3Installation

Installationmanual

6

AZQS100~140B8V1B+AZQS100~140B7Y1B

Splitsystemairconditioners

4P3855281–2014.08

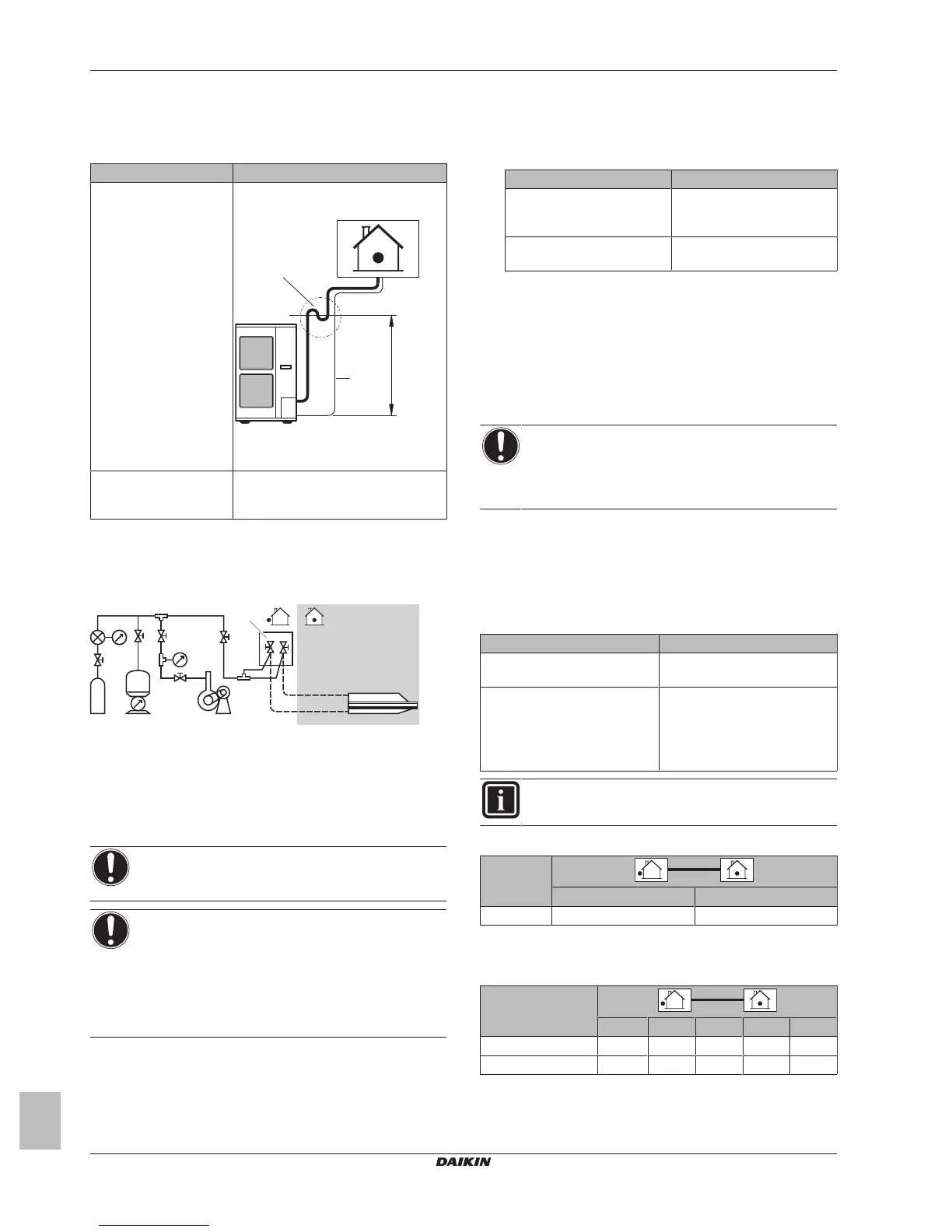

3.2.2 Todetermineifoiltrapsarerequired

Ifoilflowsbackintotheoutdoorunit'scompressor,thismightcause

liquidcompressionordeteriorationofoilreturn.Oiltrapsintherising

gaspipingcanpreventthis.

If Then

Theindoorunitisinstalled

higherthantheoutdoor

unit

Installanoiltrapevery10m(height

difference).

aRisinggaspipingwithoiltrap

bLiquidpiping

Theoutdoorunitis

installedhigherthanthe

indoorunit

OiltrapsareNOTrequired.

