Chapter 12 Description of Parameter SettingsME300

12.1-06-12

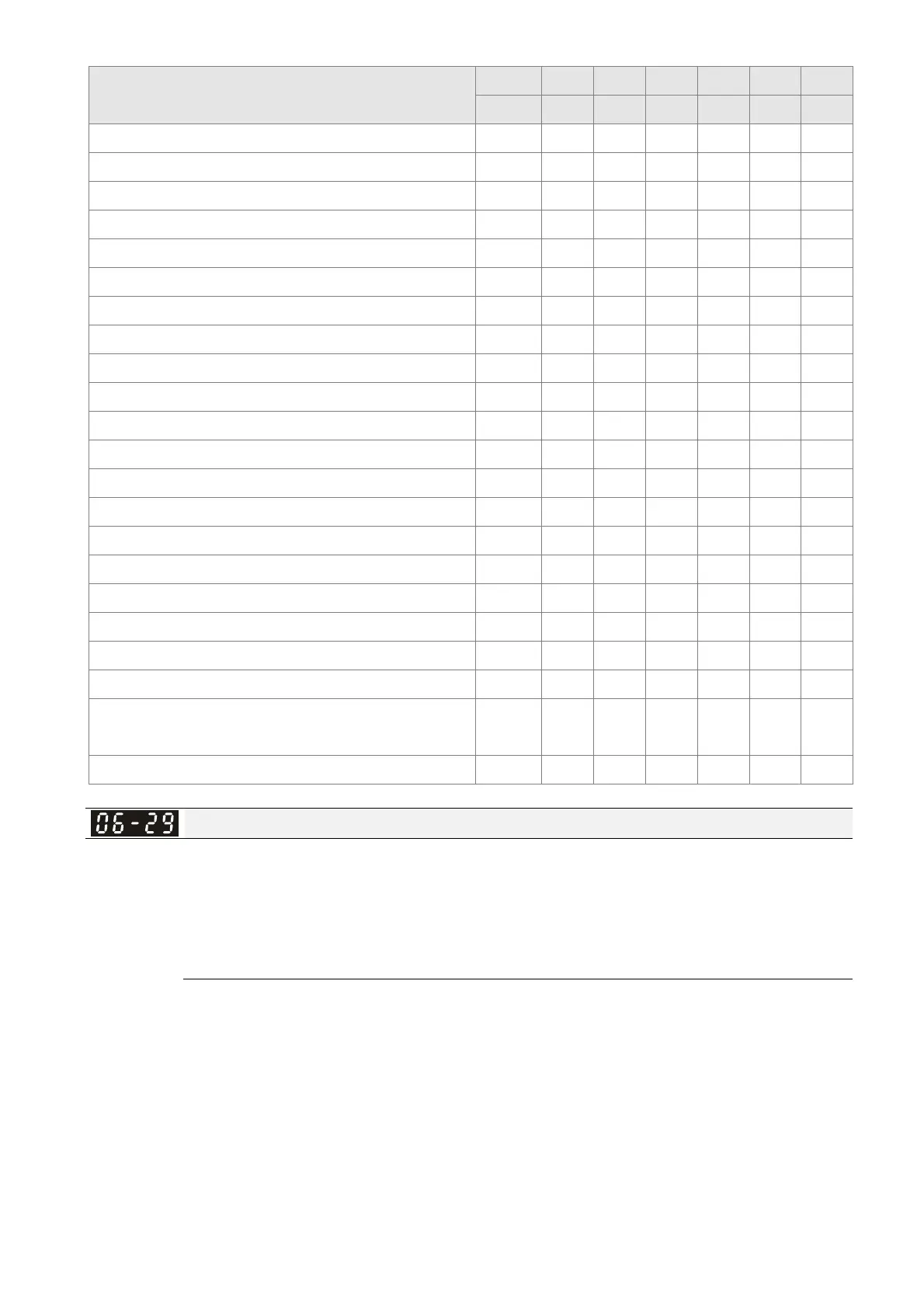

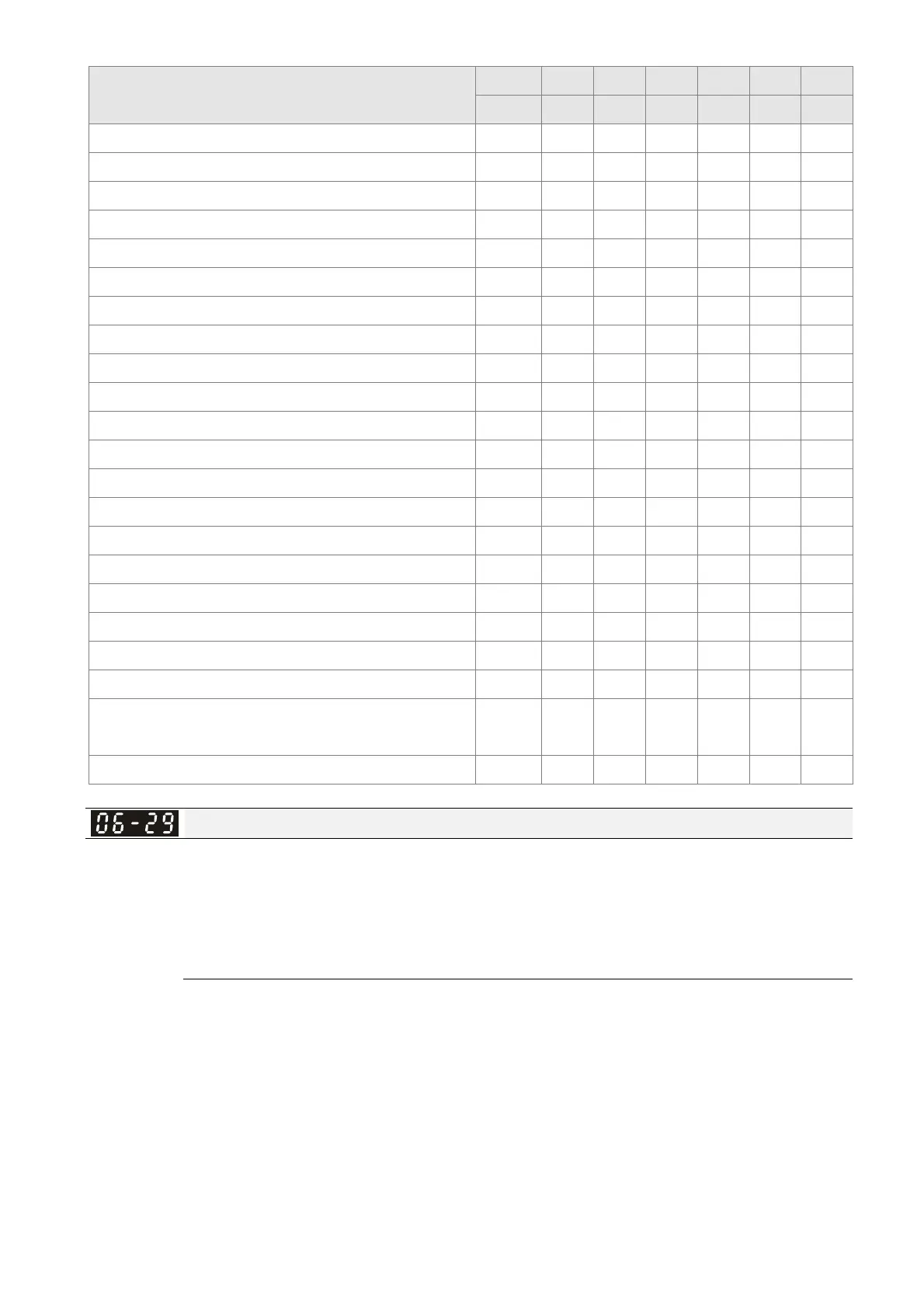

Fault Code

bit 0 bit 1 bit 2 bit 3 bit 4 bit 5 bit 6

current Volt. OL SYS FBK EXI CE

56: Communication error (CE3)

●

57: Communication error (CE4)

●

58: Communication time-out (CE10)

●

61: Y-connection/∆-connection switch error (ydc)

●

62: Deceleration Energy Backup Error (dEb)

●

72: Channel 1 (S1–DCM) safety loop error (STL1)

●

76: Safe Torque Off (STo)

●

77: Channel 2 (S2–DCM) safety loop error (STL2)

●

78: Internal loop error (STL3)

●

79: U-phase over-current before run (Uoc)

●

80: V-phase over-current before run (Voc)

●

81: W-phase over-current before run (Woc)

●

82: U-phase output phase loss (OPHL)

●

83: V-phase output phase loss (OPHL)

●

84: W-phase output phase loss (OPHL)

●

87: Drive overload in low frequency (oL3)

●

89: Initial rotor position detection error (RoPd)

●

140: GFF detected when power on (Hd6)

●

141: GFF before run (BGFF)

●

142: Auto-tuning error 1 (DC test stage) (AUE1)

●

143: Auto-tuning error 2 (High frequency test stage)

(AUE2)

●

144: Auto-tuning error 3 (Rotary test stage) (AUE3)

●

PTC Detection Selection

Default: 0

Settings 0: Warn and continue operation

1: Warn and ramp to stop

2: Warn and coast to stop

3: No warning

Sets the operation mode of a drive after you set Pr.06-29 to define PTC detection.

Running a motor at low frequency for a long time reduces the cooling function of the motor fan. To

prevent the motor from damage due to overheating, use a Positive Temperature Coefficient

thermistor on the motor, and connect the thermistor output signal to the drive’s analog input

terminals.

Loading...

Loading...