2. Programming Concepts

14. Example 1: Connect 1 Master and 2 Slaves by RS-485 and exchange 16 data between Master

and Slaves through PLC LINK

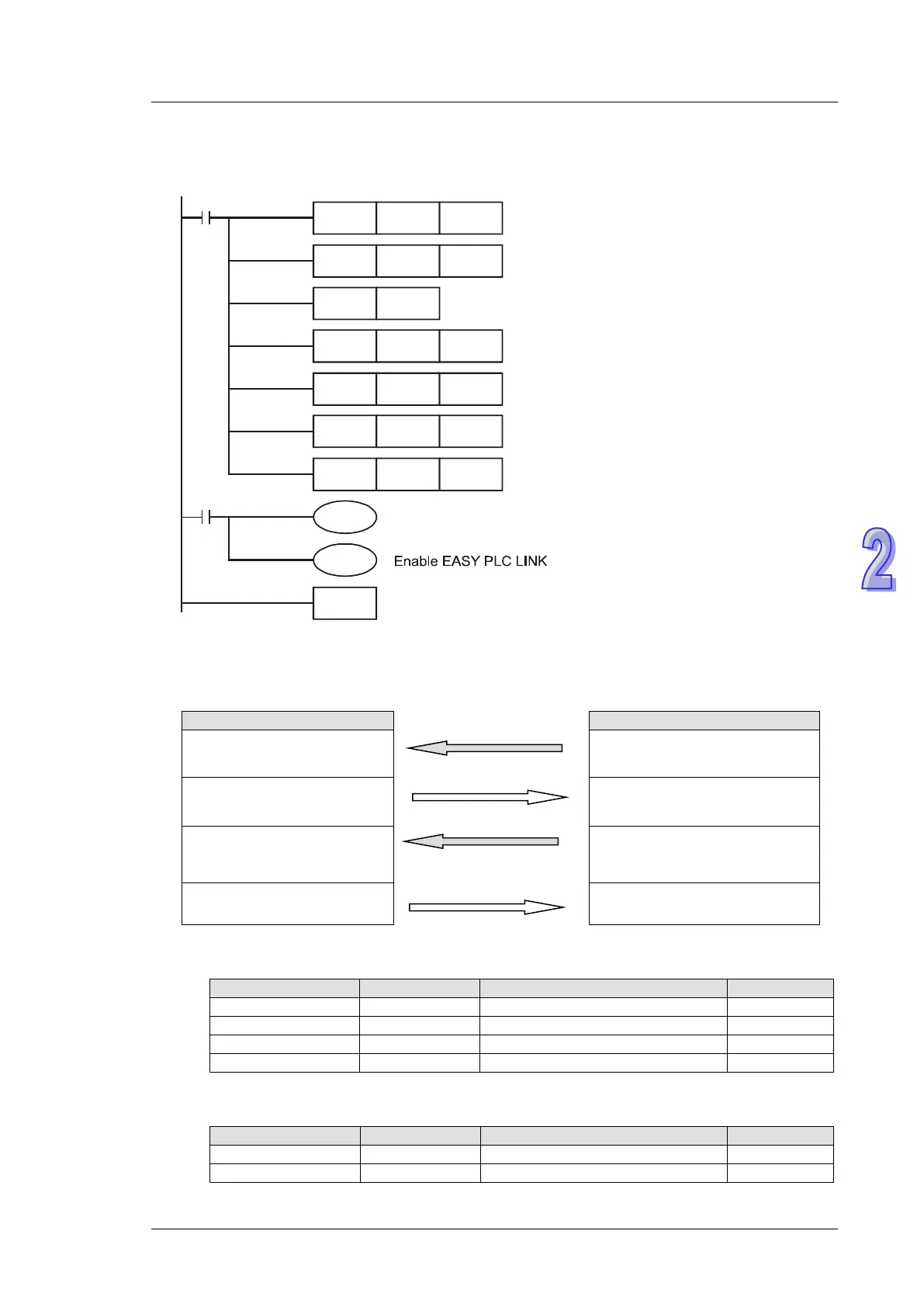

a) Write the ladder diagram program into Master PLC (ID#17)

