31

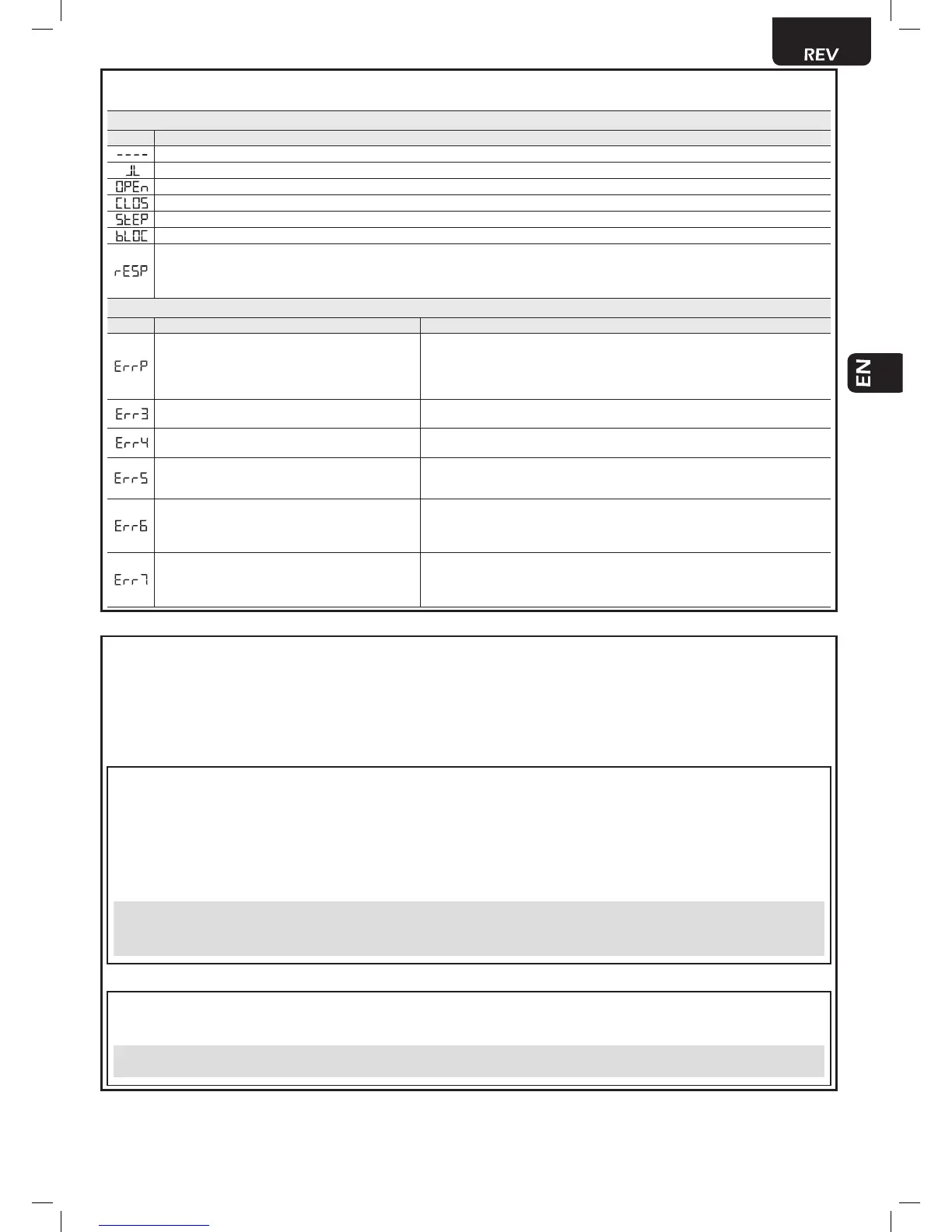

8 MESSAGES SHOWN ON THE DISPLAY

WORKING STATUS MESSAGES

Mess. Description

Gateisclosed

Gateisopened

Openingunderway

Closingunderway

Whileinstep-by-stepmode,thecontrolboardawaitsfurtherinstructionsafterastartcommand

Stopcommandreceived

Resetcurrentposition:Thecontrolunithasjustbeenturnedonafterapowerfailure,orthegatehasexceededthemaximumnumber(80)

ofinversionsallowedwithoutevergettingtotheclosingstroke,orthemaximumnumber(3)ofconsecutiveoperationsallowedoftheanti-

crushingdevice.

