Reference displacement oset temperature

The thermostat setpoint and the alarm values get shifted by this value when the reference displacement is activated. Activa-

tion can take place via digital input.

Pull-down duration

Maximum duration of the pull-down mode. When set as “0” Pull down mode disabled.

Pull-down limit temperature

A safety feature; the lowest temperature allowed during pull-down.

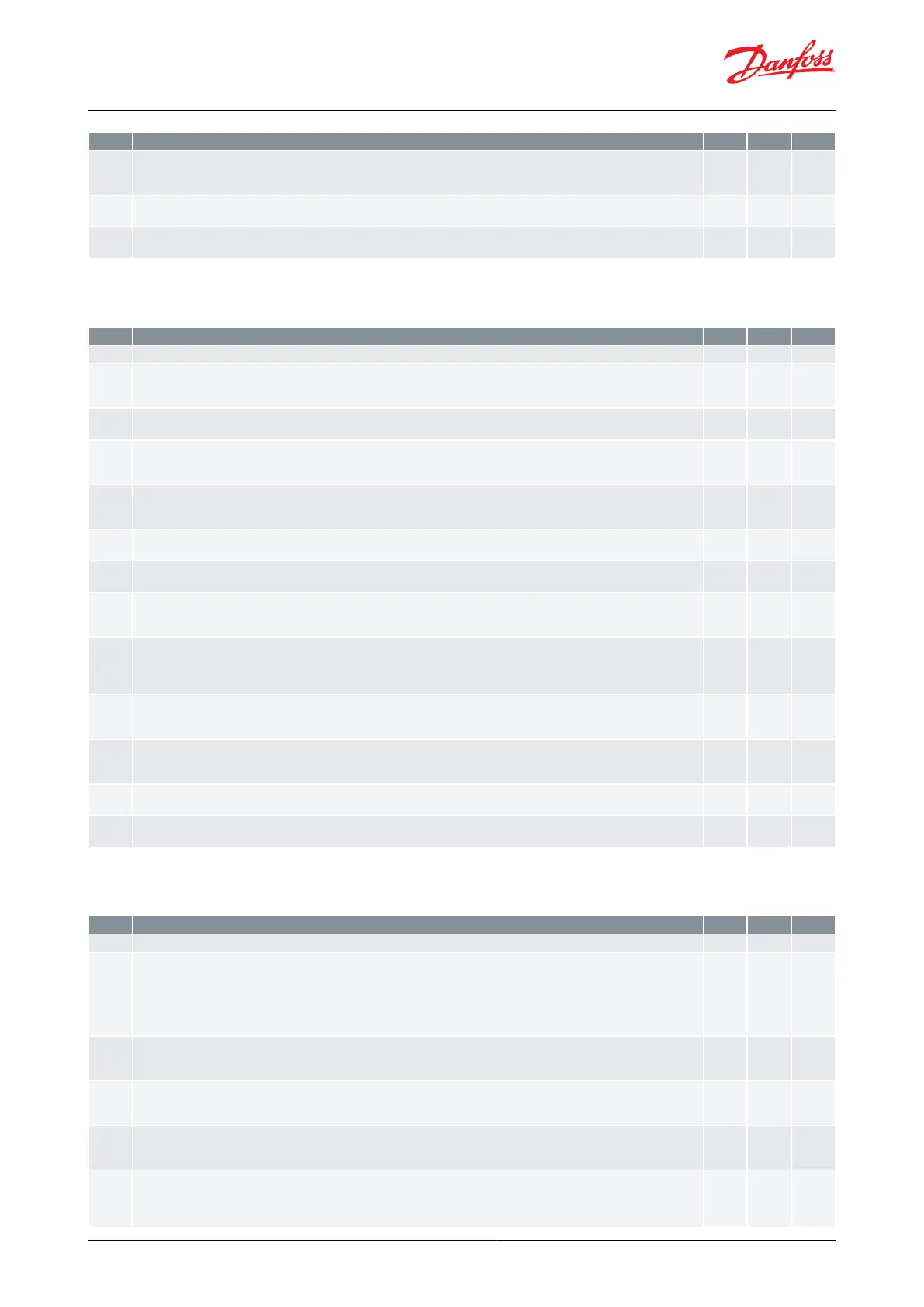

Alarm settings

Table 9: Alarm settings

Delay for temperature alarm during normal conditions

High and low temperature alarm will be delayed by this value after crossing the set alarm limits. The alarm will not become

active until the set time delay has been passed.

Delay for temperature alarm during pull-down/start-up/defrost

Controller uses this time delay to trigger low and high temperature alarms during start-up, defrost and pull-down modes

High temperature alarm limit

If the cabinet temperature stays above this limit for the time mentioned by the alarm delay parameters, high temperature

alarm is raised.

Low temperature alarm limit

If the cabinet temperature stays below this limit for the time mentioned by the alarm delay parameters, low temperature

alarm is raised.

DI1 delay

If Di1 is congured as a door open alarm or as an external alarm, this delay is used to raise the respective alarm.

DI2 delay

If Di2 is congured as a door open alarm or as an external alarm, this delay is used to raise the respective alarm.

Condenser high alarm limit

If the condenser temperature reaches above this limit, condenser alarm is raised immediately and no action is taken. The

alarm is reset if temperature falls 5 K below the set temperature.

Condenser High block limit

If the condenser temperature continues to increase above the A37 limit and reaches this temperature limit, condenser block

alarm is raised and compressor is stopped. It is restricted to starting again until alarm is reset manually. Manual reset of con-

denser block alarm can be performed by power cycling the controller either by main switch button or input supply.

