User Guide | Intelligent Purging System (IPS 8) for Ammonia - Technical data, installation and use

24 | BC344024774466en-000201

© Danfoss | DCS (ms) | 2021.03

13

14

15

16

17

18

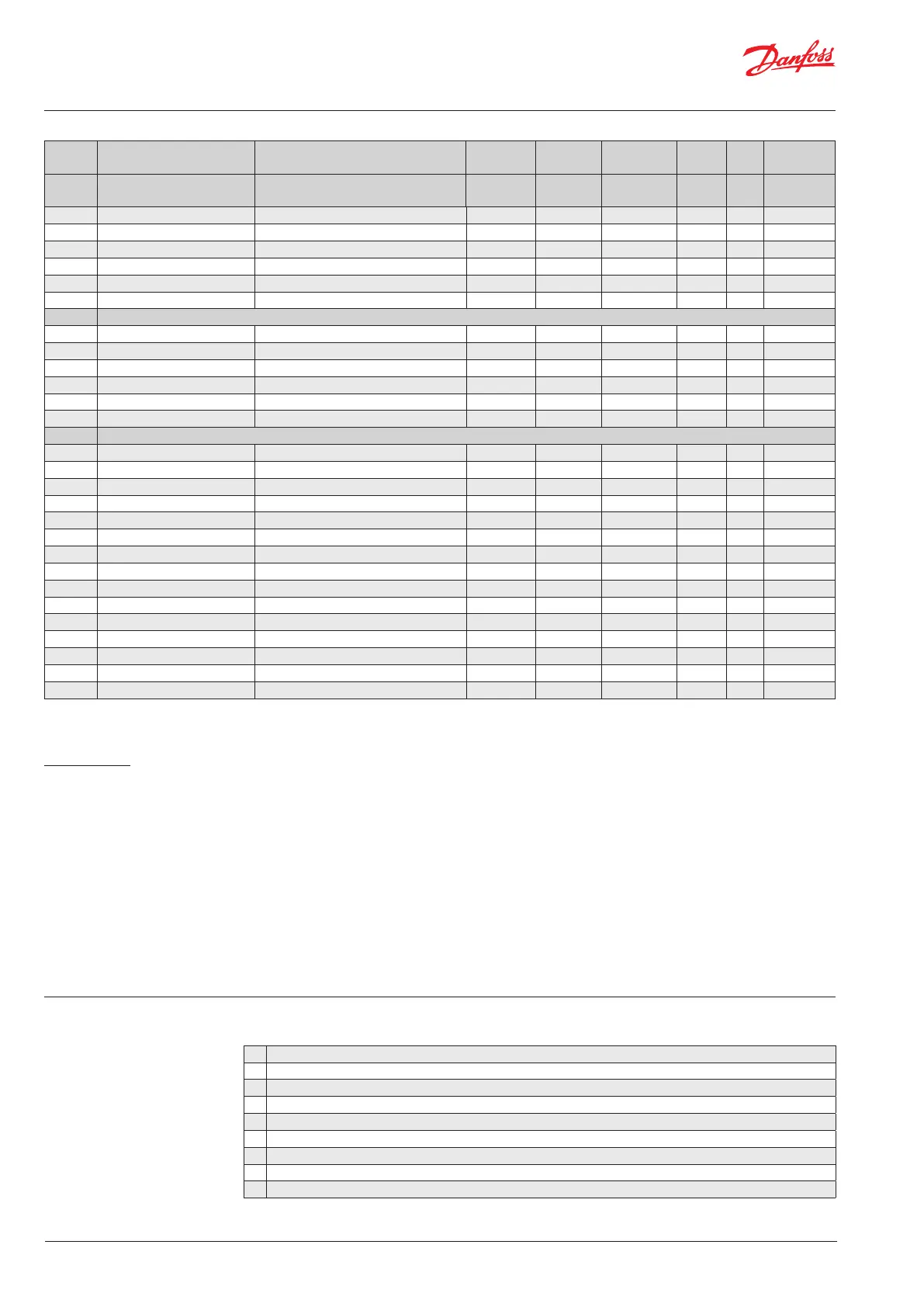

AO ANALOG OUTPUTS

1

2

3

4

5

6

DO DIGITAL OUTPUTS

1 Compressor Compressor relay 0 1 N.O. Read 18007

2 Valve Main purge valve relay 0 1 N.O. Read 18008

3 Green Status LED 0 1 N.O. Read 18004

4 Yellow Status LED 0 1 N.O. Read 18005

5 DO_Red Status LED 0 1 N.O. Read 18006

6 ICFD_Valve ICFD relay (solenoid valve) 0 1 N.O. Read 18017

7 Valve1 Purge point valve relay 0 1 N.O. Read 18009

8 Valve2 Purge point valve relay 0 1 N.O. Read 18010

9 Valve3 Purge point valve relay 0 1 N.O. Read 18011

10 Valve4 Purge point valve relay 0 1 N.O. Read 18012

11 Valve5 Purge point valve relay 0 1 N.O. Read 18013

12 Valve6 Purge point valve relay 0 1 N.O. Read 18014

13 Valve7 Purge point valve relay 0 1 N.O. Read 18015

14 Valve8 Purge point valve relay 0 1 N.O. Read 18016

15 Alarm IPS general alarm output 0 1 N.O. Read 18002

Label ID Parameter name Description and selection options MIN MAX VALUE/TYPE UNIT RW

Modbus

address

PARAMETERS & STATUS

VARIABLES

Modbus RTU

Good Practice

The wiring of Modbus RTU (RS485) must be carried out in accordance with the standard ANSI/TIA/EIA-485-A-1998.

