VLT

®

5000/6000/8000 Series

■

Transportation and uncrating

To lessen the possibility of damage it is recommended

that th

e crated VLT frequency converter is

located as close to the final installation site

as possible before uncrating.

Door and ceiling clearances must be considered when

moving and installing the VLT frequency converter.

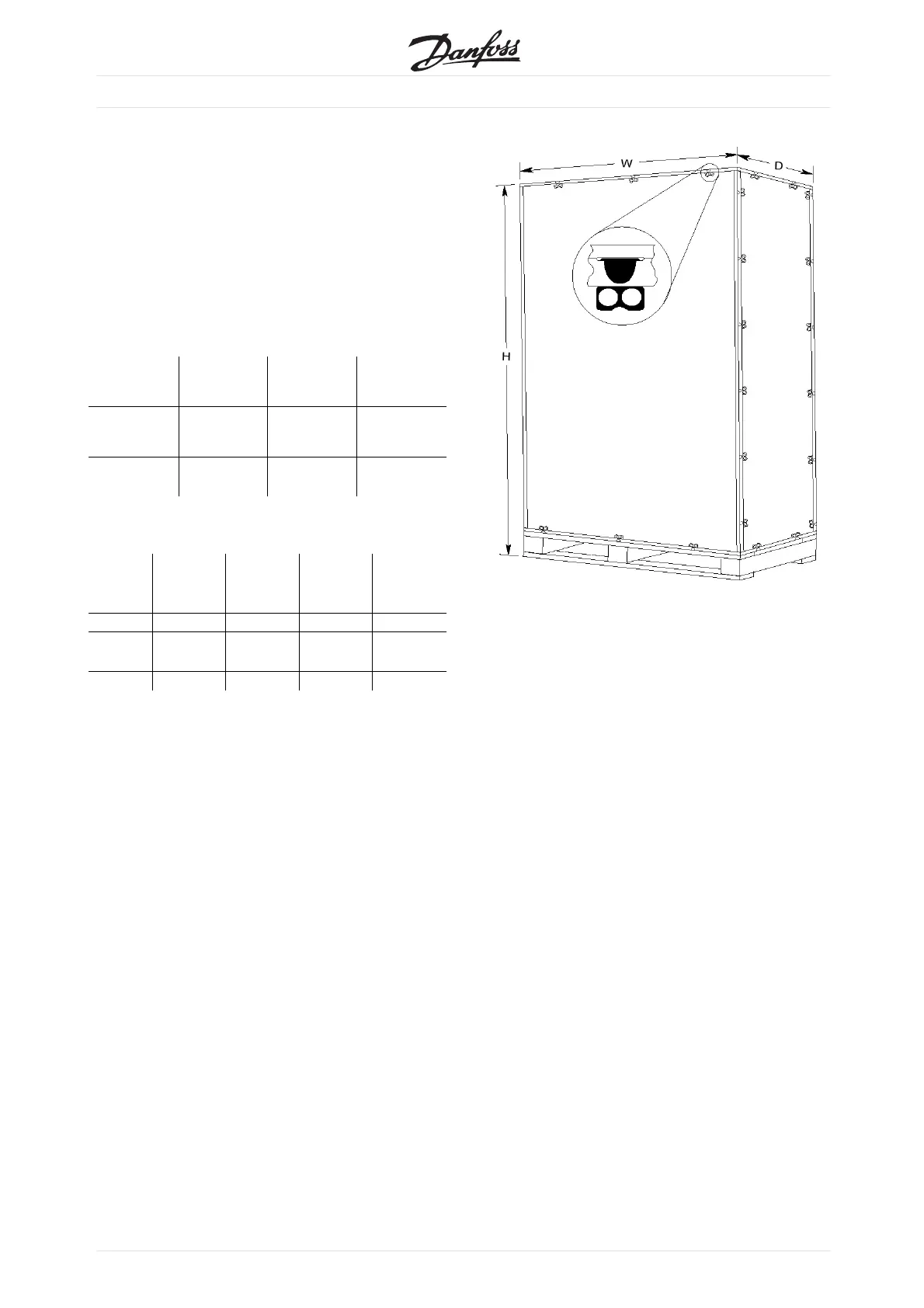

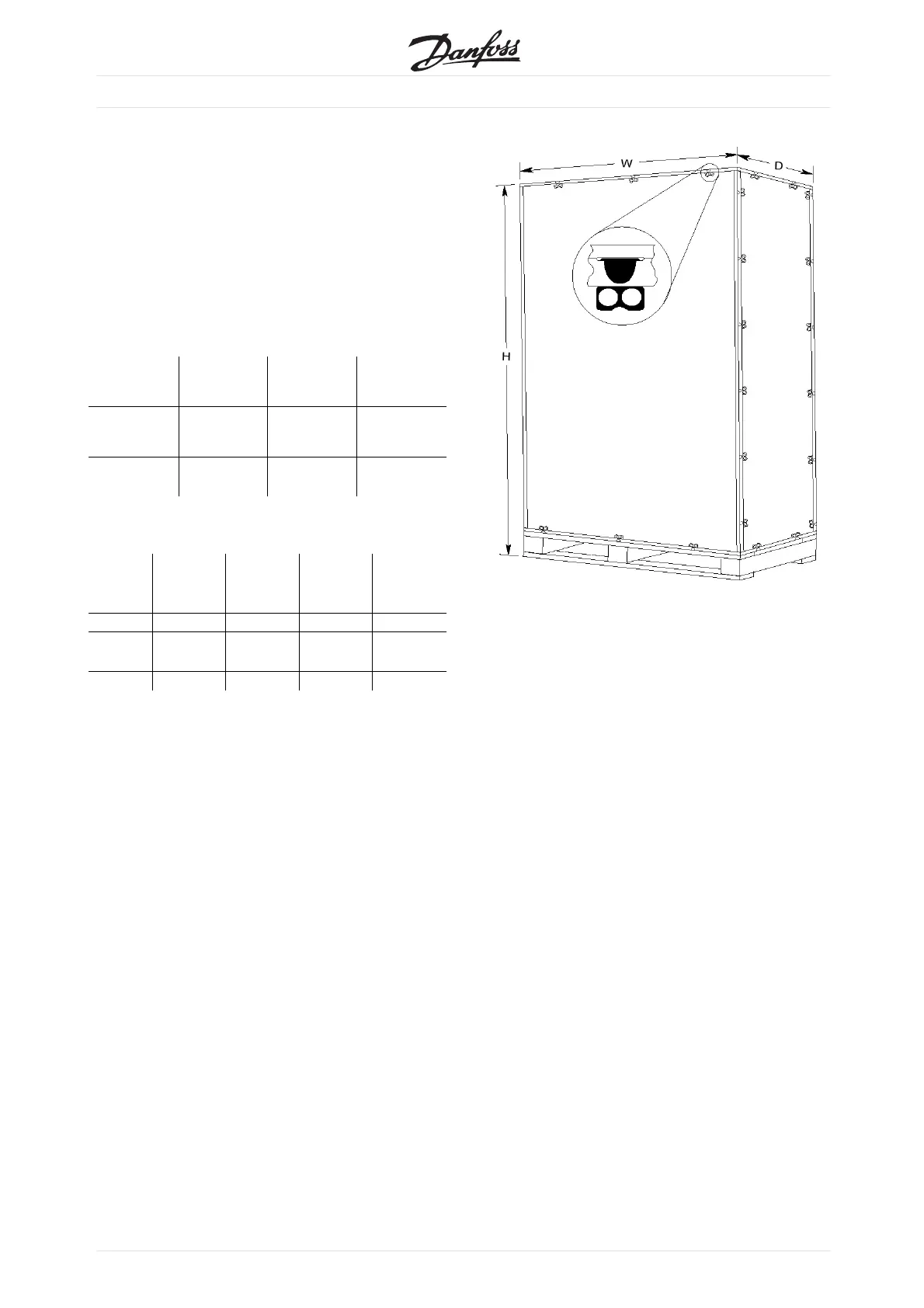

Seebelowtableforthecratedimensions:

Dimensions mm (inches):

H W D

IP 00 2096

(82.52)

1219

(48.0)

699

(27.52)

Nema 1 (IP

20) / 54

2324

(91.5)

1321

(52.0)

724

(28.5)

Weight kg (lbs):

VLT

5300/6350/

8350/8550

VLT

5350/6400/

8350/8550

VLT

5450/6500/

8350/8550

VLT

5500/6550/

8350/8550

IP 00 548 (1208) 583 (1385) 628 (1385) 653 (1440)

Nema 1

(IP 20)

654 (1442) 689 (1519) 734 (1618) 759 (1673)

IP 54 664 (1464) 699 (1541) 744 (1640) 769 (1695)

A qualified person with a forklift or other similar

lifting device will be needed to remove the VLT

frequency converter from the crate.

To open the crate:

•

Remove the metal locking tabs that secure the top

panel of the crate, this will give access to the lifting

rings on the top of the VLT frequency converter.

•

On IP 00 versions remove the supporting

brace bolted to the lifting rings.

•

A forklift or similar lifting device should be

used at this time to ensure the stability of the

VLT frequency converter while the rest of the

crate is removed. Position the lifting device

to the front side of the crate.

•

The VLT frequency converter should be lifted using

a spreader bar or other similar lifting device. Lift the

V

LT frequency converter slightly, using all four lifting

rings, distributing the weight as evenly as possible.

MG.56.A2.02 - VLT is a registered Danfoss trademark

4

Loading...

Loading...