4 Preparation

Installation manual

18

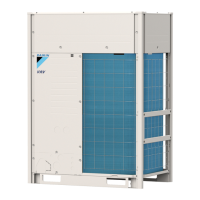

RWEQ96~432TAYCU

VRV W T-Series water-cooled system air conditioner

4P540122-1B – 2018.11

The valve/pump input signal is based on a variable 2~9 V DC control

output signal coming from the outside unit. The valve or pump

should have a linear control characteristic between unit output signal

and flow rate according to the example graph below.

0%

B

E

D

C

c

A

50%

100%

2 V DC 9 V DC

a Valve/pump flow rate

b Unit/system flow rate

c Valve/pump input signal

A Maximum required flow rate (100%)

B 50% of the maximum required flow rate

C Minimum flow rate (see description below)

D Maximum flow rate (see description below)

E Hydronic flow rate

Follow the design criteria below to select the correct valve for the

system. The valve system maximum required flow rate A is a

property of the supplied valve and the 50% flow rate B is directly

related to the maximum flow rate of the system.

INFORMATION

Some third party valves/pumps have a maximum flow rate

defined by the hardware of the system, but a different

maximum flow rate can be set to correspond with the

maximum input voltage (9 V DC) The installer should ask

information to the valve/pump supplier before making the

selection.

Design criteria

1 Minimum flow rate C:

Model C

RWEQ96~144 13.2 gpm (50 l/min)

21.2 gpm (80 l/min)

(a)

(a) For antifreeze use

2 Maximum flow rate D:

Model D

RWEQ96~144 39.6 gpm (150 l/min)

3 Hydronic flow rate E:

The value E is the design flow rate calculated by the hydronic

engineer when designing the building system.

Correct valve selection is done when following conditions are met:

(B≥C) AND (E≤A≤D)

For further selection requirements, refer to "4.5 Field wiring" on

page 18.

Check the minimum flow rate of the system during commissioning to

ensure good operation.

During the initialization process of the outside unit, the output signal

will trigger a flow rate of B (50%). The installer should make sure

that a flow rate can be checked in the individual hydronic system of

each unit. If this value is not matching the required flow, the installer

should troubleshoot the hydronic system to solve the problem and

ensure the correct flow rate.

4.5 Field wiring

4.5.1 Safety device requirements

The power supply must be protected with the required safety

devices, i.e. a main switch, a slow blow fuse on each phase and/or a

circuit breaker.

Selection and sizing of the wiring should be done in accordance with

the applicable legislation based on the information mentioned in the

table below.

Model Minimum circuit

ampacity

Recommended

fuses

RWEQ96TAYCU 13.0 A 15 A

RWEQ120TAYCU 16.3 A 20 A

RWEQ144TAYCU 19.9 A 25 A

RWEQ192TAYCU 13.0+13.0 A 15+15 A

RWEQ216TAYCU 13.0+16.3 A 15+20 A

RWEQ240TAYCU 16.3+16.3 A 20+20 A

RWEQ264TAYCU 16.3+19.9 A 20+25 A

RWEQ288TAYCU 19.9+19.9 A 25+25 A

RWEQ312TAYCU 13.0+13.0+16.3 A 15+15+20 A

RWEQ336TAYCU 13.0+16.3+16.3 A 15+20+20 A

RWEQ360TAYCU 16.3+16.3+16.3 A 20+20+20 A

RWEQ384TAYCU 16.3+16.3+19.9 A 20+20+25 A

RWEQ408TAYCU 16.3+19.9+19.9 A 20+25+25 A

RWEQ432TAYCU 19.9+19.9+19.9 A 25+25+25 A

▪ Phaseandfrequency:3~60Hz

▪ Voltage:575V(RWEQ96~432TAYCU)

▪ Transmission line section insulated: AWG 18~16, maximum

length is 3280 ft (1000 m). If the total transmission wiring exceeds

these limits, it may result in communication error.

NOTE

When using residual current operated circuit breakers, be

sure to use a high-speed type 300 mA rated residual

operating current.

Loading...

Loading...