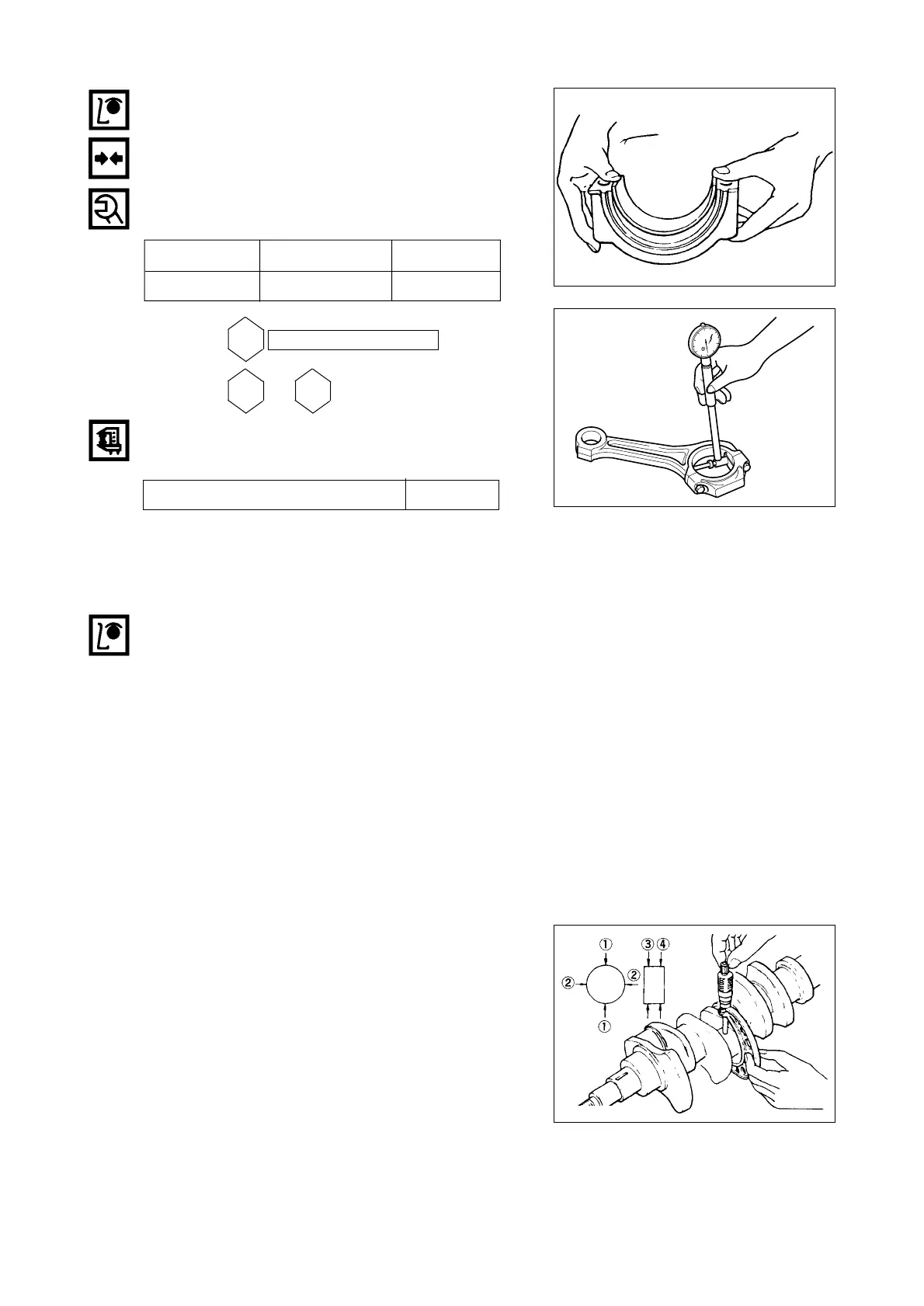

Crank shaft Journal and Crank pin

Outside Diameter

1) Measure the crank shaft journal outside

diameter with the micrometer torward

①-①

and ②-②.

2) Measure from 2 point ③ & ④ when measure

crank shaft journal outside diameter.

3) Repeatedly practice item 1 & 2.

Grind if the pin and journal measured value

escaped from the specified limit.

EJM2091S

EDM2044I

EJM2093S

A type B type

Bolt Torque 12±0.25 9.75±0.25

marked on bolt head

Inside of connecting rod bearing 64 mm

Loading...

Loading...