Chapter 5 – Maintenance and Adjustments 57

5

5

5

M

M

M

a

a

a

i

i

i

n

n

n

t

t

t

e

e

e

n

n

n

a

a

a

n

n

n

c

c

c

e

e

e

a

a

a

n

n

n

d

d

d

A

A

A

d

d

d

j

j

j

u

u

u

s

s

s

t

t

t

m

m

m

e

e

e

n

n

n

t

t

t

s

s

s

5

5

5

.

.

.

1

1

1

C

C

C

l

l

l

e

e

e

a

a

a

n

n

n

i

i

i

n

n

n

g

g

g

I

I

I

n

n

n

t

t

t

e

e

e

r

r

r

v

v

v

a

a

a

l

l

l

s

s

s

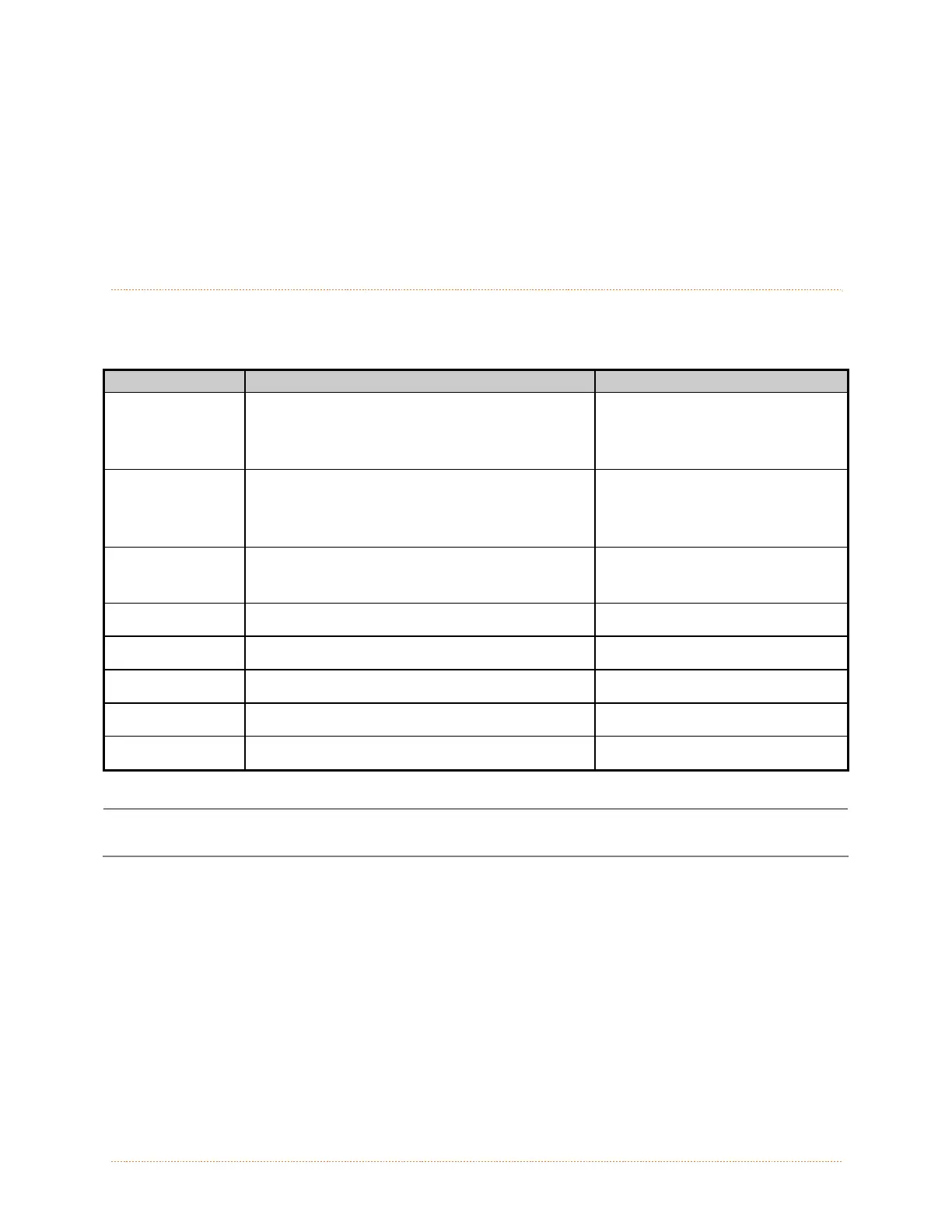

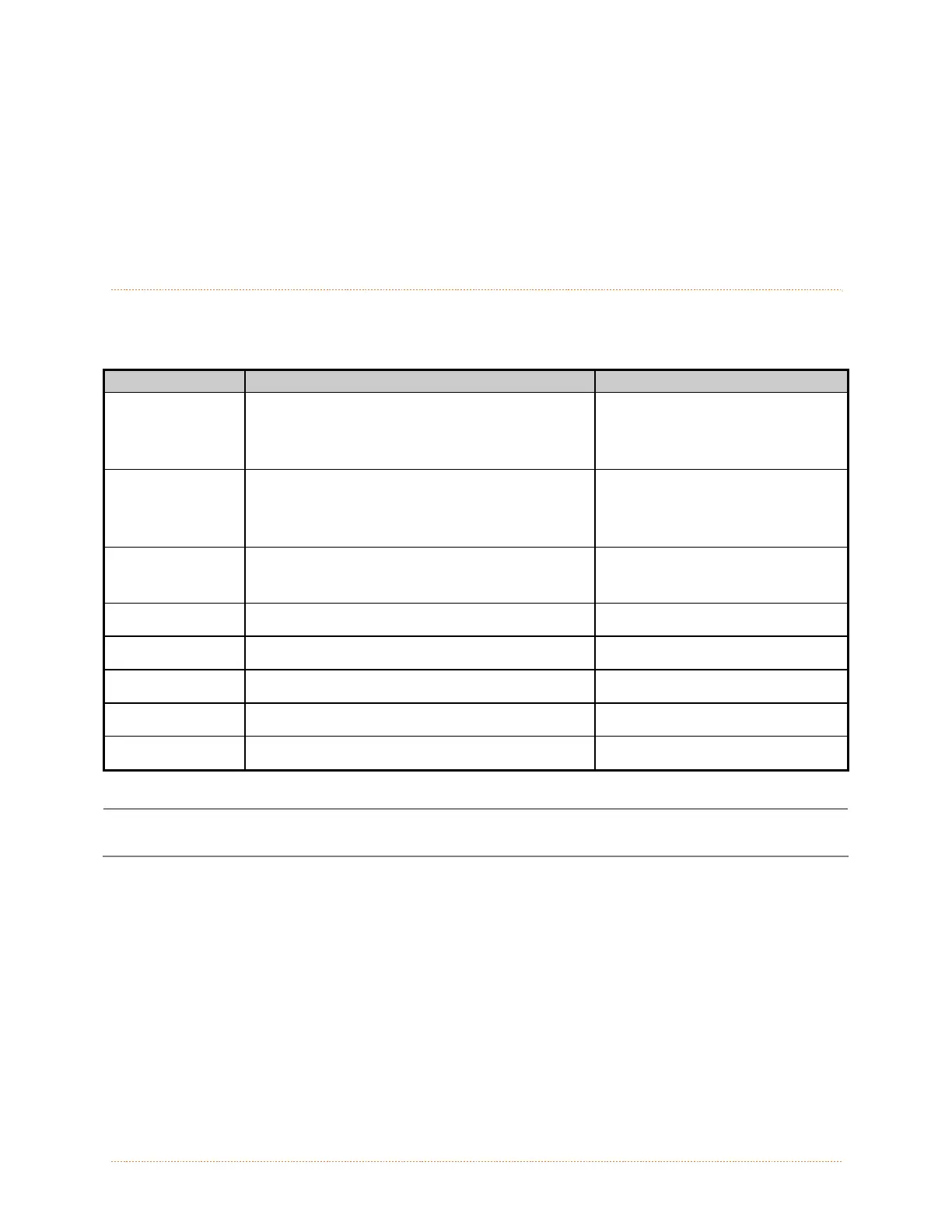

This section details the cleaning, adjusting, and troubleshooting tips for the printer. The following

table outlines the recommended maintenance schedule for the various printer parts.

Area Method Interval

Printhead Turn off the printer before cleaning the

printhead. Use solvent* on a cotton swab to

clean the printhead from end to end.

After every roll of media.

Platen Roller Turn the power off. Rotate the platen roller and

clean it thoroughly with solvent* and a cotton

swab.

After every roll of media.

Peel-Off Roller Rotate the peel-off roller and clean it thoroughly

with solvent* and a cotton swab.

After every roll of media.

Media Path

Solvent* After every roll of media.

Peel/Tear Bar

Solvent* As needed

Media Sensor

Air blow Monthly

Exterior

Mild detergent or desktop cleaner. As needed

Interior

Brush or vacuum cleaner As needed.

* It is recommended that a solvent containing isopropyl alcohol be used.

Isopropyl alcohol is a flammable solvent; always take the proper precautions when using this

substance.

Proper cleaning is critical. To maintain peak performance of the printer, Datamax-O’Neil offers a

complete line of cleaning products including pens, cards, films and swabs. Visit our website at

http://www.datamax-oneil.com to learn more.

Certified Datamax-O’Neil – The worry free choice for optimal printer performance

Loading...

Loading...