3.

240 VAC is Getting to the Heating

Elements, but Still No Heat.

a.

Check for continuity through the heating elements. If

no continuity, replace the heating element with the

included spare or order a replacement from Dairy

Tech, Inc.

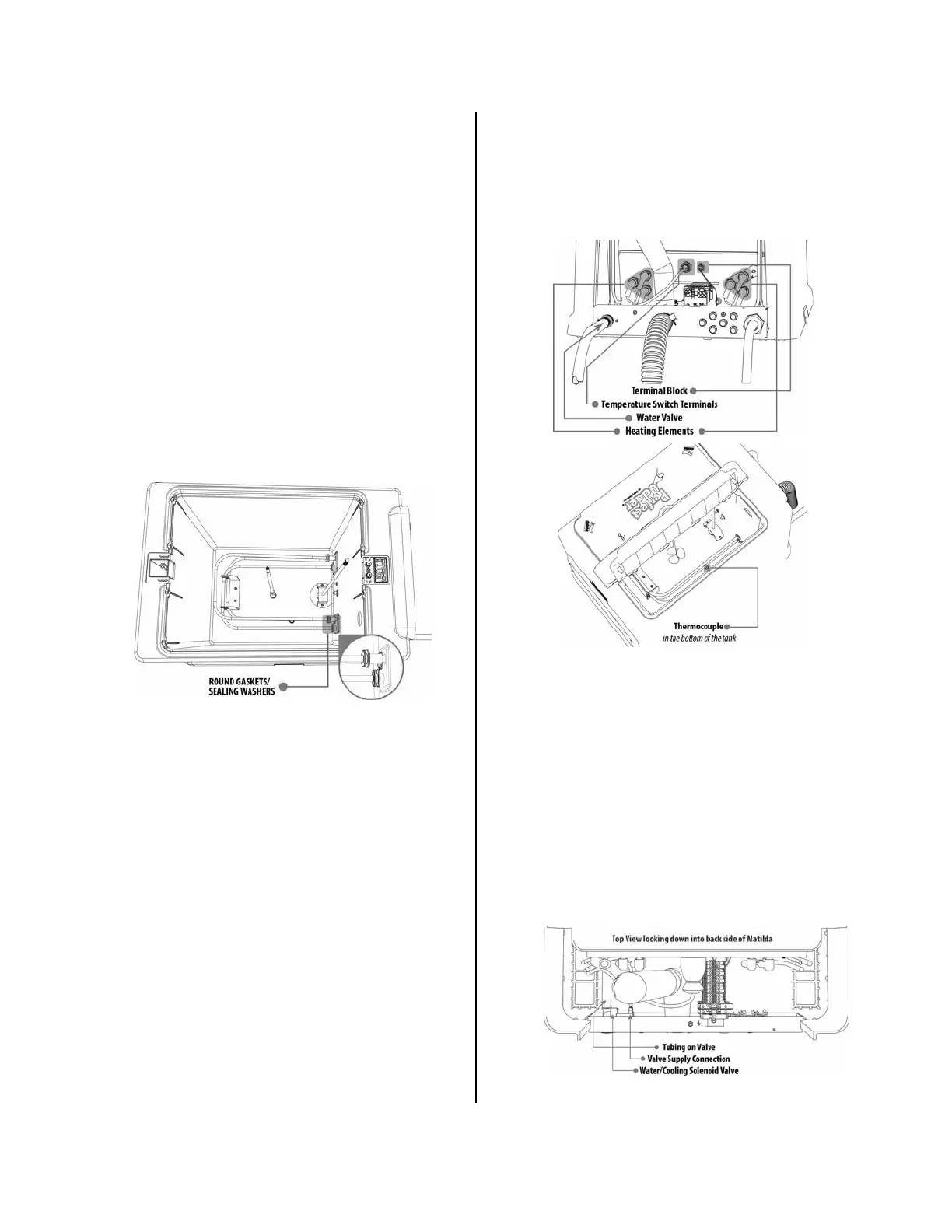

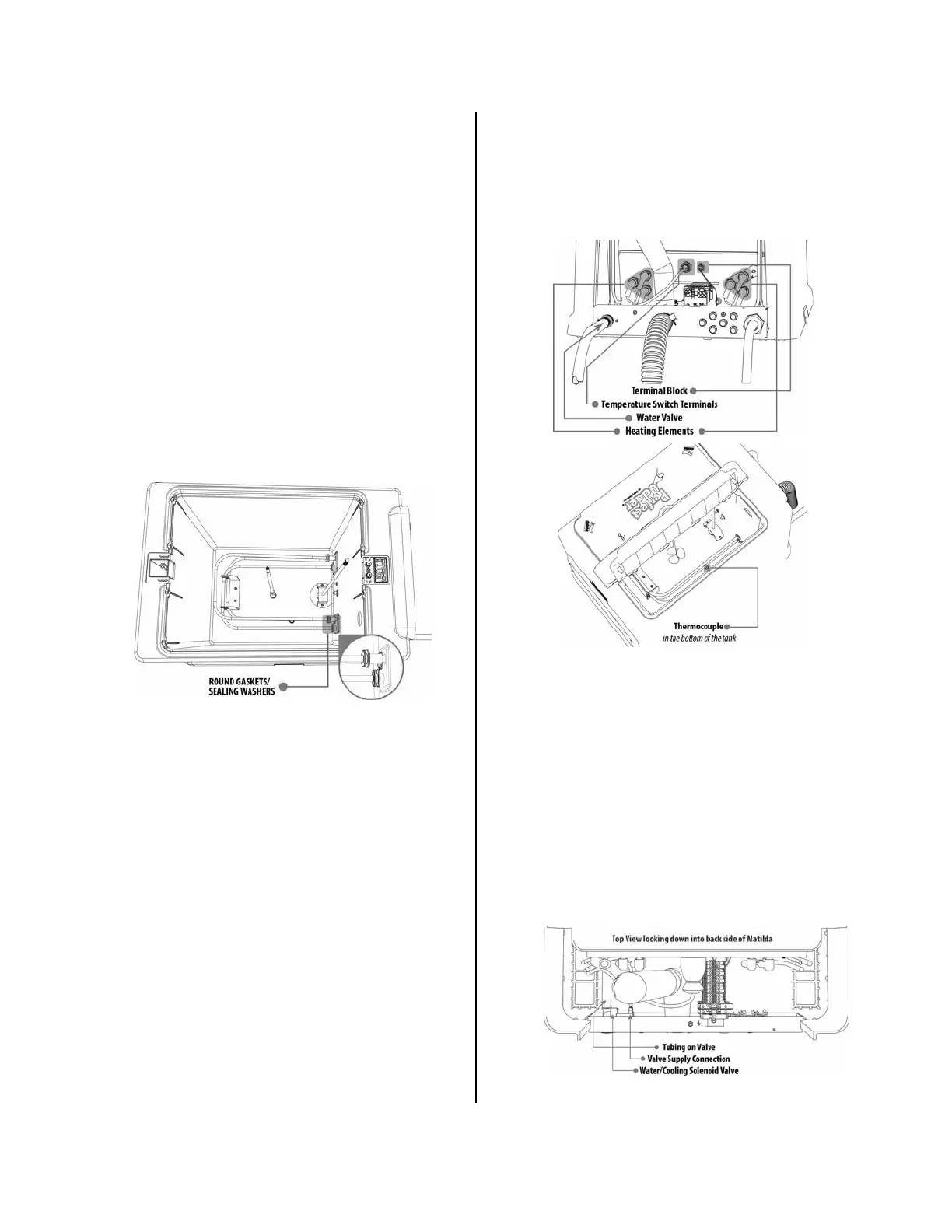

HEATING ELEMENTS: The heating elements are

replaced when necessary by removing the back panel

after disconnecting all power to the unit. Drain the

tank of water. Pull the terminal boots back from the

heater terminals and disconnect the ring terminals.

Loosen the 2 nuts that attach each heating element to

be removed. The elements must be removed in order

from top to bottom. Use caution when removing to

avoid dropping or striking the heaters against each

other. Remove the top heater by sliding it forward

into the tank and lifting it out of the unit. The middle

and bottom heaters may then be removed as needed.

Replace the element in the opposite order of their

removal. DO NOT OVER-TIGHTEN THE HEATER

ELEMENTS. Make sure all 6 round gaskets are in place

against the inside surface of the tank.

4.

Matilda® Does Not Get to Temperature, but

the Heater is Hot or Heats Slowly.

a.

There are two (2) or three (3) active heating elements

in each unit depending on the model. Check

resistance on each element with the power off to

determine if one needs replacing.

b.

Make certain that the agitator motor is turning during

the cycle. It should be on during heating, timing, and

cooling cycles. Replace if it is not working.

c.

Cold water is coming into the system. If there is a leak

in the system, such as a leaking cold-water solenoid

valve, the heater cannot keep up and the colostrum

will not heat properly. Repair the leak or replace the

valve.

5.

Water is Leaking from Under the Unit

a.

With power disconnected from the unit, open the

back panel and check the heating elements, over-

temperature switch, thermocouple, and water valve

for leaks. Also check the thermocouple in the bottom

of the tank and for damage to the tank itself.

6.

Cooling Solenoid Valve Will Not Stop

Running

a.

Check the power supply to the valve. IF there is power

keeping it open during unwanted times, the control

could be malfunctioning, especially if the cold output

LED # is on at the wrong times. Replace Control.

b.

It is possible that some debris has held the solenoid

open. Disconnect power and remove tubing from

valve inside cabinet. Blow into the supply hose to

eject any debris from the valve or force water

backward through the valve. The valve may need to

be replaced if it is powering properly but not closing

when the solenoid closes.

Loading...

Loading...