G424 Service Manual LPG Fuel System76

Carburetor

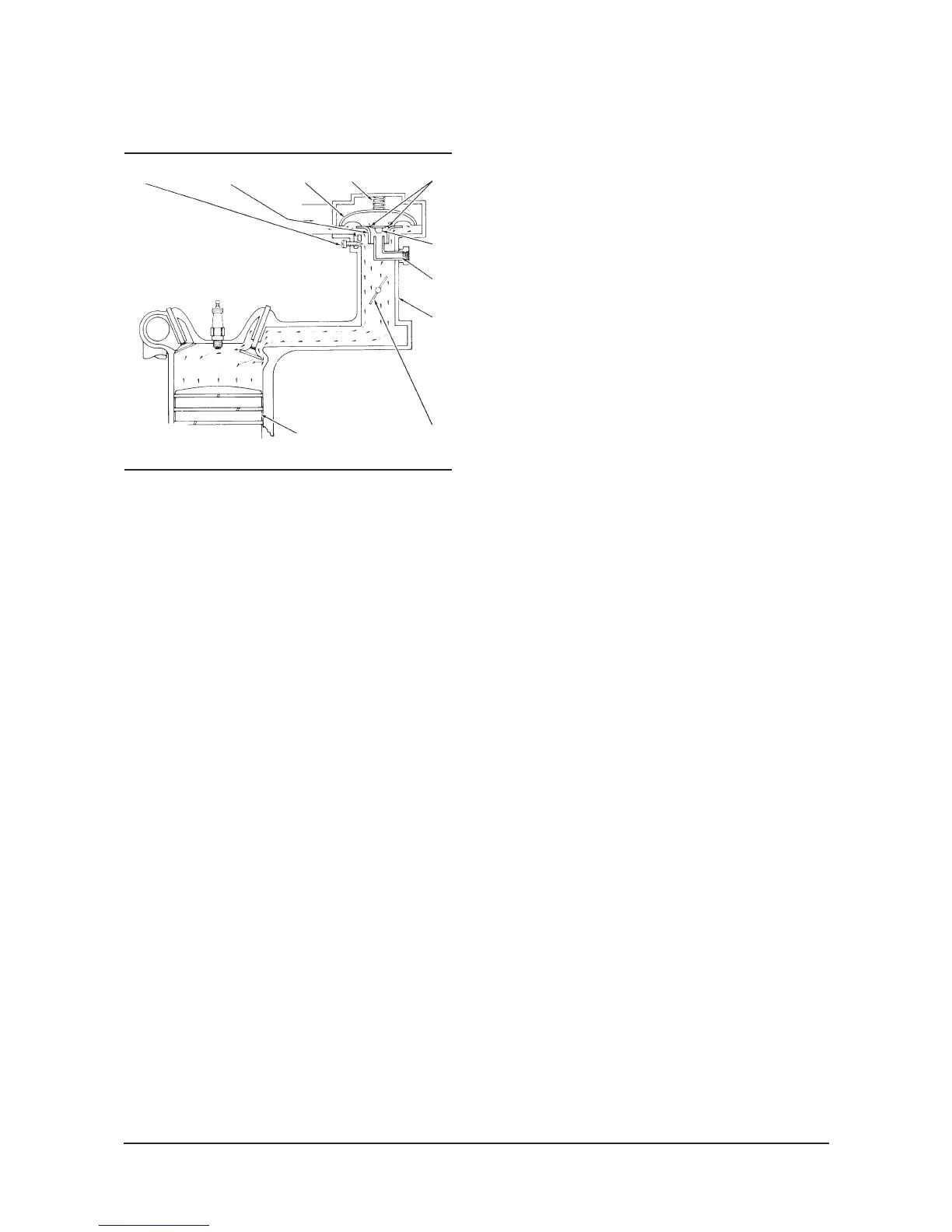

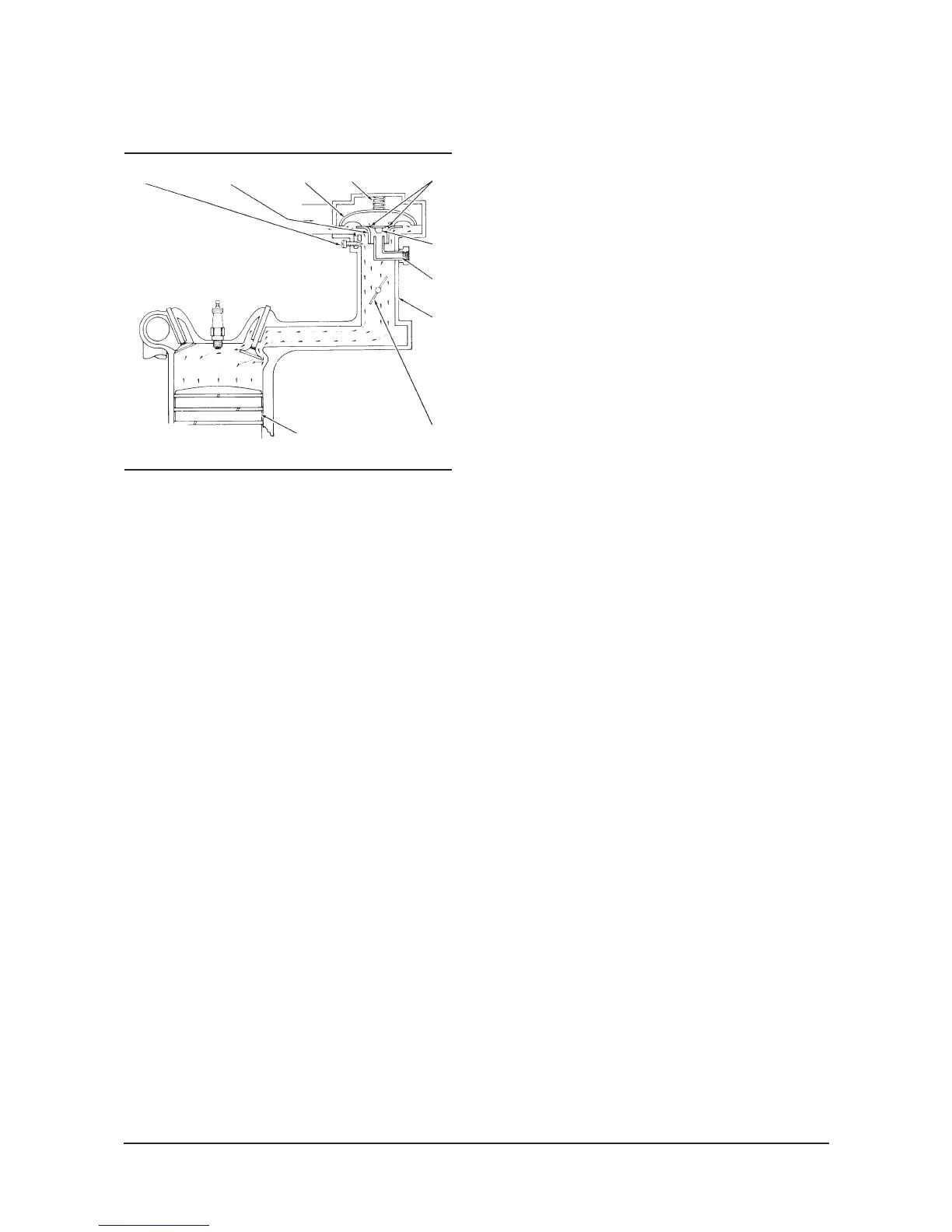

LP Fuel Carburetor Schematic

(1) Idle air screw. (2) Air valve. (3) Diaphragm.

(4) Metering spring. (5) Passage. (6) LP gas metering valve.

(7) Power mixture adjustment. (8) Carburetor. (9) Piston.

(10) Throttle valve.

Lift trucks with LP (Liquid Petroleum) fuel system use

an air valve type of carburetor (8). The operation of the

carburetor controls the fuel mixture flow into the

engine with the movement of throttle valve (10) and

mixes the air flow with the LP fuel flow.

The air flow is measured by the operation of air valve

(2) in the carburetor bowl. The stronger the air flow

through the carburetor, the higher the air valve moves

up. LP gas metering valve (6) is connected directly to

air valve (2). As the air valve moves up, LP gas

metering valve (6) also moves up. LP gas metering

valve (6) is shaped to let in the correct amount of LP

gas at any height related to air valve (2) upper

movement. The air valve activates a pressure drop

which gives a very high metering force (measured

suction) to the fuel that flows in the carburetor at low

engine speeds and it permits easy starting. At full

engine speeds, the air valve is at the top of its upper

movement. The valve then becomes an inverted (up

side down) venturi and will let a large amount of air

pass through.

When starting the engine, the intake stroke of piston

(9) causes lower than atmosphere pressure (vacuum)

in the carburetor. The vacuum is felt through passage

