63

SERVICING

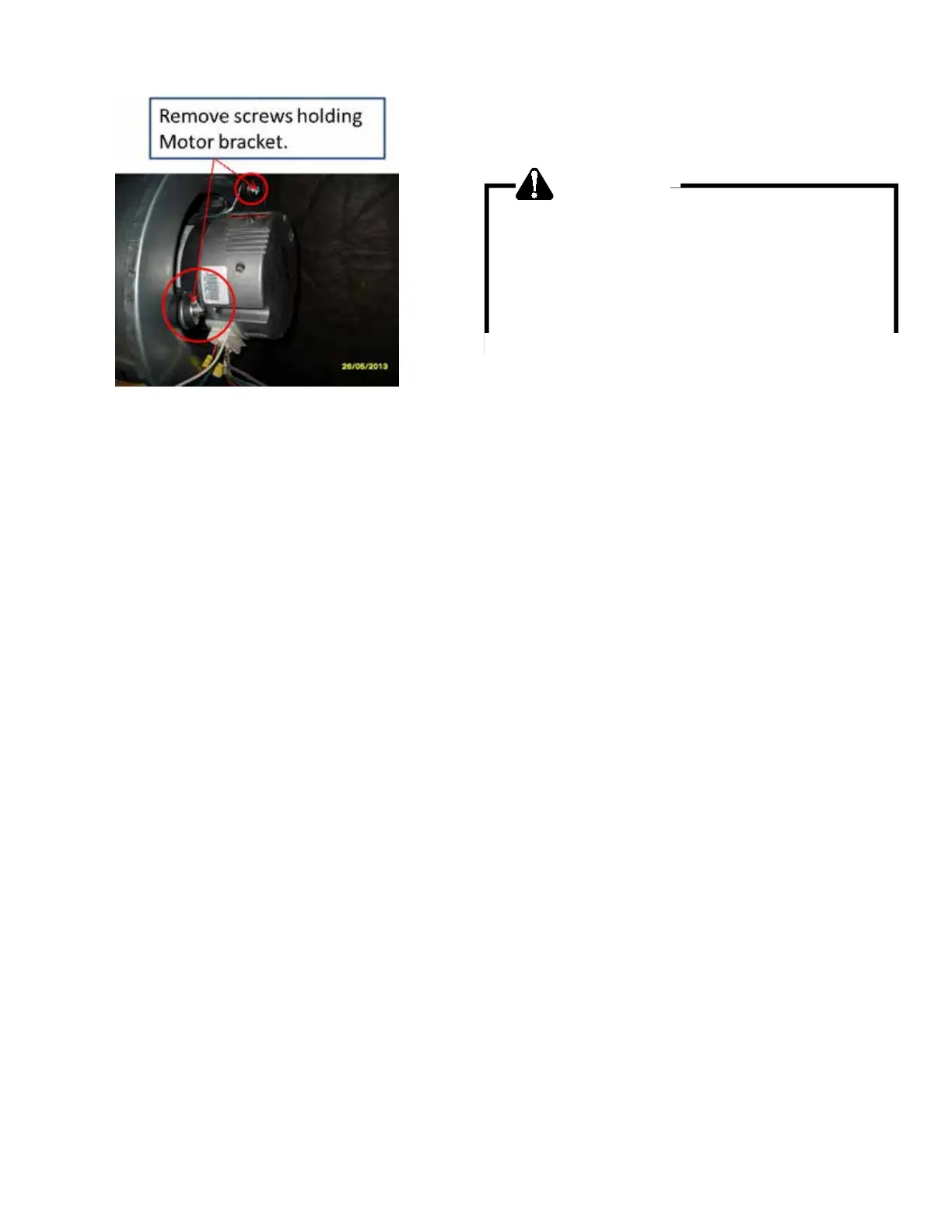

10. Remove the bolts holding the motor bracket to the

blower and slide out of blower shell.

11. Replace the motor and reinstall blower and control box.

12. Reconnect power and test operaon.

S-16C MBR/AR*F ELECTRONIC BLOWER TIME DELAY

RELAY

The MBR/AR*F contains an Electronic Blower Time Delay Relay

board, B1370735. This board provides on/o me delays for the

blower motor in cooling and heat pump heang demands when

“G” is energized.

During a cooling or heat pump heang demand, 24Vac is sup-

plied to terminal “G” of the EBTDR to turn on the blower motor.

The EBTDR iniates a 7 second delay on and then energizes it’s

onboard relay. The relay on the EBTDR board closes it’s normally

open contacts and supplies power to the blower motor. When

the “G” input is removed, the EBTDR iniates a 65 second delay

o. When the 65 seconds delay expires the onboard relay is

de-energized and it’s contacts open and remove power from the

blower motor.

During an electric heat only demand, “W1” is energized but “G”

is not. The blower motor is connected to the normally closed

contacts of the relay on the EBTDR board. The other side of this

set of contacts is connected to the heat sequencer on the heater

assembly that provides power to the rst heater element. When

“W1” is energized, the sequencer will close it’s contacts within

10 to 20 seconds to supply power to the rst heater element

and to the blower motor through the normally closed contacts

on the relay on the EBTDR. When the “W1” demand is removed,

the sequencer opens it contacts within 30 to 70 seconds and

removes power from the heater element and the blower motor.

The EBTDR also contains a speedup terminal to reduce the

delays during troubleshoong of the unit. When this terminal is

shorted to the common terminal, “C”, on the EBTDR board, the

delay ON me is reduced to 3 seconds and the delay OFF me is

reduced to 5 second.

Two addional terminals, M1 and M2, are on the EBTDR board.

These terminals are used to connect the unused leads from the

blower motor and have no aect on the board’s operaon.

s-17 CHECKING COMPRESSOR

WARNING

Hermetic compressor electrical terminal venting can

be dangerous. When insulating material which

supports a hermetic compressor or electrical terminal

suddenly disintegrates due to physical abuse or as a

result of an electrical short between the terminal and

the compressor housing, the terminal may be

expelled, venting the vapor and liquid contents of the

compressor housing and system.

If the compressor terminal PROTECTIVE COVER and gasket (if

required) are not properly in place and secured, there is a re-

mote possibility if a terminal vents, that the vaporous and liquid

discharge can be ignited, spoung ames several feet, causing

potenally severe or fatal injury to anyone in its path.

This discharge can be ignited external to the compressor if the

terminal cover is not properly in place and if the discharge im-

pinges on a sucient heat source.

Ignion of the discharge can also occur at the venng terminal

or inside the compressor, if there is sucient contaminant air

present in the system and an electrical arc occurs as the terminal

vents.

Ignion cannot occur at the venng terminal without the pres-

ence of contaminant air, and cannot occur externally from the

venng terminal without the presence of an external ignion

source.

Therefore, proper evacuaon of a hermec system is essenal

at the me of manufacture and during servicing.

To reduce the possibility of external ignion, all open ame,

electrical power, and other heat sources should be exnguished

or turned o prior to servicing a system.

S-17A RESISTANCE TEST

Each compressor is equipped with an internal overload.

The line break internal overload senses both motor amperage

and winding temperature. High motor temperature or amper-

age heats the disc causing it to open, breaking the common

circuit within the compressor on single phase units.

Heat generated within the compressor shell, usually due to recy-

cling of the motor, high amperage or insucient gas to cool the

motor, is slow to dissipate. Allow at least three to four hours for

it to cool and reset, then retest.

Fuse, circuit breaker, ground fault protecve device, etc. has not

tripped.

Loading...

Loading...