NO.6 Detailed Function Description

57

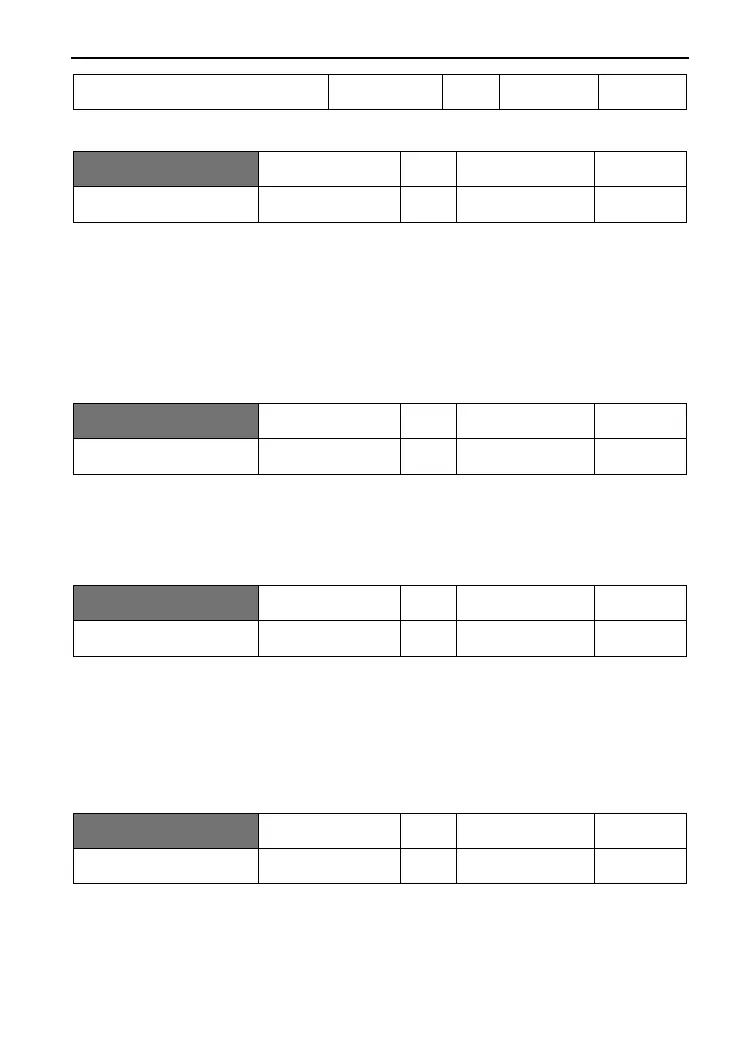

Stall level during deceleration

Please refer to P120 description.

Selection of over torque

detection method

0: While achieving the frequency, start to detect over torque; after the detection of over

torque, continue operating.

1: While achieving the frequency, start to detect over torque; after the detection of over

torque, stop operating.

2: Detect the over torque during running; after the detection of over torque, continue

operating.

3: Detect the over torque during operating; after the detection of over torque, stop operating.

Over torque

detection level

When output current goes beyond torque detection level and exceeds half of set time value

(ex-factory value 1.0s), over torque detection shall be indicated and corresponding

multi-function alarm contact shall be actuated; when it exceeds set time value, the inverter

shall provide protection, and when this parameter is set to 0, over torque shall not be

detected.

Over torque

detection time

When the inverter detects that output current exceeds set motor current, it shall start to

calculate over torque time; when over torque time goes beyond half of set detection time

value, corresponding multi-function output terminal shall be actuated with over torque alarm,

and the inverter continue operating. In case that over torque time exceeds set detection time

value (P125 setting), the inverter shall provide protection, failure information be displayed

and the inverter stop outputting.

Refer to P123 and P124 for relevant parameters.

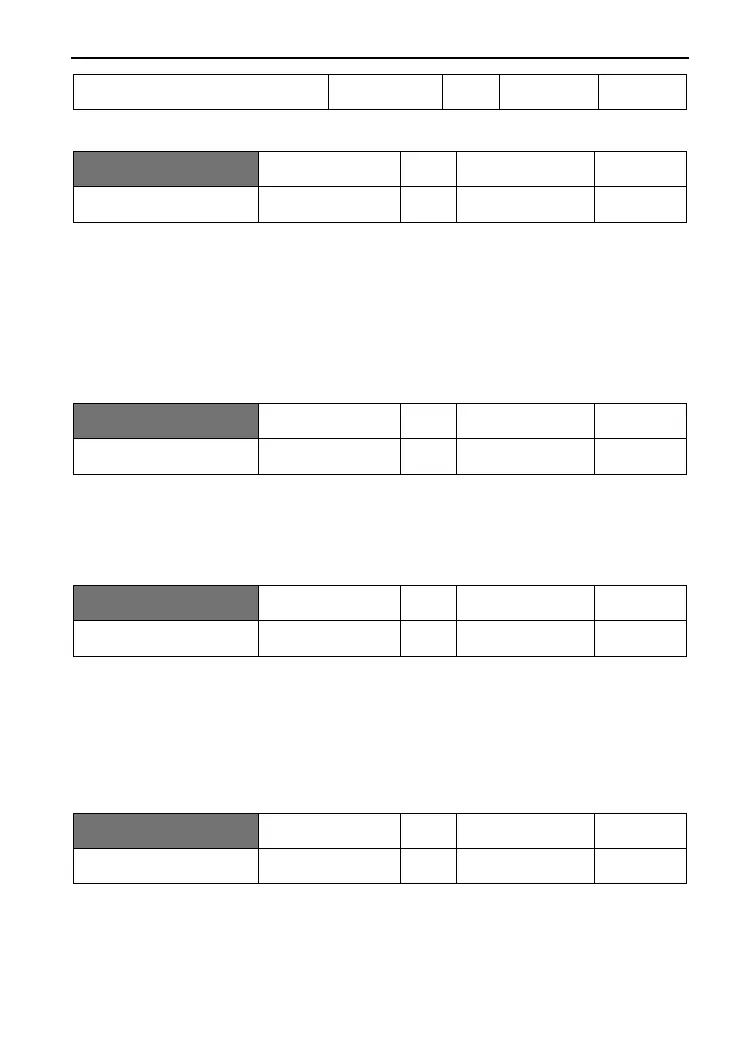

0: Not memorized 1: Memorized

Determine whether to memorize counter values after power failure of the inverter via memory

function of pulse counter.

Loading...

Loading...