Voltage protection

This parameter is to enable and disable the voltage protection feature, which protects compressor from adverse line voltage

conditions.

Minimum cut-in voltage

When the compressor is due to start, the voltage of the power supply will be checked and the compressor is allowed to start

if the supply voltage is greater than this value.

Minimum cut-out voltage

When the compressor is running, it will be switched OFF if the supply voltage goes below this value.

Maximum voltage

When the compressor is running, it will be switched OFF if the supply voltage exceeds this value.

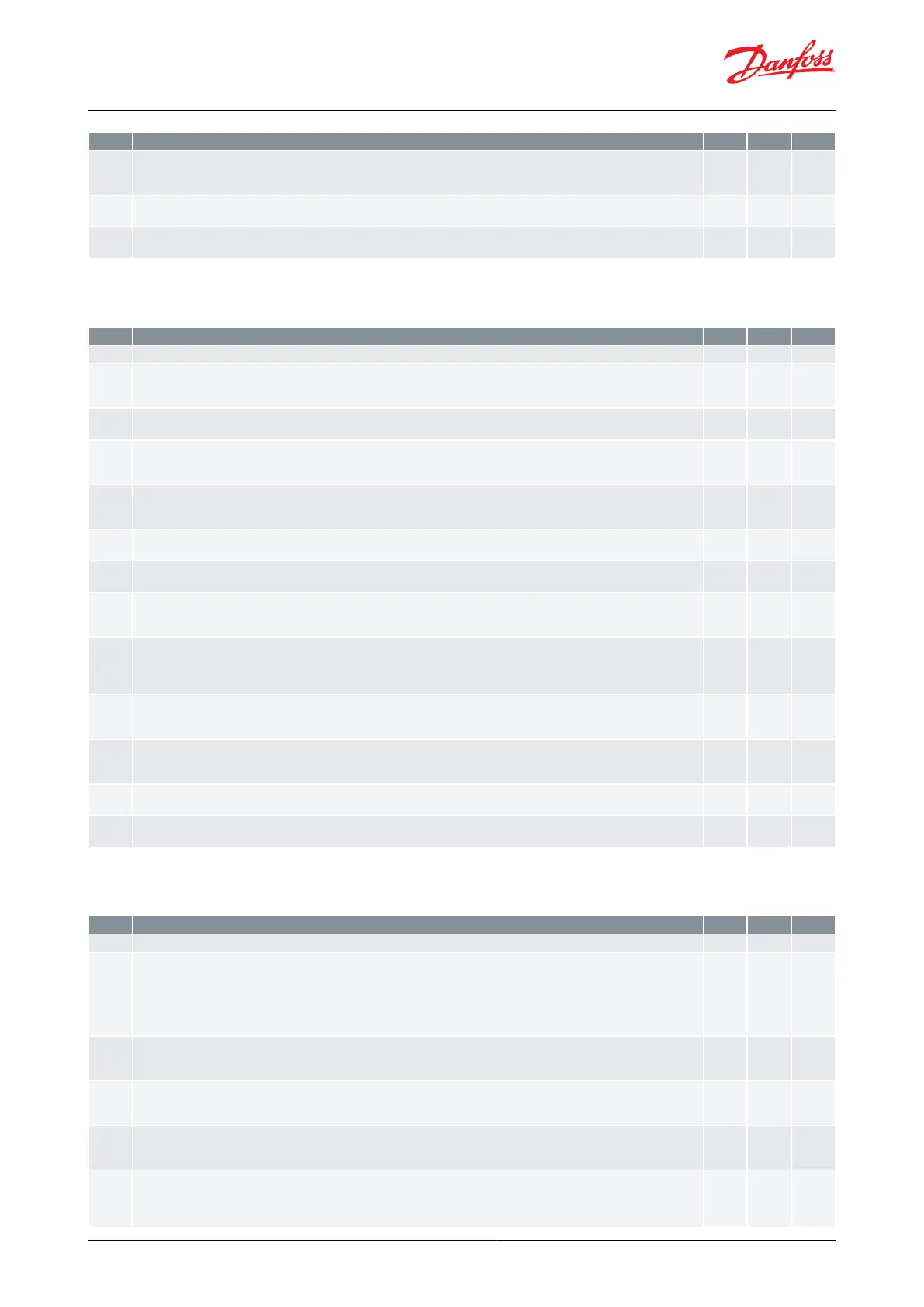

Defrost

Table 10: Defrost

Defrost type

Selection of desired defrost type

no= No defrost (defrost function diabled)

nAt = Natural defrost (O cycle defrost)

EL = Electrical defrost

gAS = Hot gas defrost

Defrost stop temperature

This parameter denes at what temperature the defrost cycle will stop. Defrost can be stoped based on either evaporator

sensor or by the cabinet temperature sensor as dened in menu code d10.

Defrost interval

Denes the maximum time period between the start of two defrost cycles. In case of power failure elapsed time is stored in

the memory and next defrost will happen considering the stored time interval.

Maximum defrost time

This parameter denes the maximum time defrost will be performed. In case of temperature based defrost this is treated as

safety time to stop the defrost if it is not terminated based on the temperature.

Defrost delay at power up or DI signal

This parameter decides the time oset when the defrost is triggered by digital inputs or during power up. This function is

only relevant if you have several refrigeration appliances or groups where you want the defrost to be staggered in relation to

one another.

© Danfoss | Climate Solutions | 2023.01 BC194286421698en-000901 | 19

Electronic refrigeration control, type ERC 21X

Loading...

Loading...