12

On a call for 2nd stage cooling, the Y2 or Y2 and G thermo-

stat contacts close signaling the furnace control board with

24 VAC on Y2 or Y2 and G terminals.

• The 7-Segment will display the cool mode:

• The compressor and condenser fan are energized.

• The circulator fan is energized at cool speed after a

cool on delay. The electronic air cleaner will also be

energized.

• After the thermostat is satised, the compressor

is de-energized and the Cool Mode Fan O Delay

period begins.

• Following the Cool Mode Fan O Delay period, the

cool circulator and air cleaner relay are de-energized

To change the main blower speed in COOLING mode, follow

the following steps:

1. Press the left or right switch until LED displays “AC1

“(for single stage COOLING) or “AC2 “(for two-stage

COOLING). Press the center switch and LED will dis-

play the selected speed number as Fxx (xx: Blower

speed number from 1 to 9).

2. The control will rotate available speed number every

time left/right switches are pressed. All 9 speeds are

available for both Single and Two Stage cooling.

3. When the center switch is pressed, the current dis-

played speed will be selected, and control will apply

the newly selected speed in next cooling call.

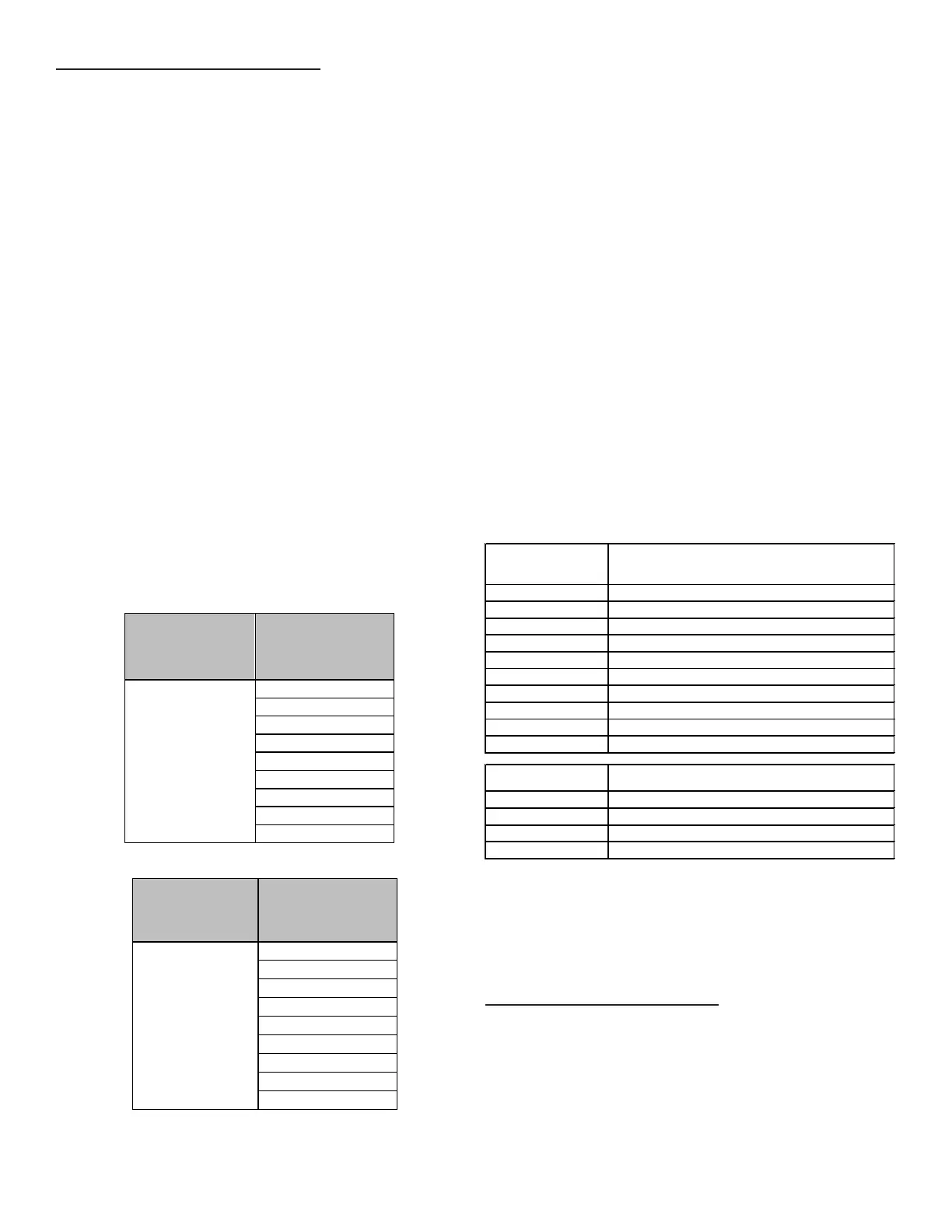

THERMOSTATCALL AVAILABLESPEEDS

Y/Y1

F01

F02

F03

F04(DEFAULT)

F05

F06

F07

F08

F09

THERMOSTATCALL AVAILABLESPEEDS

Y2

F01

F02

F03

F04

F05(DEFAULT)

F06

F07

F08

1. Set the thermostat to the lowest setting. The inte-

grated control will close the gas valve and extinguish

ame. Following a 15 second delay, the induced draft

blower will be de-energized. After the blower o delay

time expires, the blower de-energizes.

2. Remove the burner compartment door and move the

furnace gas valve manual control to the OFF position.

3. Close the manual gas shuto valve external to the

furnace.

