4 Preparation

Installation manual

11

RWEQ96~432TAYCU

VRV W T-Series water-cooled system air conditioner

4P540122-1B – 2018.11

4.3 Refrigerant pipe size and allowable

length

NOTE

The refrigerant R410A requires strict cautions for keeping

the system clean, dry and tight.

▪ Cleananddry:foreignmaterials(includingmineraloils

or moisture) should be prevented from getting mixed

into the system.

▪ Tight: R410A does notcontain any chlorine, does not

destroy the ozone layer, and does not reduce earth’s

protection against harmful ultraviolet radiation. R410A

can contribute slightly to the greenhouse effect if it is

released. Therefore we should take special attention to

check the tightness of the installation.

4.3.1 Selection of piping material

NOTE

Piping and other pressure containing parts shall comply

with the applicable legislation and shall be suitable for

refrigerant. Use phosphoric acid deoxidized seamless

copper for refrigerant.

NOTE

▪ All field piping must be installed by a licensed

refrigeration technician and must comply with relevant

local and national regulations.

▪ After piping work is complete, do not under any

circumstances open the stop valve until

"5.8 Connecting the electrical wiring" on page 30.

"6 Checking of device and installation conditions" on

page 34 are complete.

▪

Do not use flux when brazing the refrigerant piping. Use

the phosphor copper brazing filler metal

(B-Cu93P-710/795 : ISO 3677) which does not require

flux. Flux has extremely negative effect on refrigerant

piping systems. For instance, if the chlorine based flux is

used, it will cause pipe corrosion or, in particular, if the

flux contains fluorine, it will damage the refrigerant oil.

▪ Useonly pipeswhicharecleaninsideandoutside andwhich do

not accumulate harmful sulfur, oxidants, dirt, cutting oils, moisture,

or other contamination. (Foreign materials inside pipes including

oils for fabrication must be 0.14 gr/10 ft (30 mg/10 m) or less.)

▪ Usethefollowingitemsfortherefrigerantpiping.

Material : Jointless phosphor-deoxidized copper pipe.

Size : See "4.3.2 To select the piping size".

Thickness : Select a thickness for the refrigerant piping which

complies with national and local laws.

▪ Forpipingwork,followthemaximumtoleratedlength,differencein

height, and length after a branch indicated in the "4.3.7 Piping

length requirements" on page 15.

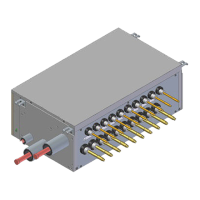

▪ Outsideunit multiconnection pipingkitand refrigerantbranch kit

(sold separately) are needed for connection of piping between

outside units (in case of multi system) and piping branches.

▪ Use only separately sold items selected specifically according to

the outside unit multi connection piping kit, the refrigerant branch

kit selection in the "4.3.3 To select refrigerant branch kits" on page

12.

4.3.2 To select the piping size

INFORMATION

Please select the proper pipe sizes depending on the

mode of your system. There are 2 possible modes:

▪ heatpump,

▪ heatrecovery.

Determine the proper size using the following tables and reference

figure (only for indication).

In case of heat pump mode

A

B B B

C

D F

G

E

x

y

b

a

1 2

3 4

b

1,2,3,4 VRV indoor unit

a,b Indoor branch kit

x,y Outside multi connection kit

In case of heat recovery mode

A

B B B

C

D E

E

x

y

b

a

4

3

1 2

1,2 VRV indoor unit

3 Branch selector unit

4 Cooling only VRV indoor unit

A~E Piping

a,b Indoor branch kit

x,y Outside multi connection kit

A, B, C: Piping between outside unit and (first)

refrigerant branch kit

Choose from the following table in accordance with the outside unit

total capacity type, connected downstream.

In case of heat pump mode

Unit: inch (mm)

Outside unit

capacity type (MBH)

Piping outer diameter size

Gas pipe Liquid pipe

96 7/8 (22.2) 3/8 (9.5)

120, 144 1-1/8 (28.6) 1/2 (12.7)

192, 216 5/8 (15.9)

240 1-3/8 (34.9)

264~336 3/4 (19.1)

360~432 1-5/8 (41.3)

Loading...

Loading...