Oncethecontrolunithasbeenresetandopencommandgiventhegatewillstartmovingatslowspeed,untilitreachesendoftravel.

ERROR MESSAGES

Mess. Description

Possible solutions

Errorposition:Theresetpositionprocedureisnotsuc-

cessful.Thecontrolpanelisawaitingcommands.

-Makesuretherearenospecificfrictionsand/orobstaclesduringtherun;

-Giveastartpulsetoinitiateapositionresetprocedure;

-Verifythattheoperationiscompletedsuccessfully,manuallyhelpingtherun,if

necessary;

-Adjustpowerandspeedsettingsifnecessary.

Externalphotocellsand/orsafetydevicesareactivat-

edoroutoforder.

-Makesurethatallsafetydevicesand/orphotocellsinstalledareworkingproperly.

Possiblefailuretothecontrolboardpowercircuit.

-Disconnectandconnectpowersupply.Giveastartimpulse,ifthiserrorappears

again,replacethecontrolboard.

Time-outoperatorsrun: The engine/sexceeded the

maximum operating time (5min) without ever stop-

ping.

-Giveastartpulsetostartthepositionresetprocedure;

-Ensurethatthisoperationissuccessful.

Time-outobstacledetection:Withanti-crushingsen-

sordisabled,wasstilldetectedthepresenceofanob-

staclethatpreventsmovementoftheleafforaperiod

of10secondsmore.

-Makesuretherearenospecificfrictionsand/orobstaclesduringtherun;

-Giveastartpulsetoinitiateapositionresetprocedure;

-Verifythattheoperationiscompletedsuccessfully.

Operatorsmouvementnotdetected.

-Makesurethatoperatorsandencodersconnectionsarewelldone.

-CheckthatjumpersJ5andJ9arewellpositionedasshownontheelectricwiring

(for24Vonly).

-Ifthiserrorappearsagain,replacethecontrolpanel.

9 START-UP

Thestart-upphaseisveryimportanttoensuremaximumsecurityandcompliancetoregulations,includingalltherequirementsof

EN12445standardwhichestablishesthetestmethodsfortestingtheautomationforgates.

DEASystemremindsthatallinstallation,maintenance,cleaningorrepairoperationsonanypartofthesystemmustbeperformed

exclusivelybyqualifiedpersonnelwhomustberesponsibleofalltextsrequiebytheeventualrisk;

9.1 Installation test

Thetestingoperationisessentialinordertoverifythecorrectinstallationofthesystem.DEASystemwantstosummarizethe

propertestingofalltheautomationin4easysteps:

• Makesurethatyoucomplystrictlyasdescribedinparagraph2“WARNINGSSUMMARY”;

• Testtheopeningandclosingmakingsurethatthemovementoftheleafmatchasexpected.Wesuggestinthisregardtoperform

variousteststoassessthesmoothnessofthegateanddefectsinassemblyoradjustment;

• Ensurethatallsafetydevicesconnectedworkproperly;

• Performthemeasurementofimpactforcesinaccordancewiththestandard12445tofindthesettingthatensurescompliance

withthelimitssetbythestandardEN12453.

WARNING UsingsparepartsnotindicatedbyDEASystemand/orincorrectre-assemblycancreatearisktopeople,animals

andpropertyandalsodamagetheproduct.Forthisreason,alwaysuseonlythepartsindicatedbyDEASystemandscrupulously

followallassemblyinstructions.

9.2 Unlocking and Manual operation

Intheeventofmalfunctionsorsimplepowerfailure,releasethemotor(Pic.8)andperformtheoperationmanually.

Theknowledgeoftheunlockingoperationisveryimportant,becauseintimesofemergencythelackoftimelinessinactingon

suchadevicecanbedangerous.

WARNINGTheefficancyandsafetyofmanualoperationoftheautomationisguaranteedbyDEASystemonlyiftheinstallation

hasbeeninstalledcorrectlyandwithoriginalaccessories.

Loading...

Loading...