4. Replace the burner compartment door.

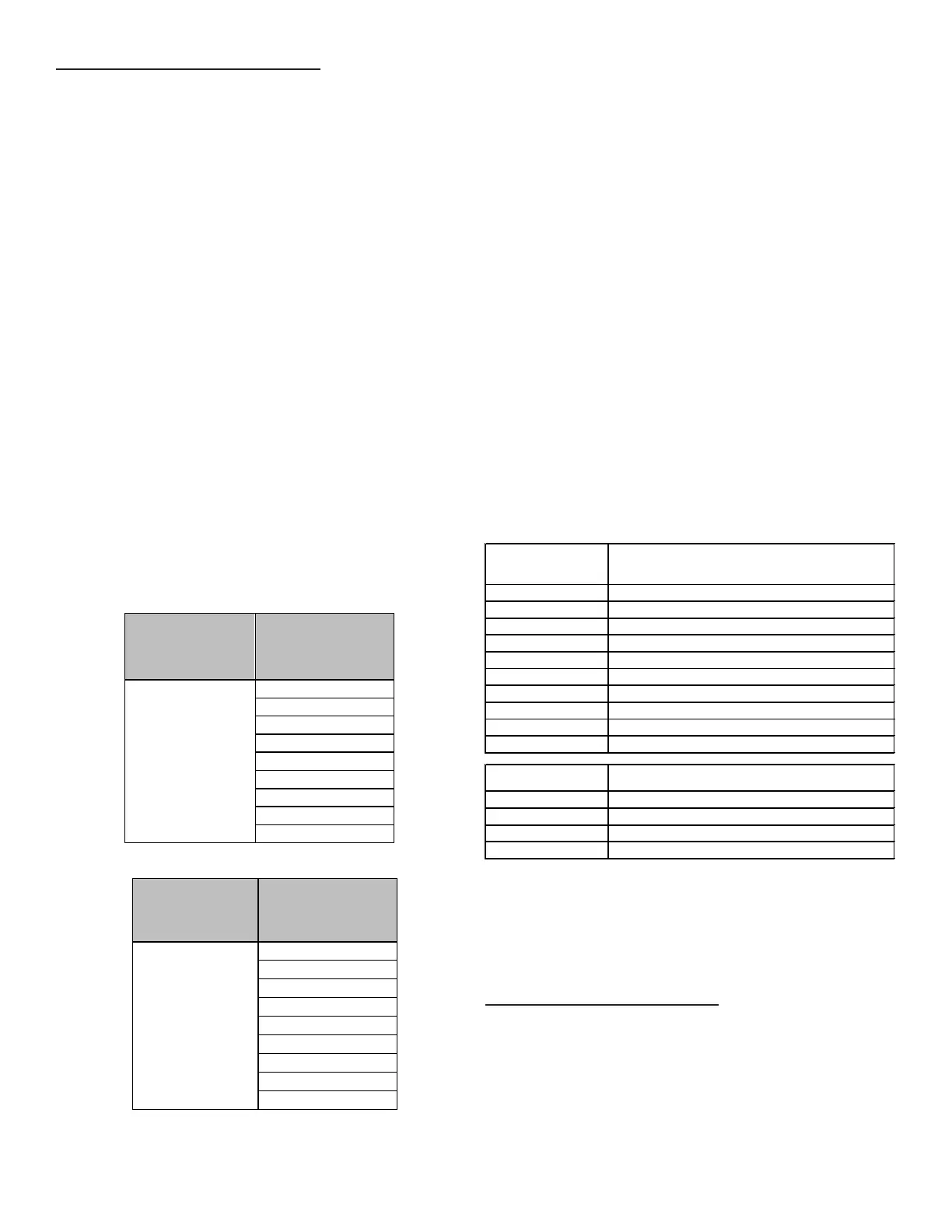

Filters must be used and well maintained. There are no pro-

visions to install lters inside the furnace cabinet. Refer to

the chart below for minimum lter sizes. A deep pleated lter

or electronic air lter may also be used.

DM80SN furnaces require installer provision of a return air

lter located on the side or bottom of the furnace or a cen-

trally located lter.

DC80SN furnaces require installer provision of a lter rack

located in the return air plenum or a centrally located lter

Upflow / Horizontal

Models

Minimum Recommended Filter Size^

*0403A* 1 - 16 X 25 Side or 1 - 14 X 24 Bottom Return

*0603A* 1 - 16 X 25 Side or 1 - 14 X 24 Bottom Return

*0604B* 1 - 16 X 25 Side or Bottom Return

*0803B* 1 - 16 X 25 Side or Bottom Return

*0804B* 1 - 16 X 25 Side or Bottom Return

*0805C*

1 - 16 X 25 Side or Bottom Return¹

*0805D* 2 - 16 X 25 Side or 1 - 20 X 25 Bottom Return

*1005C* 2 - 16 X 25 Side or 1 - 20 X 25 Bottom Return

*1205D* 2 - 16 X 25 Side or 1 - 24 X 24 Bottom Return

*1405D* 2 - 16 X 25 Side or 1 - 24 X 24 Bottom Return

Downflow Models Minimum Recommended Filter Size^

*0403A* 2 - 10 X 20 or 1 - 14 X 25 Top Return

*0603A* 2 - 10 X 20 or 1 - 14 X 25 Top Return

*0804B* 2 - 14 X 20 or 1 - 16 X 25 Top Return

*1005C* 2 - 14 X 20 or 1 - 20 X 25 Top Return

¹ = us e 2 - 16 X 25 fi l ters and two side returns or 20 X 25 filter on bottom

return if furnace is connected to a cooling unit over 4 tons nominal capacity

^ Filters may also be centrally located

The external lter rack kit is intended to provide a location

external to the furnace casing, for installation of a perma-

nent lter on upow model furnaces. The rack is designed

to mount over the indoor blower compartment area of either

side panel, and provide lter retention as well as a location

for attaching return air ductwork.

Loading...

Loading...