Installation Si39-303

24 General Information

Flare Connection

(a) Stiffened pipe must always be annealed at least once prior to the flaring work.

(b) A pipe cutter must be used to cut the pipe. (A large pipe cutter must be used where the pipe has a large

diameter. When cutting a pipe which is too big for the pipe cutter a metal saw may be used but care

must be taken to ensure that the debris from sawing does not get into the pipe.)

(c) Set the flaring tool to make sure the flare size remains within the prescribed limits.

New Rank Compatible Flare Tool

Compared to previous refrigerants, the components of a HFC refrigerant is small. R410A also has a higher

pressure than other refrigerants. Therefore, in order to strengthen the intensity of the form and size of the

flare section used for R410A (class 2) apparatus, unlike the specification of the conventional refrigerants, it

was set up with different standards.

When carrying out flare processing, use a new rank compatible flare tool or a conventional flare tool.

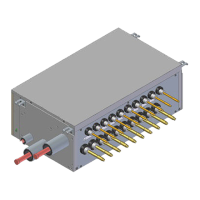

Flare Gauge (Adapter Corresponding to the New Rank)

When using the later, use a flare gauge to take out the pipe from the gauge bar, adjust it, and then carry out

the flare processing.

Size from the dice surface to the copper tip (in mm)

(d) Coat the inner and outer surface of the flare with refrigerator oil (Ester or ether oil). (this ensures that the

flare nut passes smoothly, preventing the pipe from twisting.)

Do not use SUNISO-4GS oil.

Important points

1. Burrs should be carefully removed.

2. 2 spanners should be used to grip the flare nuts.

3. The flare nut must be inserted before starting the flaring operation.

4. The appropriate amount of torque should be used to tighten the flare nut.

5. Check that there is no superficial damage to the surface of the flare.

Nominal diameter External diameter of pipe d Pipe widening dimensions A

1/4 6.35 9.1

3/8 9.52 13.2

1/2 12.7 16.6

5/8 15.88 19.7

3/4 19.05 24.0

Name

Outer

diameter

Wall

thickness

Previous refrigerant (R22, R407C etc.) R410A

The conventional flare tool The conventional flare tool

Clutch type Clutch type

1/4 6.35 0.8 0~0.5 1.0~1.5

3/8 9.52 0.8 0~0.5 1.0~1.5

1/2 12.70 0.8 0~0.5 1.0~1.5

5/8 15.88 1.0 0~0.5 1.0~1.5

Standard torques for tightening flare nut

±

10%

Size

Torque

(kgf-cm) (N-cm)

1/4(6.4

φ

) 144~176 1420~1720

3/8(9.5

φ

) 333~407 3270~3990

1/2(12.7

φ

) 504~616 4950~6030

5/8(15.9

φ

) 630~770 6180~7540

3/4(19.1

φ

) 990~1210 9270~11860

12mm×72mm

1.0×0.5mm Each

Flare gauge

Size

Thickness

Loading...

Loading...