44

PRODUCT DESIGN

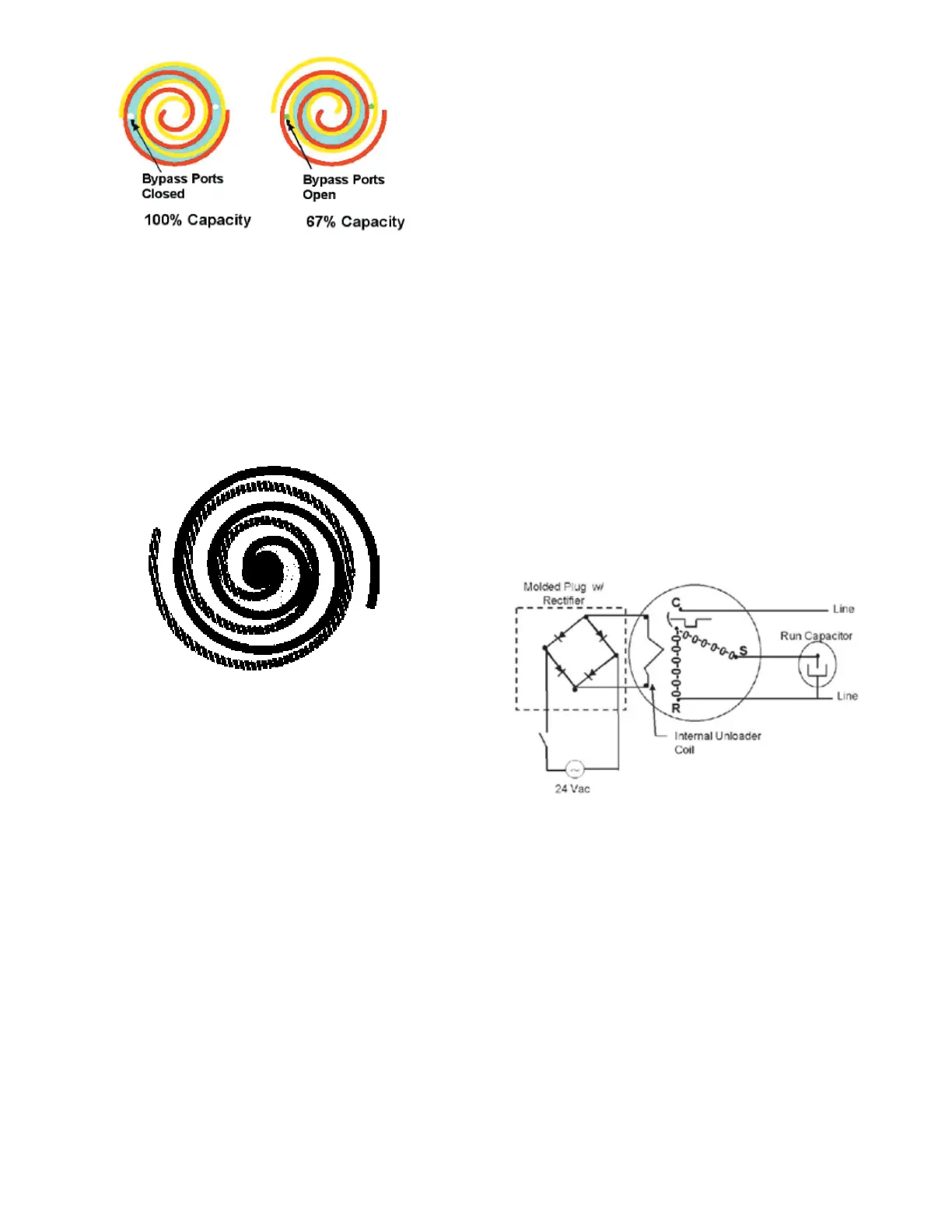

FIGURE A

A scroll is an involute spiral which, when matched with a mang

scroll form as shown, generates a series of crescent shaped gas

pockets between the two members.

During compression, one scroll remains staonary (xed scroll)

while the other form (orbing scroll) is allowed to orbit (but not

rotate) around the rst form.

As this moon occurs, the pockets between the two forms are

slowly pushed to the center of the two scrolls while simultane-

ously being reduced in volume. When the pocket reaches the

center of the scroll form, the gas, which is now at a high pres-

sure, is discharged out of a port located at the center.

During compression, several pockets are being compressed

simultaneously, resulng in a very smooth process. Both the

sucon process (outer poron of the scroll members) and the

discharge process (inner poron) are connuous.

Some design characteriscs of the Compliant Scroll compressor

are:

• Compliant Scroll compressors are more tolerant of liquid

refrigerant.

NOTE: Even though the compressor secon of a Scroll

compressor is more tolerant of liquid refrigerant, connued

oodback or ooded start condions may wash oil from the

bearing surfaces causing premature bearing failure.

• "Ultratech" Series scroll compressors use "POE" or polyo-

lester oil which is NOT compable with mineral oil based

lubricants like 3GS. "POE" oil must be used if addional oil is

required.

• Compliant scroll compressors perform “quiet” shutdowns

that allow the compressor to restart immediately without

the need for a me delay. This compressor will restart even

if the system has not equalized.

NOTE: Operang pressures and amp draws may dier from

standard reciprocang compressors. This informaon can be

found in the unit’s Technical Informaon Manual.

