7 | Piping installation

Installer reference guide

34

2(A)MXM40+50 + 2(A)MXF40+50

R32 Split series

4P600463-2C – 2020.08

7 Piping installation

In this chapter

7.1 Preparing refrigerant piping................................................................................................................................................... 34

7.1.1 Refrigerant piping requirements ........................................................................................................................... 34

7.1.2 Refrigerant piping insulation.................................................................................................................................. 35

7.1.3 Refrigerant piping length and height difference ................................................................................................... 35

7.2 Connecting the refrigerant piping.......................................................................................................................................... 36

7.2.1 About connecting the refrigerant piping............................................................................................................... 36

7.2.2 Precautions when connecting the refrigerant piping............................................................................................ 36

7.2.3 Guidelines when connecting the refrigerant piping.............................................................................................. 38

7.2.4 Pipe bending guidelines ......................................................................................................................................... 38

7.2.5 To flare the pipe end.............................................................................................................................................. 38

7.2.6 Connections between outdoor and indoor unit using reducers........................................................................... 39

7.2.7 Using the stop valve and service port.................................................................................................................... 40

7.2.8 To connect the refrigerant piping to the outdoor unit ......................................................................................... 42

7.3 Checking the refrigerant piping.............................................................................................................................................. 42

7.3.1 About checking the refrigerant piping................................................................................................................... 42

7.3.2 Precautions when checking the refrigerant piping ............................................................................................... 43

7.3.3 To check for leaks................................................................................................................................................... 43

7.3.4 To perform vacuum drying .................................................................................................................................... 44

7.1 Preparing refrigerant piping

7.1.1 Refrigerant piping requirements

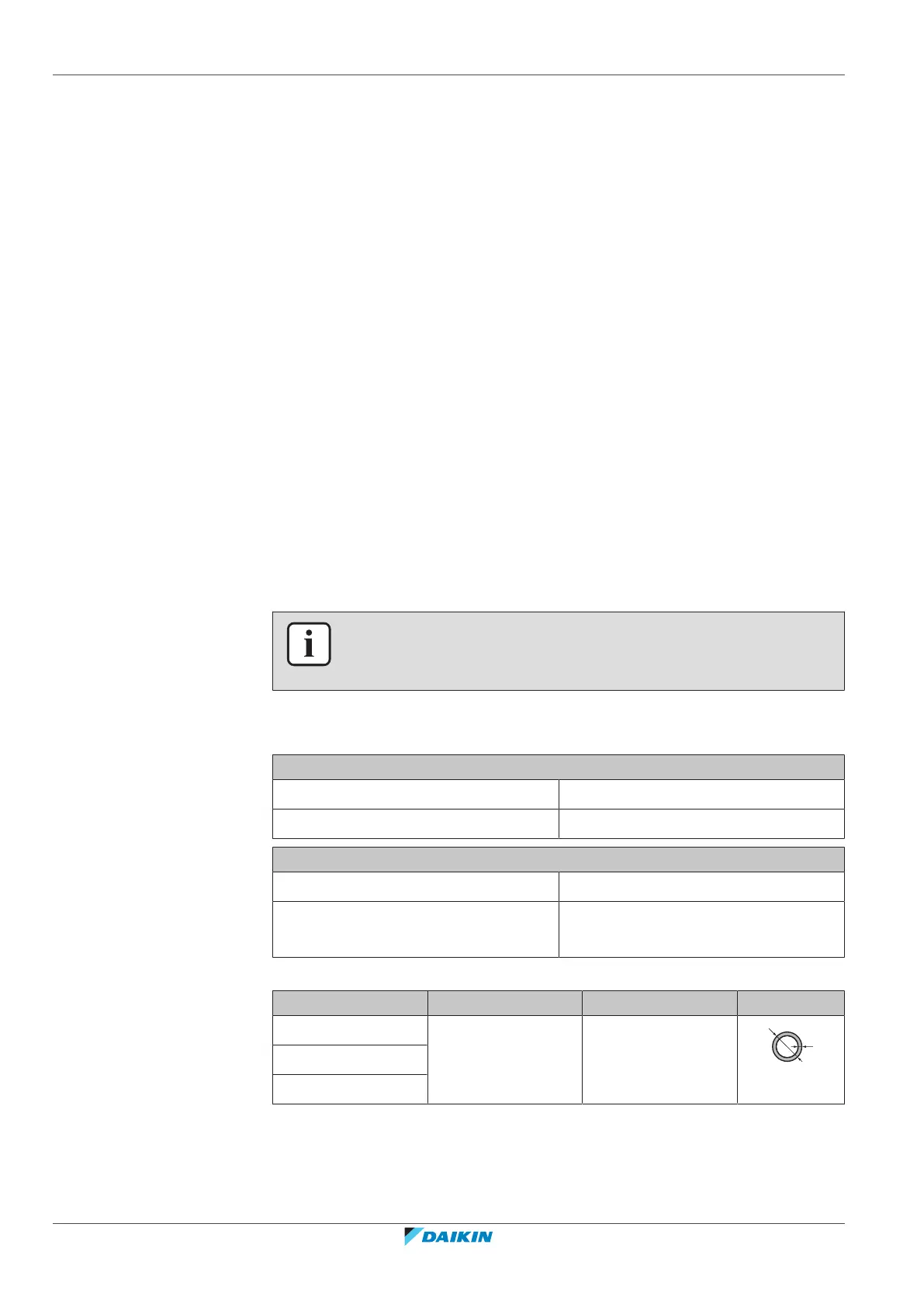

INFORMATION

Also read the precautions and requirements in the "2 General safety

precautions"[45].

▪ Piping material: Phosphoric acid deoxidised seamless copper.

▪ Piping diameter:

Class 40

Liquid piping 2× Ø6.4mm (1/4")

Gas piping 2× Ø9.5mm (3/8")

Class 50

Liquid piping 2× Ø6.4mm (1/4")

Gas piping 1× Ø9.5mm (3/8")

1× Ø12.7mm (1/2")

▪ Piping temper grade and thickness:

Outer diameter (Ø) Temper grade Thickness (t)

(a)

6.4mm (1/4") Annealed (O) ≥0.8mm

9.5mm (3/8")

12.7mm (1/2")

(a)

Depending on the applicable legislation and the maximum working pressure of the unit

(see "PS High" on the unit name plate), larger piping thickness might be required.

Usage of reducers might be required based on the indoor unit. See

"7.2.6 Connections between outdoor and indoor unit using reducers" [4 39] for

more information.

Loading...

Loading...