12 Descriptions of Parameter Settings | VFD-ED

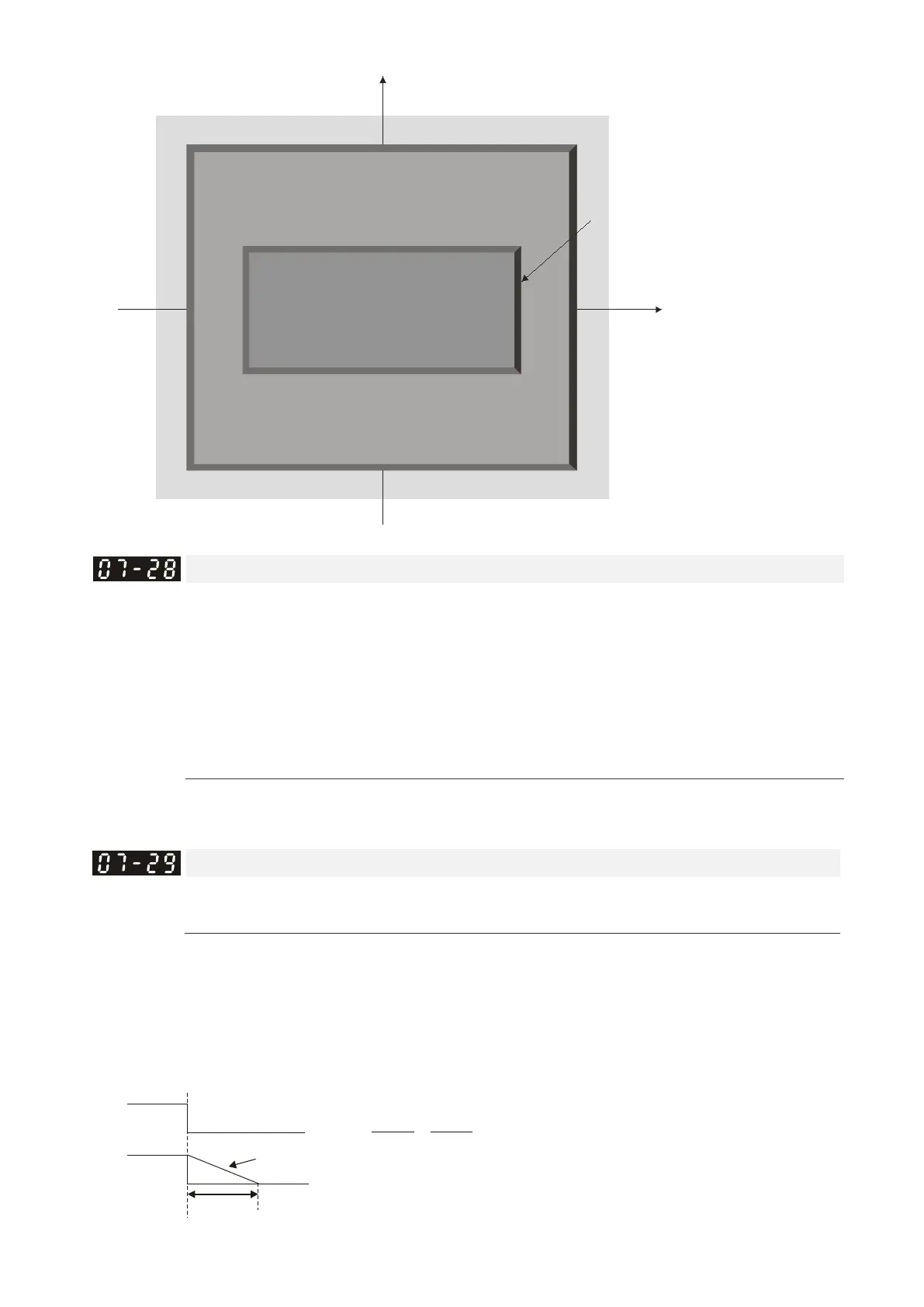

Positive

torque

Nega tive

torque

speed

06-1 1 current limit

06-1 1 current limit

06-1 1 current limit 06-1 1 current limit

Reverse motor mod e

Forward regenerative mode

Forward motor mode

Reverse rege nerative mode

The level o f torque limit will be

the min. va lu e of following three values

1. torq ue limit of Pr.07-24 to Pr.07-26

2. Torque limit of externa l analog terminals

3. Pr.06-11 curre nt limit

External analog terminals

Pr.03-00~02

7: positive torque limit

10: positive/negative torqu e limit

9: regenerative torque limit

External analog terminals

Pr.03-00~02

7: positive torque limit

10: positive/negative torque limit

External analog terminals

Pr.03-00~03-0 2

8: negative torque limit

10: positive/negative torqu e limit

External analog terminals

Pr.03-00~03-02

8: negative torque limit

9: Regenerative torque limit

10: positive/negative torque limit

Pr.07-27

Reverse rege nerative

torque limit

Pr.07-24

Forwa rd motor

torque limit

Pr.07-25

Forward regenerative

torque limit

Pr.07-26

Reverse motor

torque limit

Quadrant I

Quadrant II

Quadrant III

Quadrant IV

speed

Emergency Stop (EF) & Forced Stop

Control Mode

VF VFPG SVC FOCPG FOCPM

Default: 0

Settings 0: Coast to stop

1: According to deceleration Time 1

2: According to deceleration Time 2

3: According to deceleration Time 3

4: According to deceleration Time 4

5: According to Pr.01-31

When the multi-function input terminal is set to 10 or 18 and is ON, the drive operates according to this

parameter setting.

