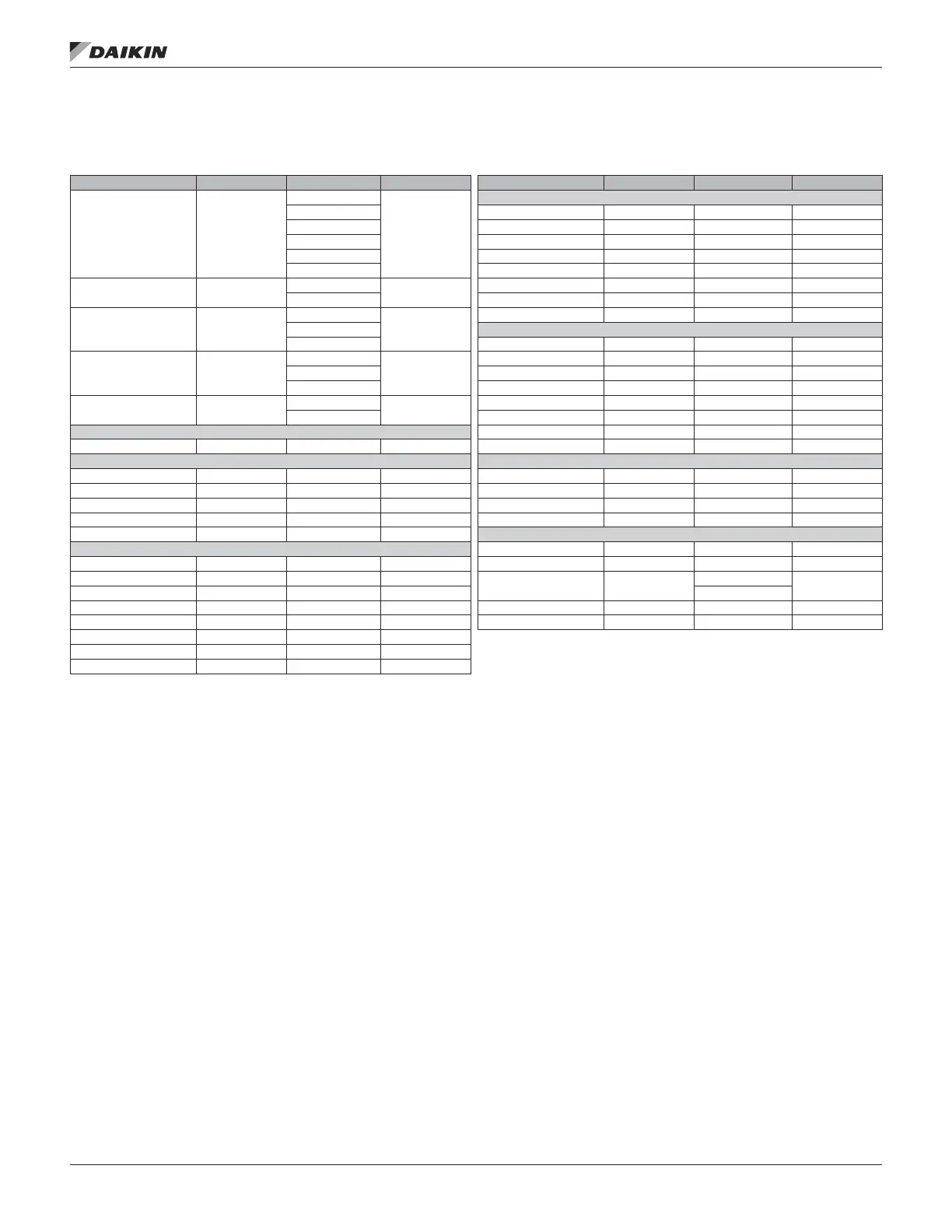

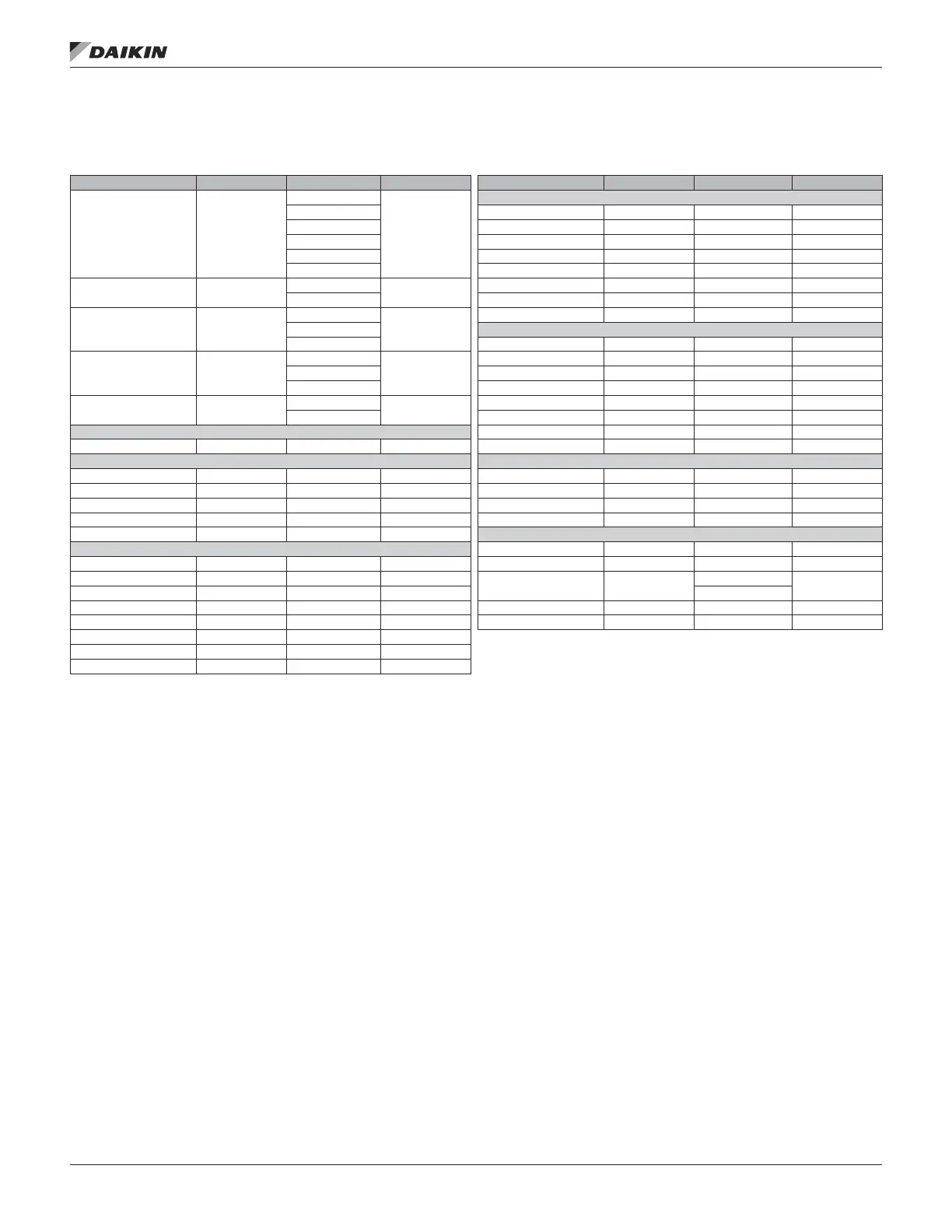

SAF Set-up

Table 21: Supply Fan Speed Menu

Item Display Name Default Setting Range Password Level

Item Display Name Default Setting Range Password Level

SAF Ctrl= DSP

DSP

4

CO

2

CONTROL

Spd/Net Min PPM= 0ppm 0–5000ppm 2

1ZnVAV Max PPM= 2000ppm 0–5000ppm 2

BSP V/A @ Min PPM= 0.0/V 0.0–20.0/V/mA 2

CO2 V/A @ Max PPM= 10.0/V 0.0–20.0/V/mA 2

CFM Min SAF PPM= 800 0–5000ppm 4

AplyInputChgs= No

No

2

Max SAF PPM= 1100 0–5000ppm 4

Yes Min PPM Spd= 50 0–100% 4

CO

2

Input= None

None

2

Max PPM Spd= 100 0–100% 4

VDC CFM CONTROL

MA Min CFM= 0CFM 0–60000CFM 2

CFM Input= None

None

2

Max CFM= 10000CFM 0–60000CFM 2

VDC V/A @Min CFM= 0.0/V 0.0–20.0/V/mA 2

MA V/A @Max CFM= 10.0/V 0.0–20.0/V/mA 2

BSP Input= No

No

2

SAF CFM DB= 3% 0–100% 4

Yes SAFCFM Period= 30s 0–999s 4

SPEED CONTROL SAF CFM Gain= 0.1 0.0–100.0 4

Rem SAF Cap= 33% 0–100% 4 SAF CFM MxChg= 5% 0–100% 4

DSP CONTROL BSP CONTROL

DSP DB= 0.1in 0–0.5in 4 BSP DB= 0.01in 0.0–0.1in 4

SAF Ramp Time= 60s 0–999s 4 BSP Period= 5s 0–999s 4

Min Period= 5s 0–999s 4 BSP Gain= 0.2 0.0–100.0s 4

Max Spd Chg= 15% 0–100% 4 Max Spd Chg= 4% 0–100% 4

DuctPress1= — 0.0–5.0in 2 SAF SETUP

1 ZONE VAV CONTROL SAF Ctrl Dly= 30s 0–999s 4

