D1000 Installation and Service Manual 21

Home LAB-110073 Rev. 3

DUCTING AND AIRFLOW

The ductwork and fittings used for outside venting must be carefully selected to ensure that the static pressure is in line

with the fan parameters. The ducting is provided by other and should be specified by the HVAC contractor on the job as

each local code requirement may differ.

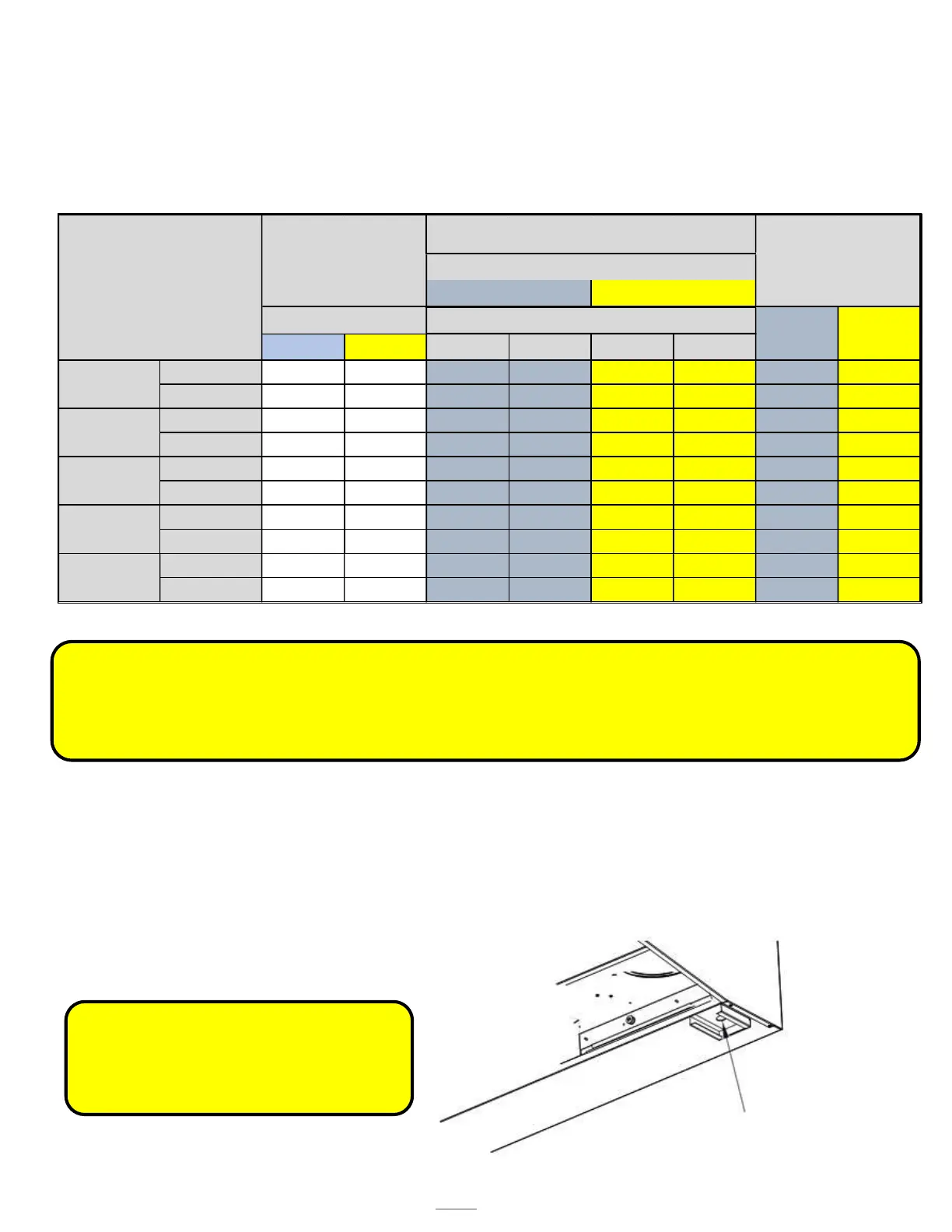

The recommended duct length for all “D” models, allows for up to three 90 angles. The table below are readings tested

at 25’ of duct work where applicable.

