4 Preparation

Installation manual

16

RWEQ96~432TAYCU

VRV W T-Series water-cooled system air conditioner

4P540122-1B – 2018.11

Cooling water

(b)

and

circulation system

Hot water system

(c)

Tendency

(d)

Item

(a)

Circulation

water

Make-up

water

Circulation

water

(68~140°F)

(20~60°C)

Make-up

water

Corrosion Scale

Ionic-state silica (mg SiO

2

/l) <50 <30 <30 ○

Reference items

Iron (mg Fe/l) <1.0 <0.3 <1.0 <0.3 ○ ○

Copper (mg Cu/l) <0.3 <0.1 <1.0 <0.1 ○

Sulfate ion (mg S

2–

/l) — ○

Ammonium ion (mg NH

4

+

/l) <1.0 <0.1 <0.3 <0.1 ○

Residual chlorine (mg Cl/l) <0.3 <0.25 <0.3 ○

Free carbon dioxide (mg CO

2

/l) <4.0 <0.4 <4.0 ○

Stability index 6.0~7.0 — — ○ ○

(a) These items represent typical causes of corrosion and scale.

(b) In a condenser water circuit that uses a closed cooling tower, the closed circuit circulating water and make-up water MUST meet the water quality

standards for the hot water system, and passing water and make-up water MUST satisfy those for the circulation type cooling water system.

(c) Corrosion has a tendency to occur when water temperature is high (104°F (40°C) or higher), and if metals with no protective coating are directly

exposed to water, it would be a good idea to take effective measures against corrosion such as adding a corrosion inhibitor or deaeration

treatment.

(d) The circle marks in the columns indicate a tendency for corrosion or scale to develop.

NOTE

▪ Thesupply water MUSTbeclean tapwater,industrial

water or clean underground water. Do NOT use purified

or softened water.

▪ Do NOT use once-through water. It may cause

corrosion.

4.4.2 Water circuit requirements

INFORMATION

Also read the precautions and requirements in the

"General safety precautions" chapter.

NOTE

Use water pipes compiled with the local and national codes.

▪ Thewaterpressureresistanceofwaterpipingofthisoutsideunit

is 464 psig (3.2 MPa).

▪ The connection port for water piping is located in the front. The

connection ports for drain piping are located in the front and back.

When using the back port, change the cast iron plug from the back

to the front and securely close it.

▪ Inindooruse,pipingworkshouldbesuchthatnowaterdropson

the outer plate.

▪ Thelateral protruding sectionofthe drainpipingshould be short

(within 15-3/4 inch (400 mm)) and installed in a downward

direction.

The diameter of drain pipe should be the same as the diameter of

unit connection (3/8 inch (9.5 mm)) or more.

▪ Thediameterofwaterpipeshouldbethesameasthediameterof

unit connection (1-1/4 inch (31.8 mm)) or more.

▪ Install an air purge valve in the midway of the water piping to

prevent cavitation.

▪ Aftercompleting the drainpipingwork, make surethat the water

runs smoothly without any clogging by dust.

▪ Donotconnectthedrainoutlettothewateroutlet.

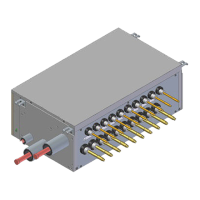

▪ Installa strainer (standardaccessory)in theinletof water piping

within a distance of 4.9 ft (1.5 m) from the outside unit.

(If sand, waste or rust particles are mixed in the water circulation

system, metal materials will become corrosive.)

▪ Install insulation on the inlet/outlet of water piping to prevent

condensation and freezing.

At installing insulation on water in/outlet pipe, use Polyurethane

foam thickness 3/16 inch (5 mm) for insulation of water piping

socket on heat exchanger.

▪ Installinsulationuptothebaseofheatexchangerasshowninthe

figure 6.

▪ Install a gate valve for chemical cleaning in an easy position to

handle.

▪ Usewaterpipescompliantwiththelocalandnationalcodes.

▪ Runthewaterpumptoflushinsideofwaterpiping.

Then, clean the strainer.

▪ If there is a possibility of freezing, take measures to prevent

freezing.

▪ Connectwaterpipingandheatexchangerviapipeadaptor

(accessory)(ISO228-1•G1-1/4B→ANSI-ASMEB1.20.1•

1-1/4-11.5NPT)

▪ Tighten securely the connection of water piping and socket with

tightening torque of 220 ft·lbf (300 N·m) or less.

(If a large torque is applied, the unit may be damaged.)

Example:

≥

3.15 inch

(80 mm)

b

m g

d

e

e

a

j

n

k

c

l

i

f h

a Air purge (field supply)

b Water outlet

c Water inlet

d Shut-off valve (field supply)

e Water connection

f Water piping (field supply)

g Insulation (field supply)

h Pipe adaptor (accessory)

i Heat exchanger

j Strainer (accessory)

k Drain valve (field supply)

l Drain connection

m Insulation cover

n Flow switch (field supply)

Loading...

Loading...