(5) in air valve (2) and in the upper side of diaphragm

(3). As a result, the atmospheric pressure flows in the

carburetor and pushes up on the diaphragm.

Diaphragm (3) is lifted against the down pressure of

metering spring (4). The vacuum that is felt on

diaphragm (3) is variable according to engine speed

and the position of throttle valve (10) opening. Air

valve (2) measures the air flow that goes into the

engine, respective to the demands of the engine and

throttle valve (10) position.

The air pressure drop of 1.3 to 2.7 kPa (0.2 to 0.4 psi)

is controlled by metering spring (4) which permits the

force necessary to pull in the fuel into the air flow. LP

gas metering valve (6) is connected to the air valve

and lets in the correct amount of fuel from the LP

converter to mix with the air at any opening of the air

valve.

The carburetor is equipped with two limited mixture

adjustments. Idle air screw (1) directs atmosphere

(air) around the opening of air valve (2). As the idle air

screw is adjusted open, the air valve loses a little more

and causes the gas metering valve to close. The result

will be less fuel in the mixture at idle. The second

adjustment is power mixture adjustment (7). It controls

the fuel mixture when gas metering valve (6) is fully in

the up position. This adjustment is done only when the

engine is at a load condition. A CO meter or exhaust

analyzer is used for the power mixture adjustment.

This adjustment has no effect at idle or in the light load

range.

IDES070S

10

8

7

6

5

4

3

21

9

Loading...

Loading...