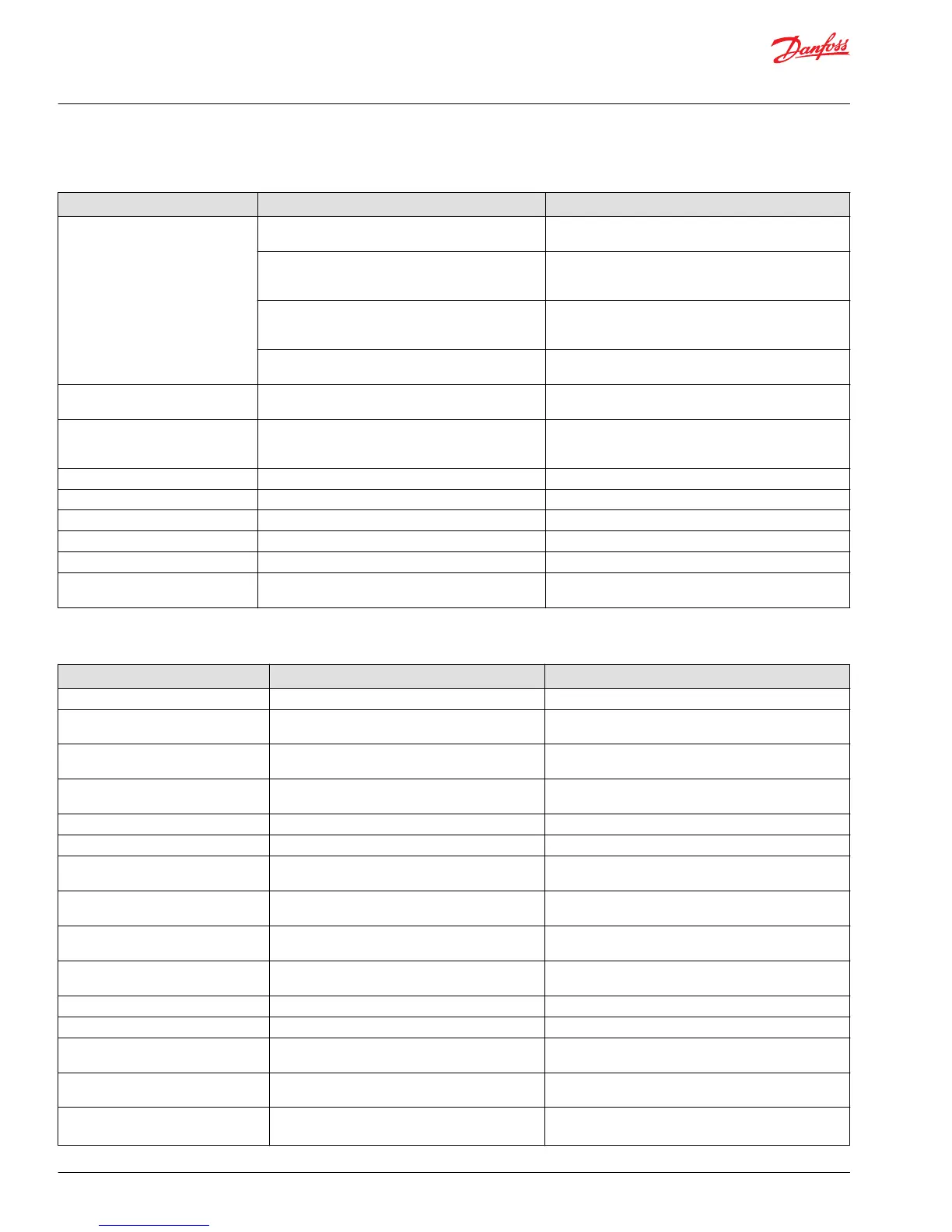

Cylinder/motor responds in one direction only

Cause Check Corrective action

Verify if fault is mechanical, electrical

or hydraulic

Operate manual lever in both directions to confirm if

mechanical or electrical or hydraulic

If moving the manual lever operates the cylinder/motor

in both directions check electrical or hydraulic

If operating the manual lever strokes the cylinder/

motor in one direction only, check manual stop screw

adjustment

Back out manual stop on manual controller and torque

the jam not to 8 Nm [70 lbf•in] Do not exceed maximum

torque

Check movement of manual lever when electrical

controller is operated

If manual lever does not move in one direction check

electrical signal from controller and wiring at the PVE

module

Check movement of manual lever when hydraulic

controller is operated

If manual lever does not move in both directions check

hydraulic pressure at the PVG module

Air in system Entrained air generates heat under pressure Look for foam or bubbles in reservoir. Check for leaks on

inlet side of charge pump.

Internal leakage Excessive internal leakage may overheat the system. Install loop flushing defeat option and monitor case flow.

If case flow is excessive, motor may require major repair.

Contact Danfoss Service.

