70

SERVICING

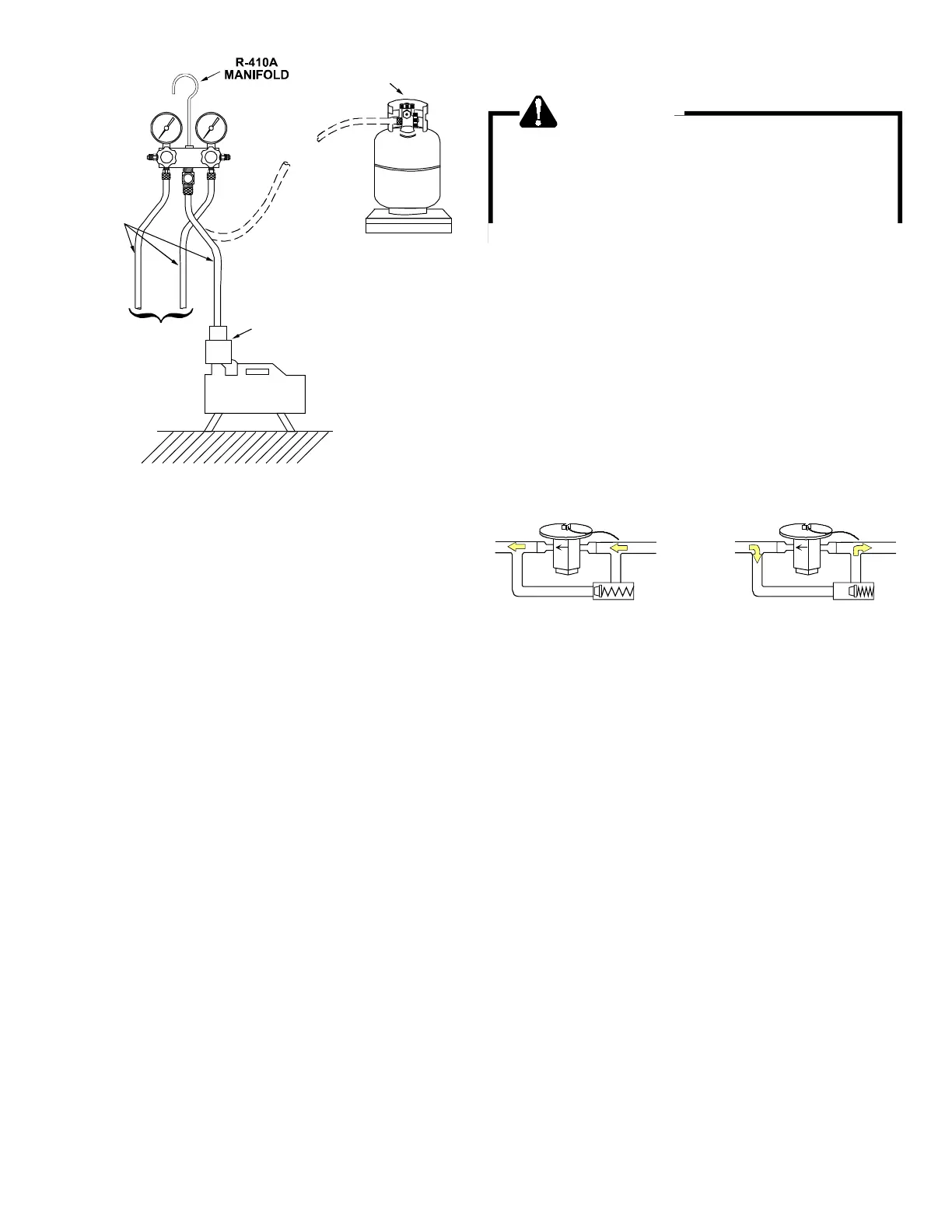

LOW SIDE

GAUGE

AND VALVE

HIGH SIDE

GAUGE

AND VALVE

TO

UNIT SERVICE

VALVE PORTS

VACUUM PUMP

VACUUM PUMP

ADAPTER

800 PSI

RATED

HOSES

CHARGING

CYLINDER

AND SCALE

EVACUATION

3. If the vacuum pump is working properly, close the valve to

the vacuum thermocouple gauge and open the high and low

side valves to the high vacuum manifold set. With the valve

on the charging cylinder closed, open the manifold valve to

the cylinder.

4. Evacuate the system to at least 29 inches gauge before open-

ing valve to thermocouple vacuum gauge.

5. Connue to evacuate to a maximum of 250 microns. Close

valve to vacuum pump and watch rate of rise. If vacuum

does not rise above 1500 microns in three to ve minutes,

system can be considered properly evacuated.

6. If thermocouple vacuum gauge connues to rise and levels

o at about 5000 microns, moisture and non-condensables

are sll present. If gauge connues to rise a leak is present.

Repair and re-evacuate.

7. Close valve to thermocouple vacuum gauge and vacuum

pump. Shut o pump and prepare to charge.

S-103 CHARGING

WARNING

REFRIGERANT UNDER PRESSURE!

* Do not overcharge system with refrigerant.

* Do not operate unit in a vacuum or at negative

pressure.

Failure to follow proper procedures may cause

property damage, personal injury or death.

