User Guide | Intelligent Purging System (IPS 8) for Ammonia - Technical data, installation and use

© Danfoss | DCS (ms) | 2020.01

BC306932151284en-000201 | 19

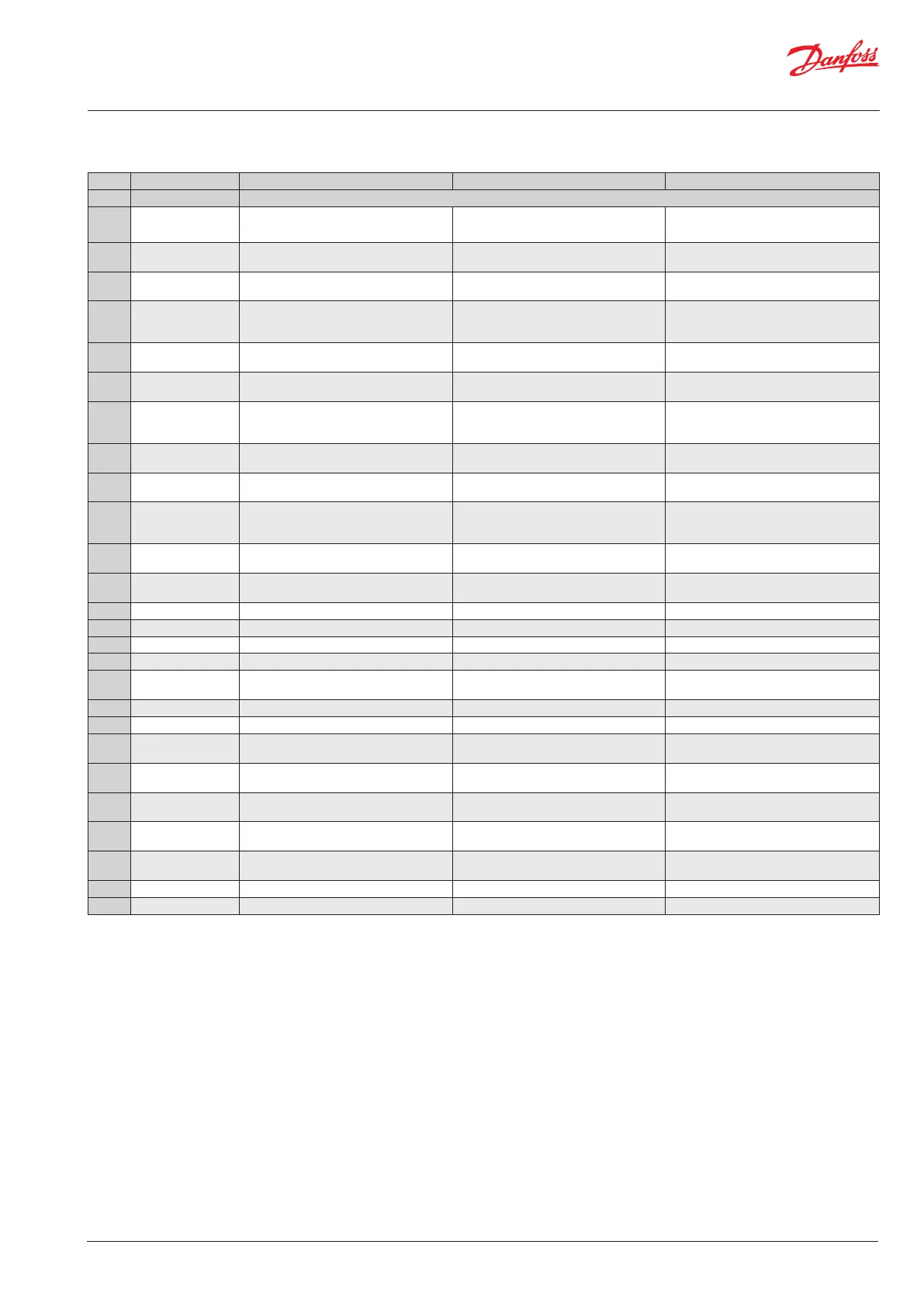

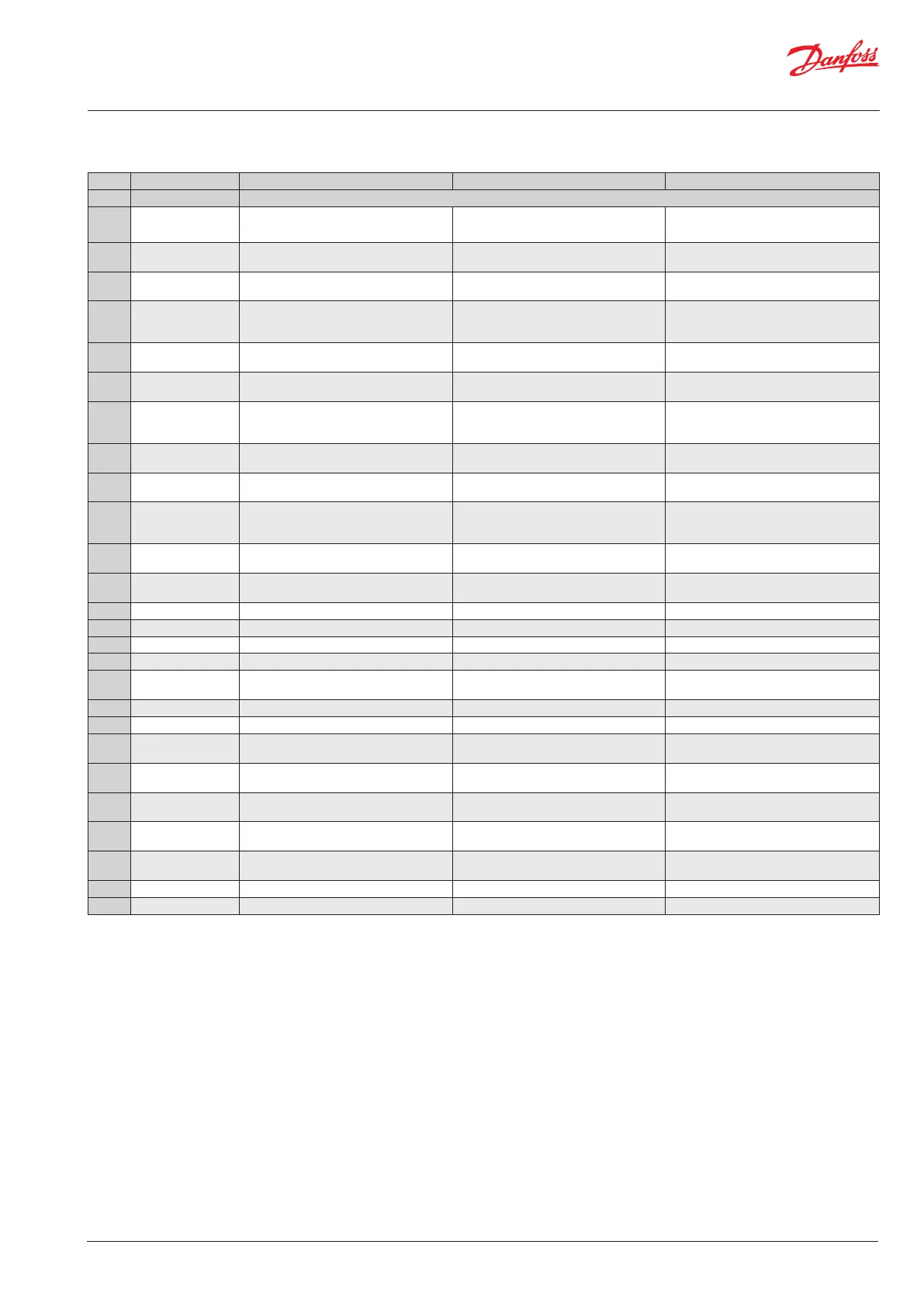

Label Parameter Name Description Possible Reason Recommended action

ALARMS

A01 General alarm Input from AI3 Leads to shut down of IPS 8 Fault in system connected to the DIO4 Input from AI3 Leads to shut down of IPS 9