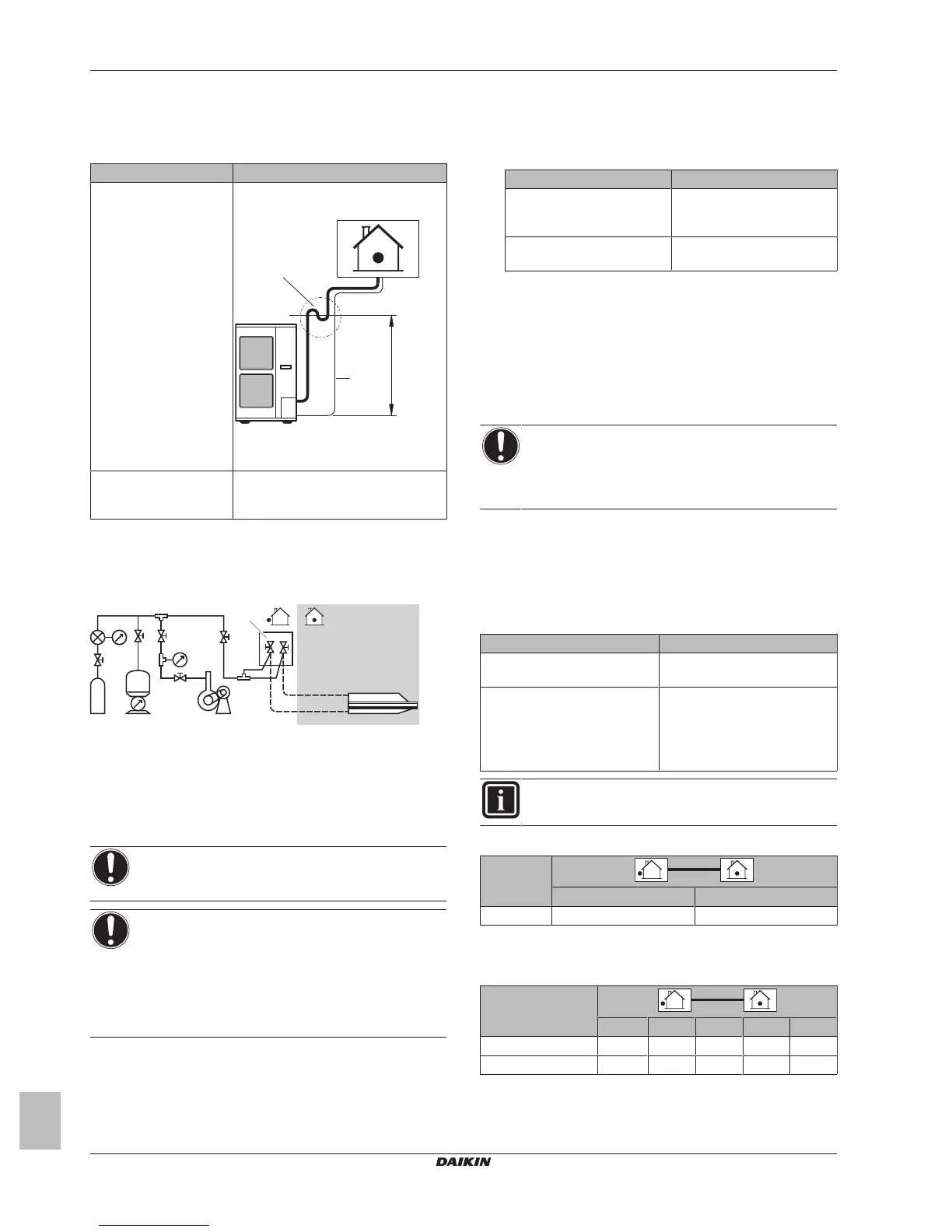

3.3 Checkingtherefrigerantpiping

3.3.1 Checkingrefrigerantpiping:Setup

a Pressuregauge

b Nitrogen

c Refrigerant

d Weighingmachine

e Vacuumpump

f Stopvalve

3.3.2 Tocheckforleaks

NOTICE

DoNOTexceedtheunit'smaximumworkingpressure(see

"PSHigh"ontheunitnameplate).

NOTICE

Make sure to use a recommended bubble test solution

from your wholesaler. Do not use soap water, which may

causecrackingofflarenuts(soapwatermaycontainsalt,

which absorbs moisture that will freeze when the piping

gets cold), and/or lead to corrosion of flared joints (soap

water may contain ammonia which causes a corrosive

effectbetweenthebrassflarenutandthecopperflare.

1 Chargethesystemwithnitrogengasuptoagaugepressureof

at least 200 kPa (2 bar). It is recommended to pressurize to

3000kPa(30bar)inordertodetectsmallleaks.

2 Check for leaks by applying the bubble test solution to all

connections.

3 Dischargeallnitrogengas.

3.3.3 Toperformvacuumdrying

1 Vacuumthesystemuntilthepressureonthemanifoldindicates

−0.1MPa(−1bar).

2 Leaveasisfor45minutesandcheckthepressure:

Ifthepressure… Then…

Doesnotchange Thereisnomoistureinthe

system.Thisprocedureis

finished.

Increases Thereismoistureinthe

system.Gotothenextstep.

3 Evacuateforat least 2 hours to a pressure on the manifold of

−0.1MPa(−1bar).

4 After turning OFF the pump, check the pressure for at least

1hour.

5 IfyoudoNOTreachthetargetvacuumorcannotmaintainthe

vacuumfor1hour,dothefollowing:

▪ Checkforleaksagain.

▪ Performvacuumdryingagain.

NOTICE

Make sure to open the stop valves after installing the

refrigerantpipingandperformingvacuum drying. Running

the system with the stop valves closed may break the

compressor.

3.4 Chargingrefrigerant

3.4.1 Todeterminetheadditionalrefrigerant

amount

Todetermineifaddingadditionalrefrigerantisnecessary

If Then

L1≤30m(chargelesslength) Youdonothavetoadd

additionalrefrigerant.

L1>30m Youmustaddadditional

refrigerant.

Forfutureservicing,encirclethe

selectedamountinthetables

below.

INFORMATION

Pipinglengthistheonewaylengthofliquidpiping.

Todeterminetheadditionalrefrigerantamount(Rinkg)

30~40m 40~50m

R: 0.5kg 1.0kg

3.4.2 Todeterminethecompleterecharge

amount

Model

5~10 10~20 20~30 30~40 40~50

AZQS100+125 1.9 2.4 2.9 3.4 3.9

AZQS140 3.0 3.5 4.0 4.5 5.0

Loading...

Loading...