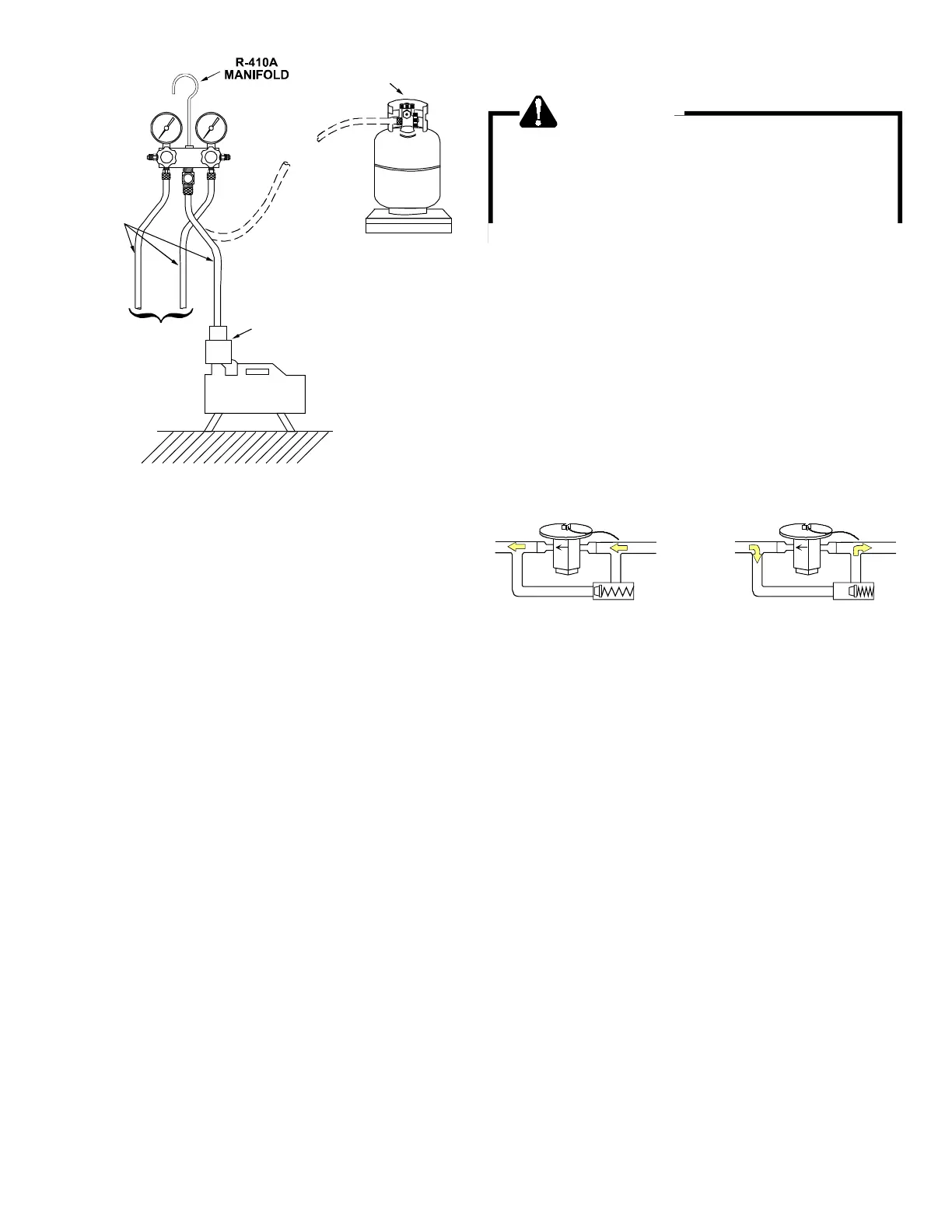

S-105B THERMOSTATIC EXPANSION VALVE

The expansion valve is designed to control the rate of liquid re-

frigerant ow into an evaporator coil in exact proporon to the

rate of evaporaon of the refrigerant in the coil. The amount of

refrigerant entering the coil is regulated since the valve responds

to temperature of the refrigerant gas leaving the coil (feeler

bulb contact) and the pressure of the refrigerant in the coil. This

regulaon of the ow prevents the return of liquid refrigerant to

the compressor.

The illustraon below shows typical heatpump TXV/check valve

operaon in the heang and cooling modes.

TXV VALVES

Some TXV valves contain an internal check valve thus eliminat-

ing the need for an external check valve and bypass loop. The

three forces which govern the operaon of the valve are: (1)

the pressure created in the power assembly by the feeler bulb,

(2) evaporator pressure, and (3) the equivalent pressure of the

superheat spring in the valve.

0% bleed type expansion valves are used on indoor and outdoor

coils. The 0% bleed valve will not allow the system pressures

(High and Low side) to equalize during the shut down period.

The valve will shut o completely at approximately 100 PSIG.

30% bleed valves used on some other models will connue to

allow some equalizaon even though the valve has shut-o com-

pletely because of the bleed holes within the valve. This type of

valve should not be used as a replacement for a 0% bleed valve,

due to the resulng drop in performance.

The bulb must be securely fastened with two straps to a clean

straight secon of the sucon line. Applicaon of the bulb to a

horizontal run of line is preferred. If a vercal installaon cannot

be avoided, the bulb must be mounted so that the capillary

tubing comes out at the top.

THE VALVES PROVIDED BY DAIKIN ARE DESIGNED TO MEET

THE SPECIFICATION REQUIREMENTS FOR OPTIMUM PRODUCT

OPERATION. DO NOT USE SUBSTITUTES.

Loading...

Loading...