3.3.3 Inverter Section

In the inverter section (see Figure 3.7), gate signals are

delivered from the control card, through the power card

and gate drive card to the gates of the IGBTs. The series

connection of each set of IGBTs is delivered to the output,

first passing through the current sensors.

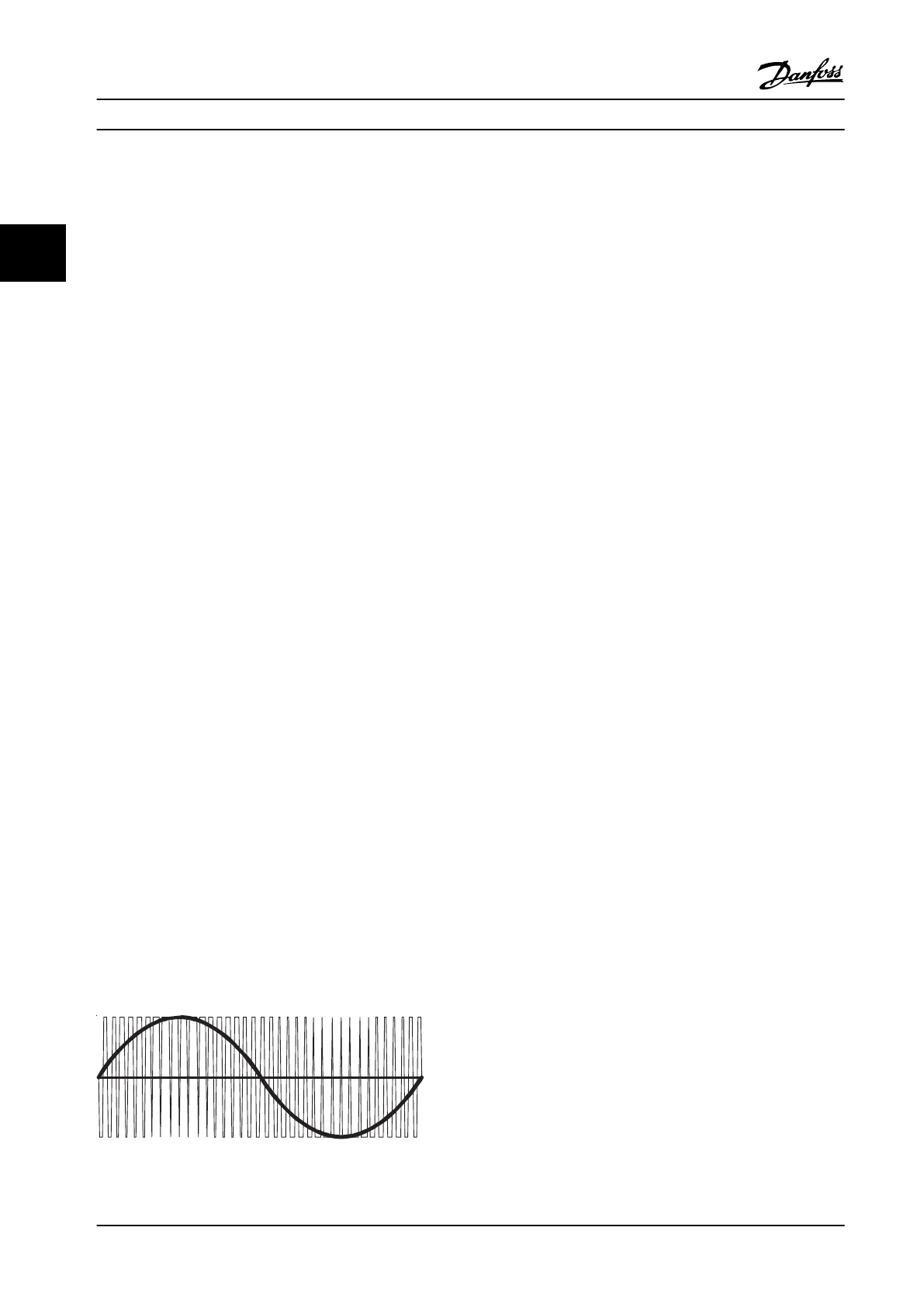

Once a run command and speed reference are present, the

IGBTs begin switching to create the output waveform, as

shown in Figure 3.6. Looking at the phase-to-phase voltage

waveform with an oscilloscope, the pulse width

modulation (PWM) principal creates a series of pulses

which vary in width. Basically, the pulses are narrower as

zero crossing is approached and wider the farther from

zero crossing. The pulse duration of applied DC voltage

controls the width. Although the voltage waveform is a

consistent amplitude, the inductance within the motor

windings averages the voltage delivered so, as the pulse

width of the waveform varies, the average voltage the

motor detects also varies. The resultant current waveform

takes on the sine wave shape common to an AC system.

The rate at which the pulses occur determines the

frequency of the waveform. By employing a sophisticated

control scheme, the adjustable frequency drive delivers a

current waveform that nearly replicates a true AC sine

wave.

Hall effect current sensors monitor the output current and

deliver proportional signals to the power card where they

are buffered and delivered to the control card. The control

card logic uses these current signals to determine proper

waveform compensations based on load conditions. They

further serve to detect overcurrent conditions, including

ground faults and phase-to-phase shorts on the output.

During normal operation, the power card and control card

are monitoring various functions within the adjustable

frequency drive. The current sensors provide current

feedback information. The DC bus voltage is monitored as

well as the voltage delivered to the motor. A thermal

sensor mounted inside each IGBT module provides

heatsink temperature feedback.

Figure 3.6 Output Voltage and Current Waveforms

Internal Adjustable Frequen... Service Manual

40 Danfoss A/S © Rev. 2014-02-10 All rights reserved. MG94A222

33

Loading...

Loading...