4. Electrical installation

4.1. How to connect

4.1.1. Cables General

NB!

Cables General

Always comply with national and local regulations on cable cross-sections.

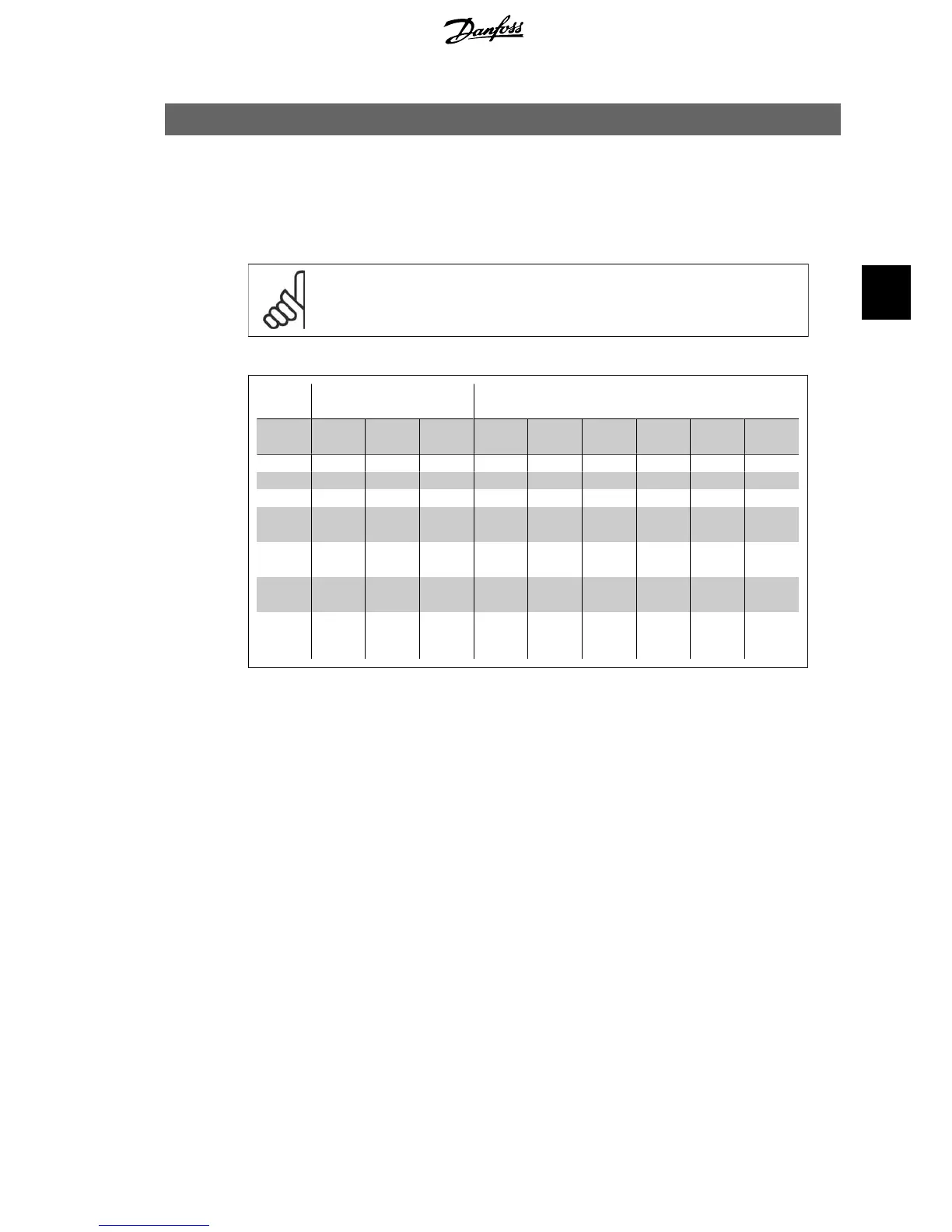

Details of terminal tightening torques.

Power (kW) Torque (Nm)

Enclo-

sure

200-24

0 V

380-48

0 V

525-60

0 V

Line Motor

DC con-

nection

Brake Earth Relay

A2 1.1 - 3.0 1.1 - 4.0 1.1 - 4.0 1.8 1.8 1.8 1.8 3 0.6

A3 3.7 5.5 - 7.5 5.5 - 7.5 1.8 1.8 1.8 1.8 3 0.6

A5 1.1 - 3.7 1.1 - 7.5 1.1 - 7.5 1.8 1.8 1.8 1.8 3 0.6

B1 5.5 - 11

11 -

18.5

- 1.8 1.8 1.5 1.5 3 0.6

B2

-

15

22

30

-

-

2.5

4.5

2.5

4.5

3.7

3.7

3.7

3.7

3

3

0.6

0.6

C1

18.5 -

30

37 - 55 - 10 10 10 10 3 0.6

C2

37

45

75

90

-

-

14

24

14

24

14

14

14

14

3

3

0.6

0.6

Table 4.1: Tightening of terminals.

4.1.2. Fuses

Branch circuit protection

In order to protect the installation against electrical and fire hazard, all branch circuits in an in-

stallation, switch gear, machines etc., must be shortcircuit and overcurrent protected according

to the national/international regulations.

Short circuit protection

The frequency converter must be protected against short-circuit to avoid electrical or fire hazard.

Danfoss recommends using the fuses mentioned in tables 4.3 and 4.4 to protect service personnel

or other equipment in case of an internal failure in the unit. The frequency converter provides full

short circuit protection in case of a short-circuit on the motor output.

Over-current protection

Provide overload protection to avoid fire hazard due to overheating of the cables in the installation.

Over current protection must always be carried out according to national regulations. The fre-

quency converter is equipped with an internal over current protection that can be used for

upstream overload protection (UL-applications excluded). See VLT

®

HVAC Drive Programming

Guide, par. 4-18. Fuses must be designed for protection in a circuit capable of supplying a maxi-

mum of 100,000 A

rms

(symmetrical), 500 V/600 V maximum.

VLT

®

HVAC Drive Operating Instructions 4. Electrical installation

MG.11.A4.02 - 09.10.06. VLT

®

is a registered Danfoss trademark

21

4

Loading...

Loading...