M1002

MOV K17 D1121

H86 D1120

K16

K16

M1351

END

MOV

SET M1120

MOV

MOV

D1434

D1450

M1350

X1

K16

K16

MOV

MOV

D1435

D1451

Master ID#

COM2 communication protocol

Retain communication protocol

Data length to be read from Slave ID#1

Data length to be written into Slave ID#1

Data length to be read from Slave ID#2

Data length to be written into Slave ID#2

Auto mode

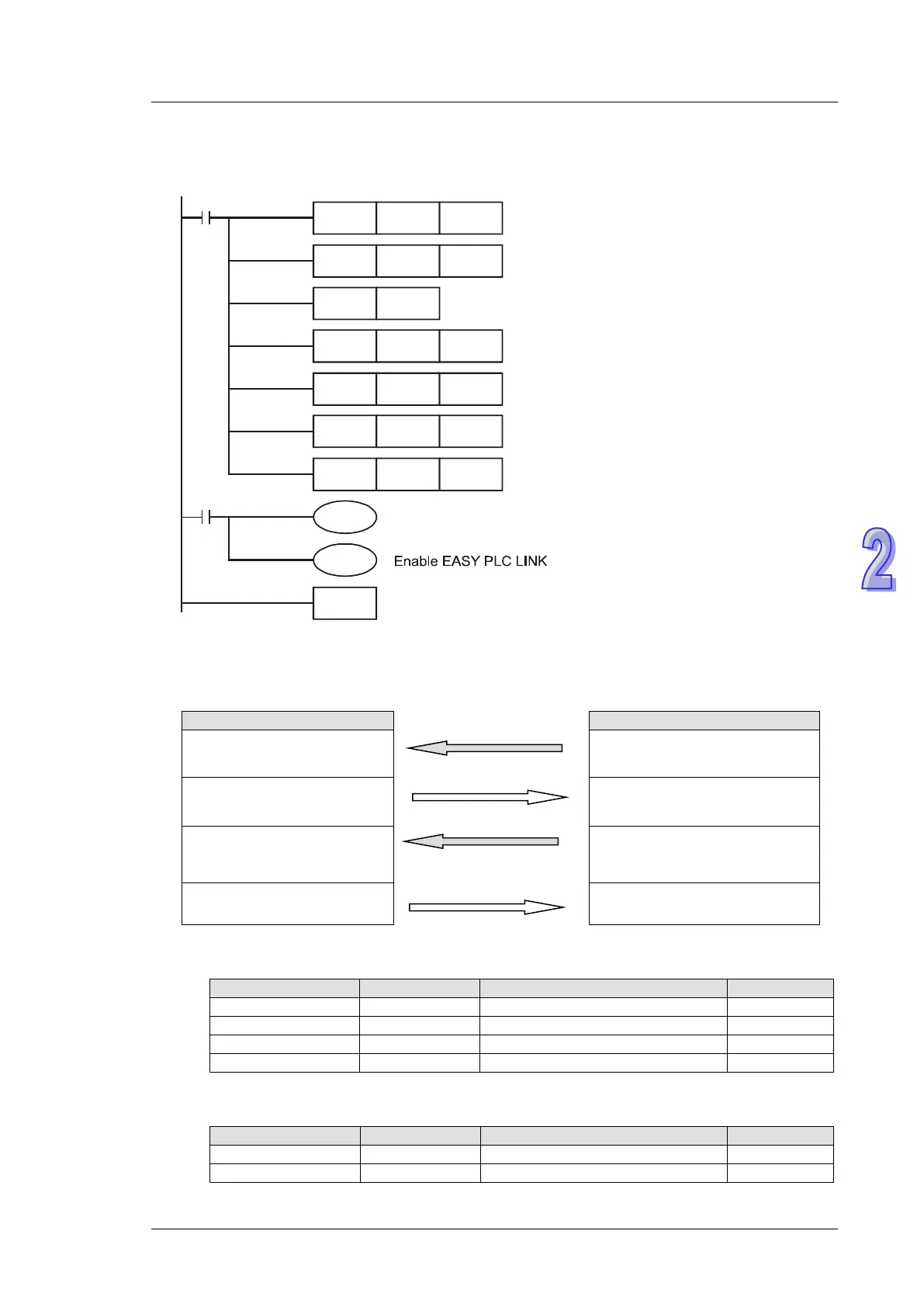

b) When X1 = On, the data exchange between Master and the two Slaves will be

automatically executed by PLC LINK. The data in D100 ~ D115 in the two Slaves will be

read into D1480 ~ D1495 and D1512 ~ D1527 of the Master, and the data in D1496 ~

D1511 and D1528 ~ D1543 will be written into D200 ~ D215 of the two Slaves.

D1480 ~ D1495

D100 ~ D115 of Connection

ID#1

D1496 ~ D1511

D200 ~ D215 of Connection

ID#1

D1512 ~ D1527

D100 ~ D115 of Connection

ID#2

D1528 ~ D1543

D200 ~ D215 of Connection

ID#2

c) Assume the data in registers for data exchange before enabling PLC LINK (M1350 = OFF)

is as below:

D100 ~ D115 of Connection ID#1

D200 ~ D215 of Connection ID#1

D100 ~ D115 of Connection ID#2

D200 ~ D215 of Connection ID#2

After PLC LINK is enabled (M1350 = ON), the data in registers for data exchange

becomes:

D100 ~ D115 of Connection ID#1

D200 ~ D215 of Connection ID#1

Loading...

Loading...