Shock valves Swap and see if problem follows Replace valves

Solenoid actuation If power is OK from controller Repair wiring to PVE module

Main spool travel restricted Stop on manual controller turned in too far Back out manual stop on manual controller

Remote electrical controller Insufficient signal from electrical controller Repair or replace electrical controller

PVEO connections Incorrect PVE/PVEO connections Connect correct way

Remote hydraulic controller PVRH Insufficient pilot oil pressure from remote hydraulic

controller Pressure needs to be 25 Bar [360 psi]

Repair or replace remote hydraulic controller

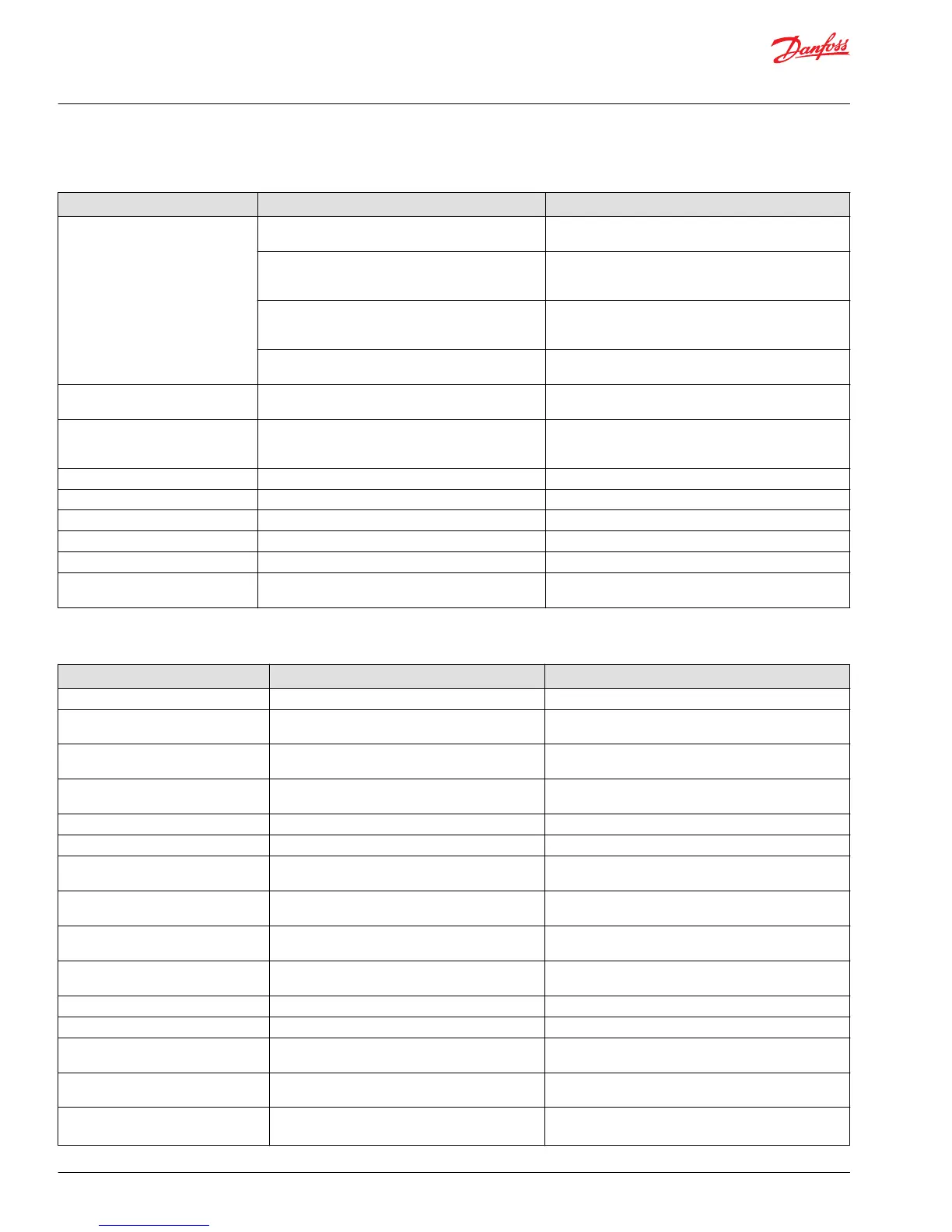

Main valve spool moves without oil passing to cylinder/motor

Cause Check Corrective action

Insufficient oil supply to valve Check the pump per manufacturers procedure Repair or replace pump per manufacturers procedure

Optional pressure compensator in

valve section not functioning

Check compensator spool Replace spool

Insufficient load pressure at

compensator spring chamber

LS drilling holes plugged Clean or replace

Cylinder/motor load too high for

pressure setting of the system

Check pressure at the valve If pressure is set to spec. per valve lower load on cylinder/

motor

Blocked LS galleries Inspect for blockage in LS galleries Remove blockage in LS galleries

Shuttle valve faulty Inspect shuttle valve Repair or replace

Blocked LS lines to pump controller Inspect LS lines from PCG to pump controller Remove blockage in LS lines from the PVG valve to pump

controller

Oil bypassing at shock valve/anti-

cavitation check valve

Check if stuck open or damaged Replace valve

Internal leakage in cylinder/motor Inspect for by-passing of oil per cylinder/motor

manufacture per manufactures procedure

Repair or replace cylinder/motor per manufactures

procedure

Too much leakage in LS spool in pump

control

Check bleed orifice in LS control Use a LS pump control with no bleed orifice

Blocked thermal orifice check thermal orifice (blocked) Replace thermal orifice

Load too high for system Check for proper system pressure Adjust pressure to valve specification

Internal leakage in cylinder/motor Inspect for bypassing of oil per cylinder/motor

manufacturer specification

Repair or replace cylinder/motor

Shock valve or anti-cavitation check

valve faulty

Inspect for damage and contamination Repair or replace cylinder/motor

System relief valve pressure set too low

for load

Install pressure gauge and check pressure

Adjust pressure to system specification

Lower load

Service Manual

PVG 32 Proportional Valve Group

System Troubleshooting

16 |

©

Danfoss | February 2017 11039167 | AX00000031en-US0301

Loading...

Loading...