E01 Temp Sensor Fault

Indicates no signal from temperature sensor

(R452a)

Broken wire to R452a temperature sensor

Repair temperature sensor wire or replace

temperature sensor

E01 Temp Sensor Fault

Indicates no signal from temperature sensor

(R452a)

Electrical supply failure supplying R452a

temperature sensor

Repair or replace power source

E01 Temp Sensor Fault

Indicates no signal from temperature sensor

(R452a)

Temperature measurement of the R452a line

is out of range

Compare temperature with another

temperature sensor reading and replace

temperature sensor if needed

E02 BPL Sensor Fault

Indicates no signal from pressure transmitter

(R452a)

Broken wire to R452A pressure transmitter

Repair pressure transmitter wire or replace

pressure transmitter

E02 BPL Sensor Fault

Indicates no signal from pressure transmitter

(R452a)

Electrical supply failure to the R422a pressure

transmitter

Repair or replace power source

E02 BPL Sensor Fault

Indicates no signal from pressure transmitter

(R452a)

Pressure measurement of the R452a line is out

of range

Compare pressure with another pressure

reading and replace pressure transmitter if

needed

E03 BPL Sensor Fault

Indicates no signal from pressure transmitter

(R717)

Broken wire to R717 pressure transmitter

Repair pressure transmitter wire or replace

pressure transmitter

E03 BPL Sensor Fault

Indicates no signal from pressure transmitter

(R717)

Electrical supply failure to the R717 pressure

transmitter

Repair or replace power source

E03 BPL Sensor Fault

Indicates no signal from pressure transmitter

(R717)

Pressure measurement of the R717 line is out

of range

Compare pressure with another pressure

reading and replace pressure transmitter if

needed

E04 Low temperature

Indicates too low ambient temperature

(<-10 °C)

Too low ambient temperature Move the IPS to a higher ambient temperature

E05 High temperature

Indicates too high ambient temperature

(>120 °C)

Too high ambient temperature Move the IPS to a lower ambient temperature

E05 High temperature Low R452a charge because of possible leak Locate and repair leak Evacuate Move the IPS to a lower ambient temperature

E06 Low pressure BPL Indicates too low R717 pressure Closed stop valve Open inlet stop valve

E07 High pressure BPL Indicates too high R717 pressure Ammonia system pressure too high Wait for lower pressure

E08 Low pressure BPH Indicates too low R452a pressure Low R452A charge

Find and repair leak, evacuate and recharge

with R452a

E09 High pressure BPH Indicates too high R452a pressure R452s system pressure too high Wait for lower pressure

E10 System is OFF Indicates status of the main switch Main switch is OFF Switch ON the main switch

E11 Memory is full A memory reset is required Memory is full from long time operation

Clean MCX memory by means of finding

Parameters_UnitConfig_

E12 Totla purge time error

This occurs when PLT is activated System will

automatically restart when CST has expired

Restrictor is blocked Replace the restrictor

E13 Compressor ERROR

Indicates no status is being received from

relay KL01

Possible broken wire from the MCX Repair broken wire from the MCX

E14 Liquid alarm

Signal from the LLS that there is liquid in the

evaporator

E15 Memory wrong!

Wrong counter values The unit will

automatically repair itself

E16 Discharge sensor error Indicates no signal from temperature sensor

E17 Suction sensor error Indicates no signal from temperature sensor

Table 03

Occurring active alarms, possible reasons and recommended action

All alarms except (*) activates red light on box outside

For alarms not resettable and/or cause not identified, please contact Danfoss

Level legend: 0 = Read view, 2 = Installer view (code 200) 3 = Danfoss Service view (Contact Danfoss)

Loading...

Loading...