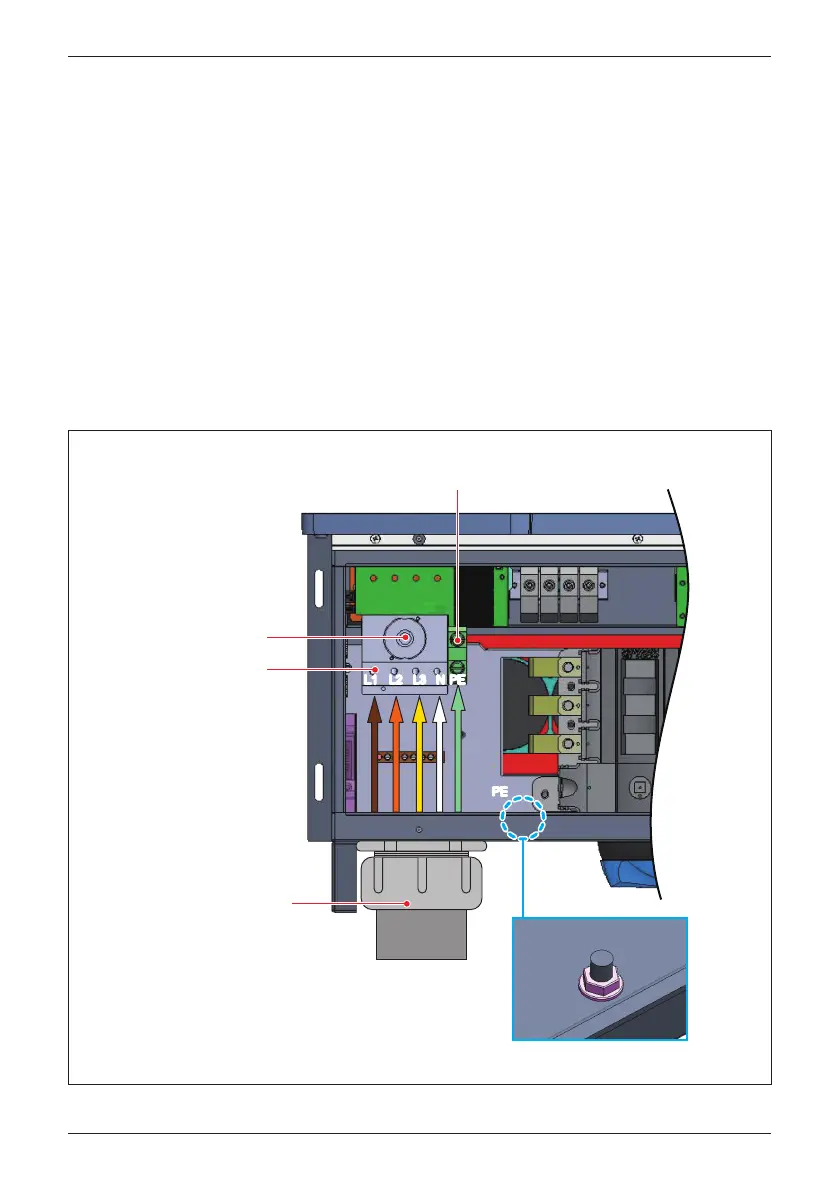

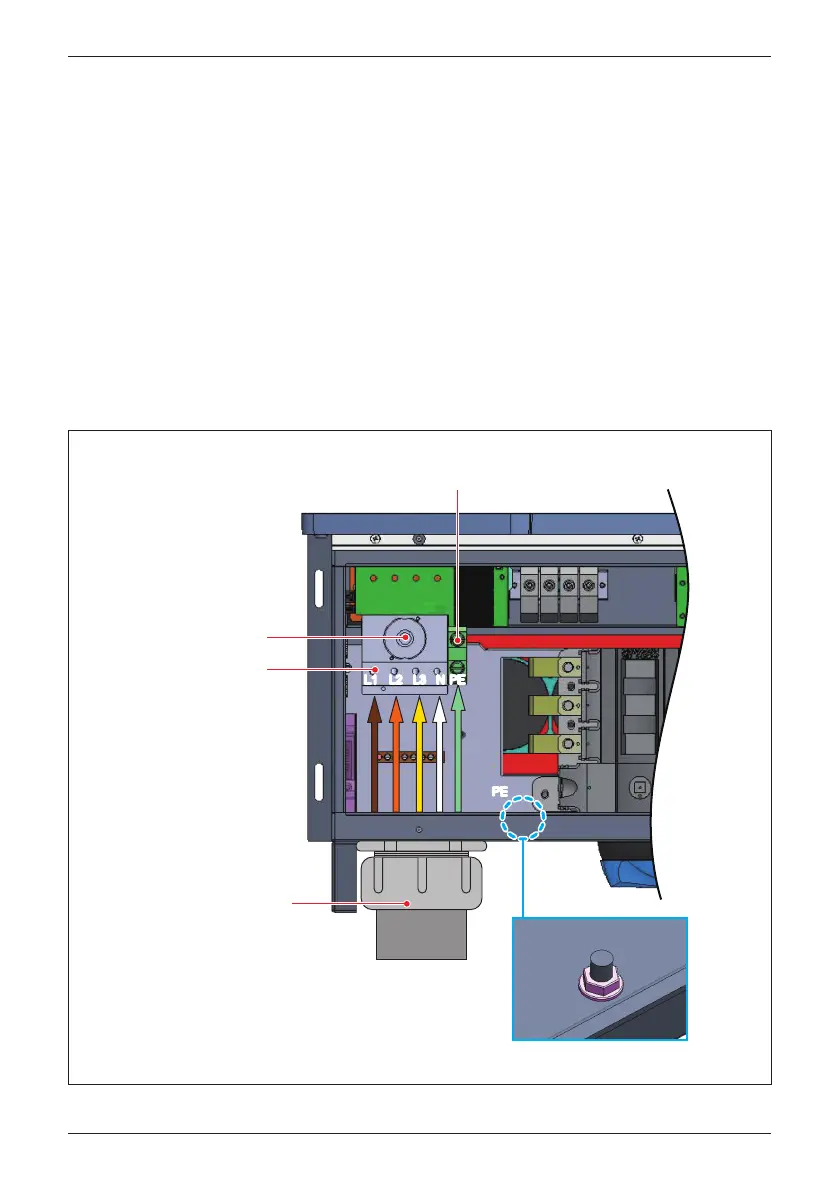

Figure 3-22: Two optional Locations for AC terminal (121 Model Without RSD)

After inserting conductor,

torque terminal screw to 49.5 lbf-in (5.6 N•m)

EMT

Bottom entry option using

2" (max) trade size raceway

After inserting conductor,

torque terminal screw to

31 lbf-in (3.5 N•m)

Refer to Figure 3-17 in Section 3.3 for the procedure to prepare AC conductors

for connection to the AC terminals (M80/60U

_121) :

Ensure the AC conductors used are sized to the correct ampacity per NEC or

other local code. Refer to Figure 3-17.

- Open all AC switch cage-clamps as noted in Section 3.3.4

- Ensure the correct conductor is connected to the appropriate terminal.

- After conductor is inserted, tighten L1~N terminal with a torque value of

31 lbf-in (3.5 N•m), PE terminal with 49.5 lbf-in (5.6 N•m).

- Insert the EGC (1~2/0 AWG) into the grounding screw terminal, torque value

of 80 lbf-in (9 N•m). (see Figure 3-22)

3.3.7

AC Wiring for M80/60U_121 models (Without RSD)

L3L2L1

NN PE

PE

AC switch

After inserting conductor,

torque terminal screw to 80 lbf-in (9 N•m)

Allowable PE conductor size 1~2/0 AWG (35~50mm²)

Grounding screw terminal

PEPE

45

Installation

Loading...

Loading...