1.4.2 Block Diagram of the Frequency

Converter

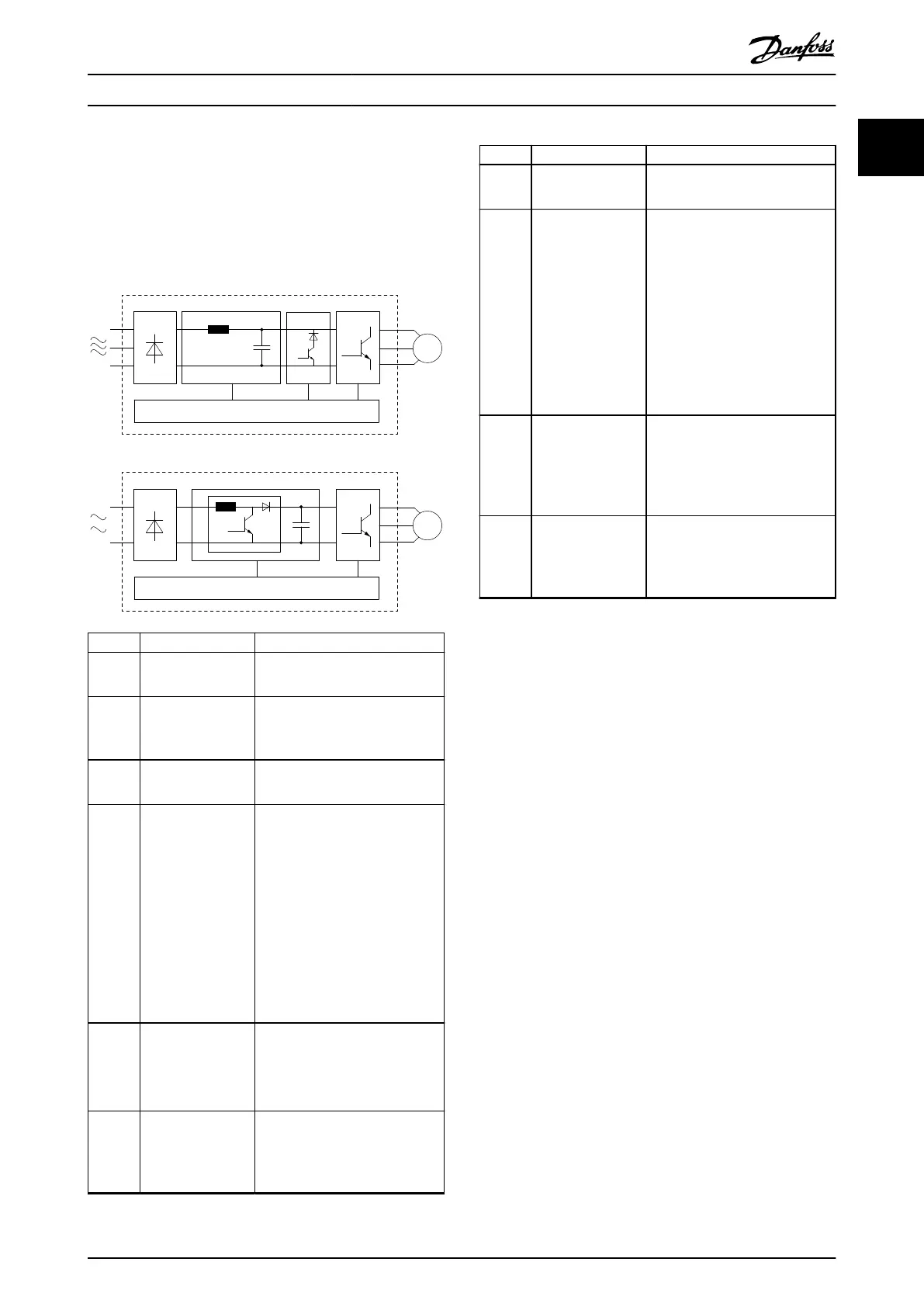

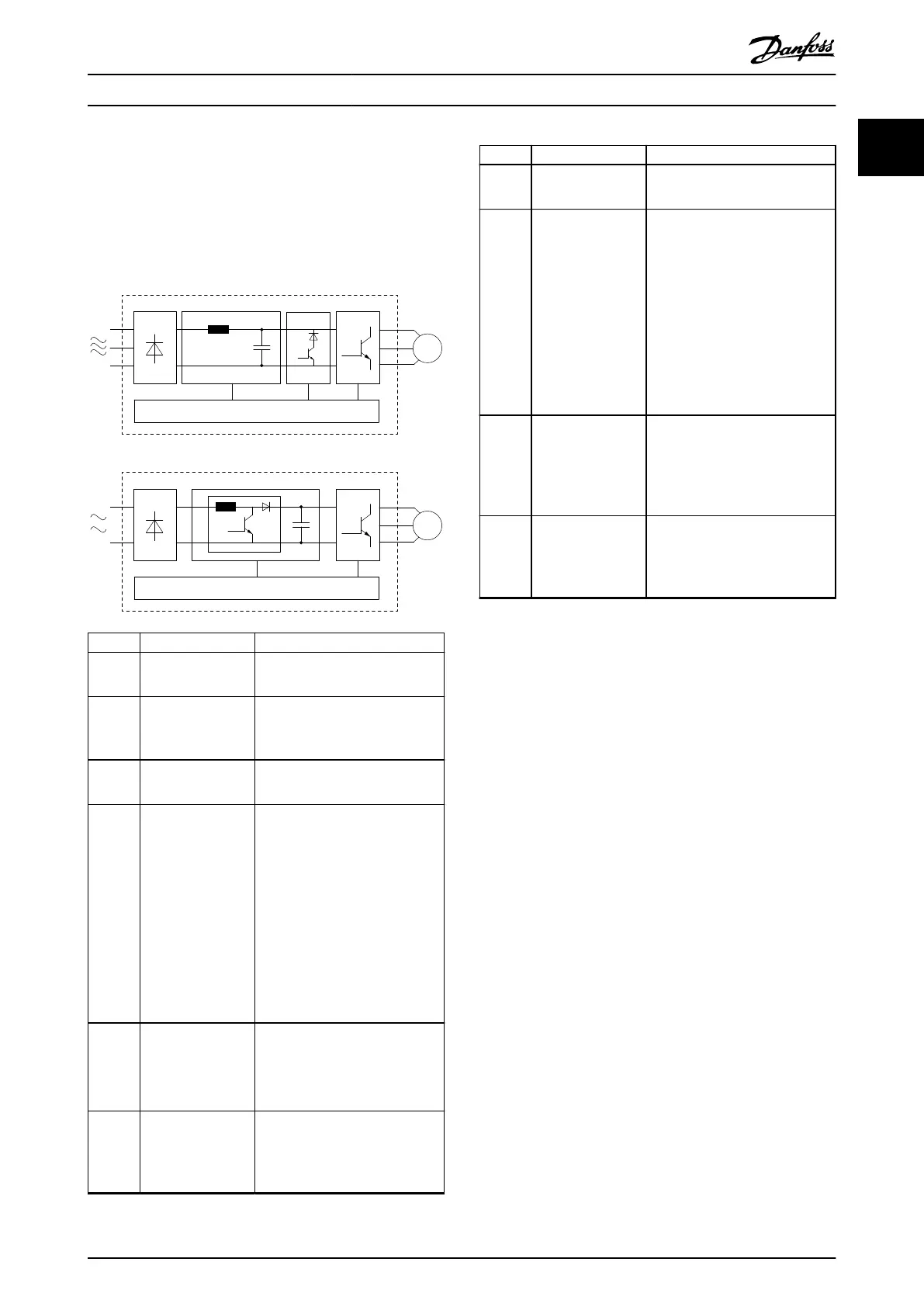

Illustration 1.1 is a block diagram of the internal

components of the frequency converter.

M

7

63

4

5

21

8

10

130BE200.12

M

7

63

4

5

21

8

9

T2/T4

S2

Area Component Functions

1 Mains input

•

AC mains supply to the

frequency converter.

2 Rectier

•

The rectier bridge converts

the AC input to DC current to

supply inverter power.

3 DC bus

•

Intermediate DC-bus circuit

handles the DC current.

4 DC reactor

•

Filters the intermediate DC

circuit current.

•

Provides mains transient

protection.

•

Reduces the root mean square

(RMS) current.

•

Raises the power factor

reected back to the line.

•

Reduces harmonics on the AC

input.

5 Capacitor bank

•

Stores the DC power.

•

Provides ride-through

protection for short power

losses.

6 Inverter

•

Converts the DC into a

controlled PWM AC waveform

for a controlled variable

output to the motor.

Area Component Functions

7 Output to motor

•

Regulated 3-phase output

power to the motor.

8 Control circuitry

•

Input power, internal

processing, output, and motor

current are monitored to

provide ecient operation

and control.

•

User interface and external

commands are monitored and

performed.

•

Status output and control can

be provided.

9 PFC

•

Power factor correction

changes the waveform of

current which is drawn by the

frequency converter to

improve the power factor.

10 Brake chopper

•

Brake chopper is used in the

DC intermediate circuit to

control DC voltage when the

load feeds energy back.

Illustration 1.1 Example of Block Diagram for a Frequency

Converter

1.4.3 Enclosure Sizes and Power Ratings

For enclosure sizes and power ratings of the frequency

converters, refer to chapter 9.9 Enclosure Sizes, Power

Ratings, and Dimensions.

1.4.4 Safe Torque O (STO)

The VLT

®

Midi Drive FC 280 frequency converter supports

Safe Torque O (STO). See chapter 6 Safe Torque O (STO)

for details about the installation, commissioning,

maintenance, and technical data of STO.

Introduction Operating Guide

MG07A402 Danfoss A/S © 10/2017 All rights reserved. 5

1 1

Loading...

Loading...