Galvanic separation shall be provided for segments crossing buildings.

Common ground shall be used for all devices on the same network inclusive router, gateways etc.

All bus connections in the cables are made with twisted pair wires.

The recommended cable type for this is AWG 22/0.32 mm². If used for longer distances please use a AWG 20/0.5mm² or AWG 18/0.75mm²

cable. The cables characteristic impedance shall be between 100 – 130Ω The capacitance between conductors shall be less than 100 pf

per meter.

Note: the length of the cables influence the communication speed used. Longer cable lengths mean lower baud rate should be used.

Maximum cable length allowed is 1200m.

Use a minimum 20 cm distance between 110V/230V/400V power line cables and bus cables.

Maintenance/Service/

Disposal

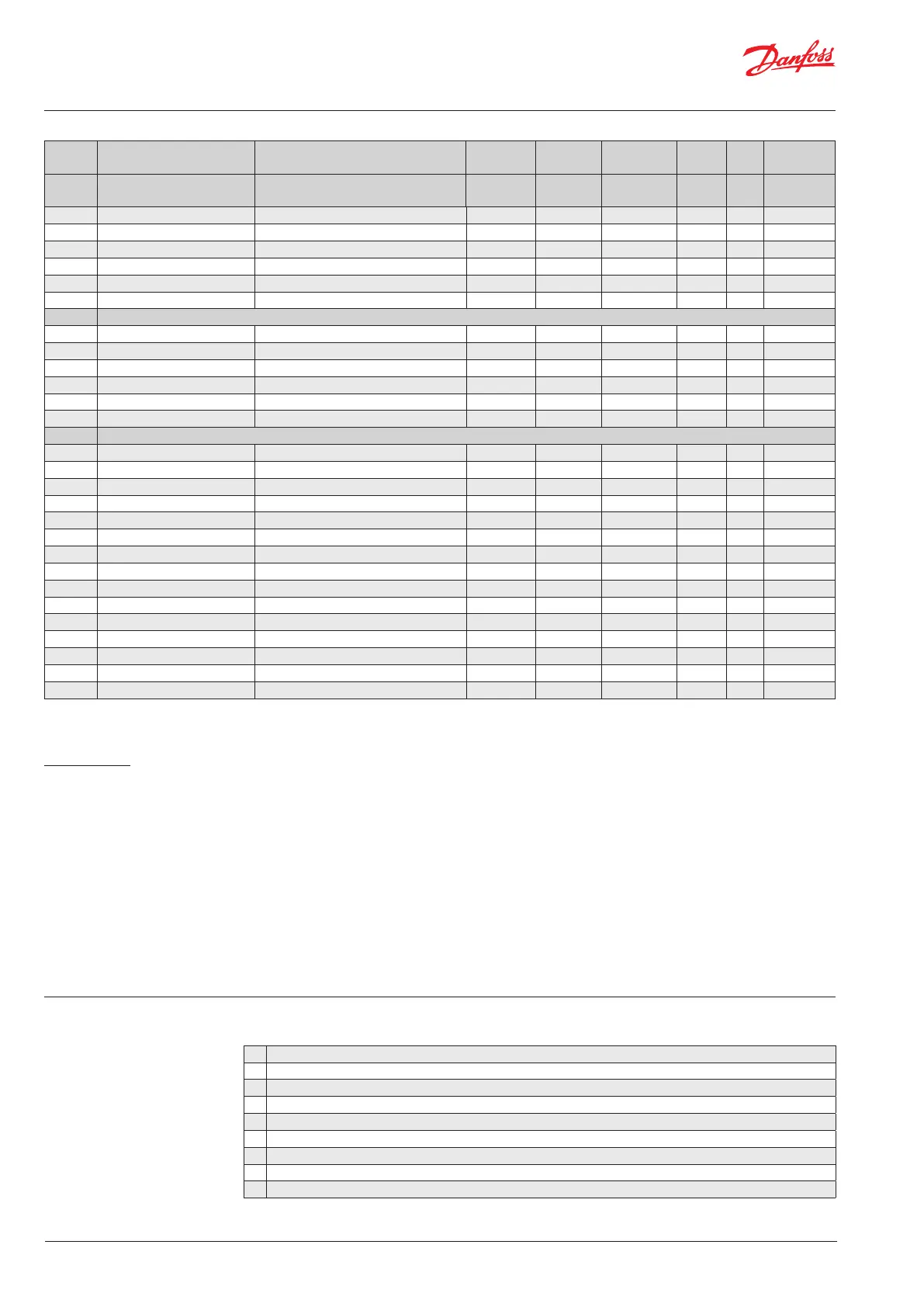

Table 02

Maintenance checklist - Perform once a year minimum

1 Use P&I dagram and check that all powered components are working properly

2 Check for alarms in the MCX controller

3 Fans, air filters and fins must be cleaned for dirt and dust

4 Expansion valve must be inspected and must be replaced if damaged

5 Ensure expansion valves sensor bulb has good contact with suction line

6 Replace water in water bubble bath. Check pH level frequently and replace when pH > 12.6

7 Check cover is mounted correctly and all bolts are tightened accordingly

8 Check and verify the amperage of the unit

9 Check for abnormal compressor noises in normal operating conditions (may indicate loose bolts, worn bearings or pistons)

Loading...

Loading...