CAPACITY CONTROL - LEGACY MODELS

During the compression process, there are several pockets with-

in the scroll that are compressing gas. Modulaon is achieved

by venng a poron of the gas in the rst sucon pocket back to

the low side of the compressor thereby reducing the eecve

displacement of the compressor. See Figure A. Full capacity is

achieved by blocking these vents, increasing the displacement

to 100%. A solenoid in the compressor, controlled by an external

24-volt ac signal, moves the slider ring that covers and uncov-

ers these vents. The vent covers are arranged in such a manner

that the compressor operates somewhere around 67% capacity

when the solenoid is not energized and 100% capacity when

the solenoid is energized. The loading and unloading of the two

step scroll is done “on the y” without shung o the motor

between steps. See Figure B below. The unloaded mode default

was chosen for two reasons:

FIGURE B

1. It is expected that the majority of run hours will be in the

low capacity, unloaded mode.

2. It allows a simple two-stage thermostat to control capacity

through the second stage in both cooling and possibly heat-

ing if desired.

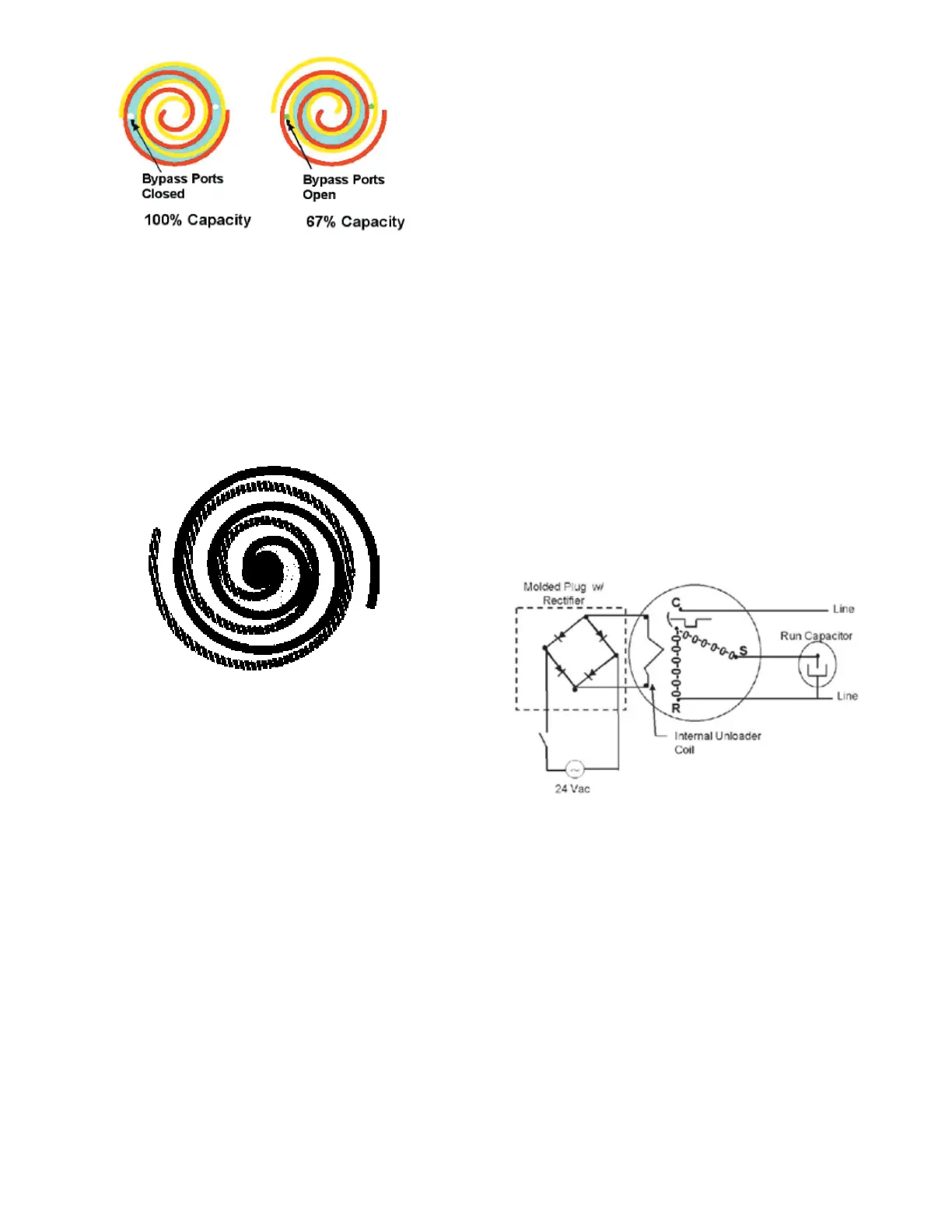

Unloader solenoid

A nominal 24-volt direct current coil acvates the internal

unloader solenoid. The input control circuit voltage must be 18

to 28 volt ac. The coil power requirement is 20 VA. The external

electrical connecon is made with a molded plug assembly. This

plug is connected to the Comfort Alert™ or CoreSense™ Module

(dependent upon which module you are using) which contains a

full wave recer to supply direct current to the unloader coil.

Loading...

Loading...