Si39-303 Refrigerant Piping

Installation Manual 169

Caution Be sure to use the attached pipe when carrying out piping work in the field.

Be sure that the local piping does not touch other pipes, the bottom panel or side panel.

Especially for the bottom and side connection, be sure to protect the local piping with the

provided insulation, to prevent it from coming into contact with the casing.

Precautions when knocking out knock holes

!

Be sure to avoid damaging the casing

!

After knocking out the holes, we recommend you paint the edges and areas around the

edges using the repair paint to prevent rusting.

!

When passing electrical wiring through the knock holes, wrap the wiring with protective tape

to prevent damage.

!

Open knock holes around the 4 concave knock holes in the base frame, using a

φ

6mm-bit

drill.

2. Make sure to perform the piping installation within the range of the maximum allowable pipe

length, allowable level difference and allowable length after branching as indicated in

chapter “Example of connection”

3. For installation of the refrigerant branching kit, refer to the installation manual delivered with

the kit.

Mount the REFNET joint so that it branches either horizontally or vertically.

Mount the REFNET header so that it branches horizontally.

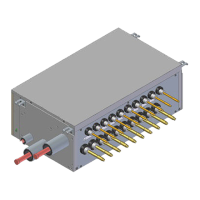

4. Pipe connection

•

Only use the flare nuts included with the unit.

Using different flare nuts may cause the refrigerant to leak.

•

Be sure to perform a nitrogen blow when brazing.

(Brazing without performing nitrogen replacement or releasing nitrogen into the piping will

create large quantities of oxidized film on the inside of the pipes, adversely affecting

valves and compressors in the refrigerating system and preventing normal operation.)

•

Do not use a flux when brazing the refrigerant pipe joints.

Use phosphor copper brazing (BCup) which does not require flux.

(Using a chlorine flux may cause the pipes to corrode, and if it contains fluoride it may

cause the refrigerant lubricant to deteriorate, adversely affecting the refrigerant piping

system.)

Notes:

!

The pressure regulator for the nitrogen released when doing the brazing should be set to

0.02 MPa(0.2kg/cm

2

) or less.

1.Refrigerant piping

2.Location to be brazed

3.Nitrogen

4.Taping

5.Manual valve

6.Regulator

7.Nitrogen

Knock hole

Drill

Concave section

A

1

A-arrow diagram

2

1. Horizontal wires

2. Up to ±30× or vertically.

B

3

B-arrow diagram

3. Horizontal wires

1

2

4

5

6

3

7

Loading...

Loading...