STATIC PRESSURE TESTING

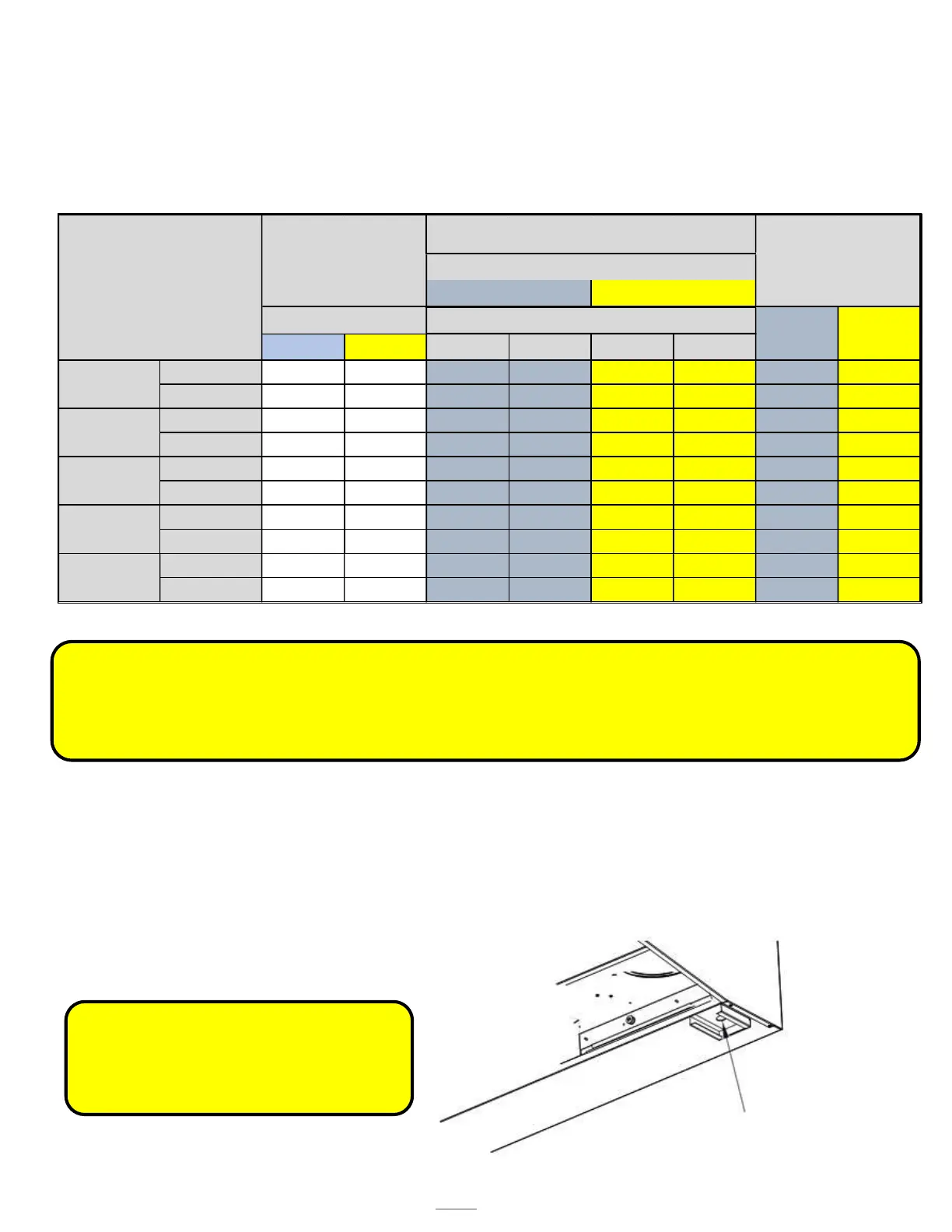

The magnehelic gauge test port opening is located beneath the grease tray. The static pressure needs to be measured to

ensure air flows meet design criteria. The airflow is measured by attaching the gauge tubing to the magnehelic gauge

inlet, and the hood fitting is attached to the grease drain hole beneath the grease tray.

Refer to chart above to meet design standards. This reading will correspond to the static pressures of the ductwork, hood

and fan combination.

Low High Without With Without With

Standard 62 70 -0.01 -0.09 -0.02 -0.18 174 276

NFPA 60 84 -0.04 -0.26 -0.23 -1.38 216 514

Standard 62 70 -0.01 -0.09 -0.01 -0.17 139 279

NFPA 60 80 -0.03 -0.25 -0.17 -1.35 174 519

Standard 57 69 -0.03 -0.23 -0.11 -0.61 283 474

NFPA 60 70 -0.05 -0.29 -0.20 -0.89 297 545

Standard 56 60 -0.02 -0.14 -0.05 -0.28 208 281

NFPA 60 75 -0.01 -0.10 -0.11 -0.66 172 522

Standard 61 73 -0.07 -0.40 -0.14 -0.84 357 499

NFPA 63 75 -0.08 -0.39 -0.22 -1.09 326 548

CFM

(+ - 2.5%)

Low High

Fan Speed

Grease Filter

Front

Rear

In-line

Wall Mount

Roof Mount

dB's

PRESSURE (InWater)

Fan Speed

Low High

Figure 14.12 Magnehelic

Gauge Test Port

WARNING: The static pressure must be

maintained in order for the hood to perform

properly. The grease filter must be in place

when performing the reading.

WARNING: The amount of fittings and ductwork directly a

ects the resistance or static pressure placed on the system. If

the system is not within the proper static pressure range, the heat sensors and controls will be adversely a

ected and will

impact the proper functioning of the safety controls. Therefore it is required that air flow testing be recorded along with

install documentation. The air testing area is accessed by the removal of the grease tray and measured with an air flow

pressure gauge.

Loading...

Loading...