Min Clg Spd= 40% 0–100% 4 Min Speed= 33% 0–100% 4

Max Clg Spd= 100% 0–100% 4

VAVBox Out= —

Heat

2

Min Htg Spd= 40% 0–100% 4 Cool

Max Htg Spd= 100% 0–100% 4 MaxVentSpd= 100% 0–100% 2

Space Period= 60s 0–999s 4 Max SAF RPM= 2600 0–5000 2

Space Gain= 0.8 0.0–100.0s 4

Space PAT= 400s 0–999s 4

Space Max Chg= 10% 0–100% 4

SAF Ctrl is an adjustable parameter used to select how the

supply fan is to be controlled. The supply fan can normally be

controlled by duct pressure, space temperature (single zone

VAV or 1ZnVAV) or by a percentage of supply air fan speed

from 33% to 100%. On 100% OA unit applications the fan can

be controlled to maintain building static pressure, space carbon

dioxide level or and airow based on a eld supply airow

station. The speed option is typically used with a building

automation system. When single zone VAV control is selected,

the supply fan is controlled with a PI_Loop to maintain the

Control Temperature input at the Occupied Cooling Set Point or

Occupied Heating Set Point. When BSP is selected the supply

fan is controlled with a PI_Loop to maintain the building static

pressure at a building static pressure Set Point.

When CO

2

is selected the supply fan is controlled to maintain

the CO

2

ppm between adjustable limits by varying the supply

fan speed between an adjustable range. When CFM is

selected the supply fan is controlled with a PI_Loop to maintain

the measured CFM at a CFM set point.

AplyInputChgs is the Apply Input Changes ag must be

changed from no to yes in order for the controller to recognize

the changes. Setting the Apply Input Changes ag to YES will

automatically reset the controller.

CO

2

Input is an adjustable item used to select the type of

input for a eld installed CO

2

sensor. If this is set to None the

controller ignores any CO

2

sensor input. If CO

2

control and/

or monitoring is desired this parameter is set to VDC or mA

to match the input type of the eld supplied CO

2

sensor input.

This parameter applies only to 100% OA unit congurations.

CFM Input is an adjustable item used to select the type of

input for a eld installed airow station. If this is set to None the

controller ignores any eld airow station input. If CFM control

and/or monitoring is desired this parameter is set to VDC or mA

to match the input type of the eld supplied airow input. This

parameter applies only to 100% OA unit congurations.

Menu desCrIpTIons

www.DaikinApplied.com 35 OM 920-6 • MICROTECH UNIT CONTROLLER

Loading...

Loading...