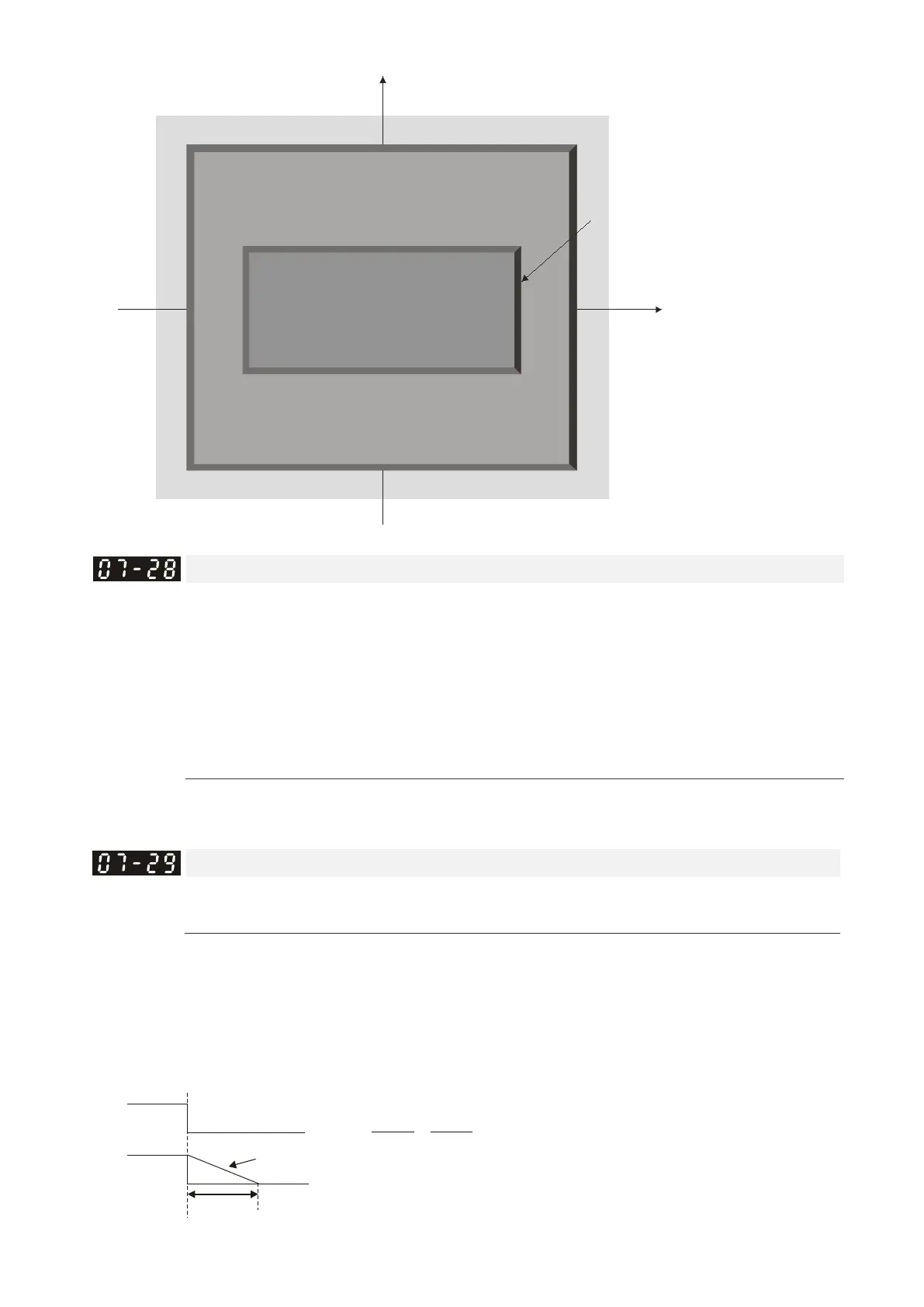

Time for Decreasing Torque at Stop

Control Mode

FOCPG FOCPM

Default: 0.000

Settings 0.000–5.000 sec.

When the elevator is stopped and the mechanical brake is engaged, the drive stops output. At the same

time, it produces noise from the reacting force between the motor and the mechanical brake. Use this

parameter to decrease this reacting force and lower the noise.

Sets the time when torque decreases from 300% to 0%.

RUN/STOP

0%

i

t

i

00-01

x

100%

300%

x

(07-29)=t

Loading...

Loading...