User_Manual-PILATUS-V1_2.doc 10/57

The great advantage of this approach is that standard technologies are used

for both the silicon sensor and the CMOS readout chips, which guarantees

highest quality. Both processes are optimized separately, as the best silicon

substrates for X-ray detection and for high-speed/high-quality electronics are

very different. Moreover, the small size of the pixel and of the interconnection

results in a very low capacitance, which has the beneficial effect of reducing

the noise and power consumption of the pixel readout electronics.

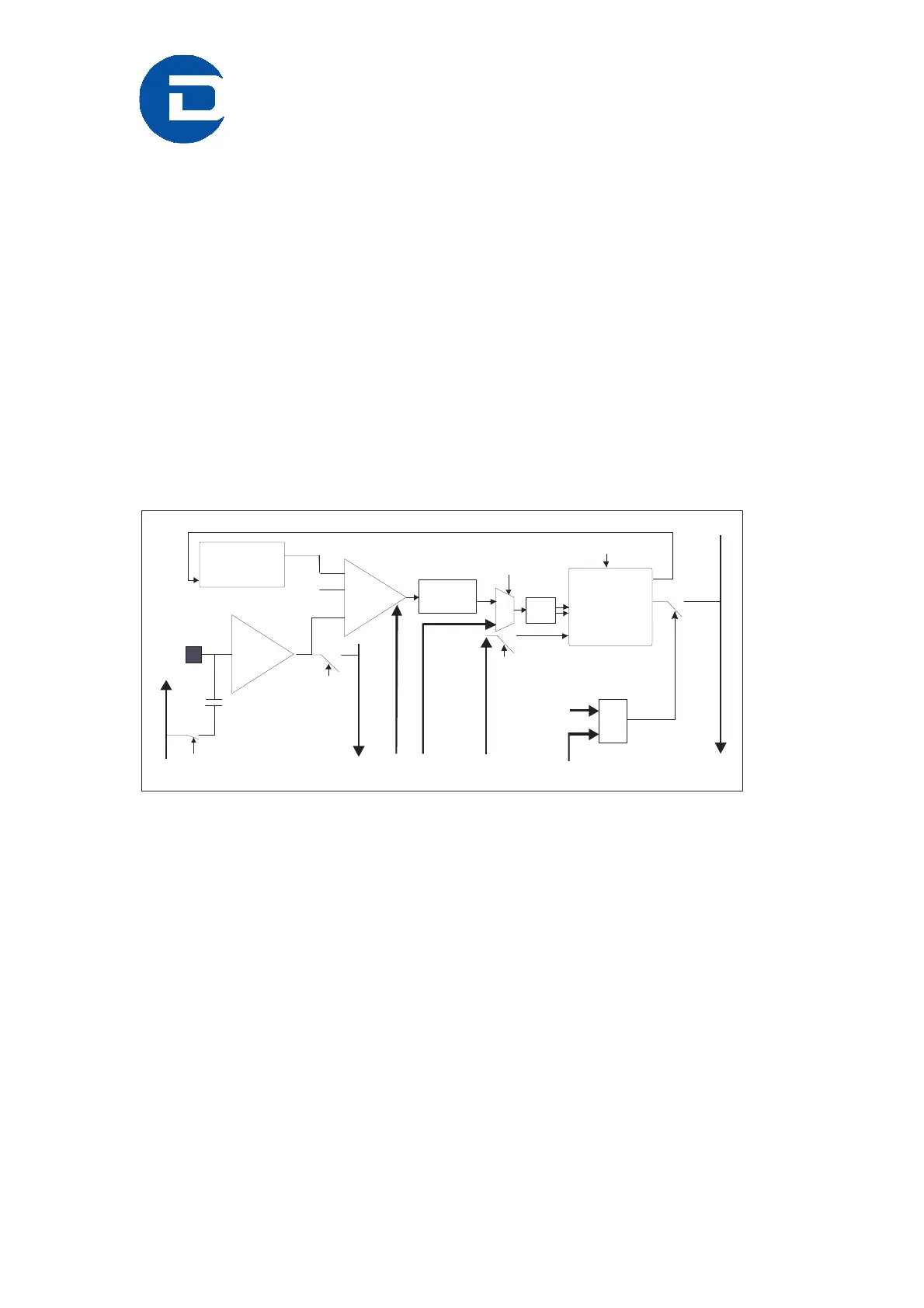

X-ray data collection can be improved with detectors operating in single

photon counting mode. A hybrid pixel which features single photon counting

comprises a preamplifier, which amplifies the charge generated in the sensor

by the incoming X-ray, and a discriminator, which produces a digital signal if

the incoming charge exceeds a pre-defined threshold. The discriminator feeds

a 20 bit counter, which then leads to completely digital storage and noiseless

readout of the number of detected X-rays in each pixel (Figure 4)

Global

Tresh

6 Bit Latch

+ DAC

CS

Amp

Comp

Bump

Pad

DOUTAOUT

Rowsel

Pixsel

Pixsel

Pixsel

Pixsel

Colsel

-

+

CAL

1.6fF

20 bit

Counter

Pixsel

Pixsel

&

PILATUS II Pixel Cell

DCLK

ENA

Pulse

Shaper

DIN

φ

1

-

Gen

φ

2

CNT/RO

Figure 4 Block diagramm of the CMOS chip

The fundamental unit of the DECTRIS detectors consists of a single fully

depleted monolithic silicon sensor with an 8 x 2 array of CMOS readout chips

bump-bonded to it. Each sensor is a continuous array of 487 x 197 = 94965

pixels without dead areas and covers an active area of 83.8 x 33.5 mm

2

. The

readout chips are wire-bonded to the mounting bracket with its readout control

electronics and forms the complete module (Figure 3).

Loading...

Loading...