Operation Section

1

–

33

(3) Injection Timing Calculation Method

11.3 Microinjection Quantity Learning Control

(1) Outline

• Quantity learning control is used in every vehicle engine (injector) to preserve the accuracy of quantity (specifically, pilot injection

quantity.)

This type of control is first performed when shipped from the factory (L/O), and later is automatically performed every time the vehicle

runs a set distance (for details, see item "A".) Because of quantity learning control, the accuracy of each injector can be preserved not

only initially, but also as deterioration in injection occurs over time. As a result of this learning, correction values are recorded in the

ECU. During normal driving operations, this correction value is used to make modifications to injection commands, resulting in ac-

curate microinjection.

(2) Learning Operations

• For every two no load, idle instability conditions established (See chart "A" below) quantity learning takes place.

In addition, it is also possible to perform quantity learning control manually as a diagnostic tool.

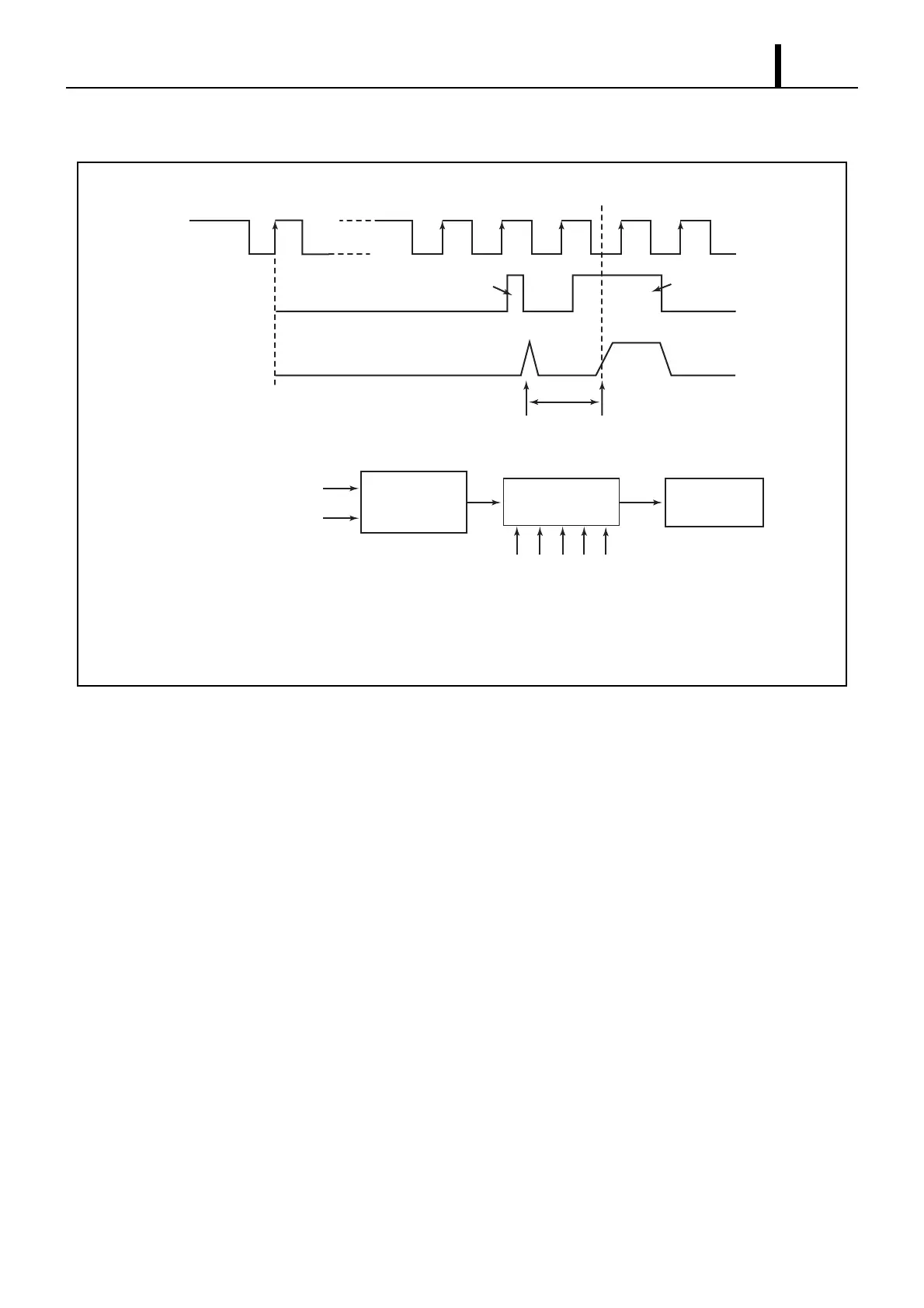

NE Pulse

Solenoid Valve Control Pulse

Nozzle Needle Lift

01

Actual TDC

Main Injection

Pilot Injection

Pilot Injection Timing

Main Injection Timing

Pilot Interval

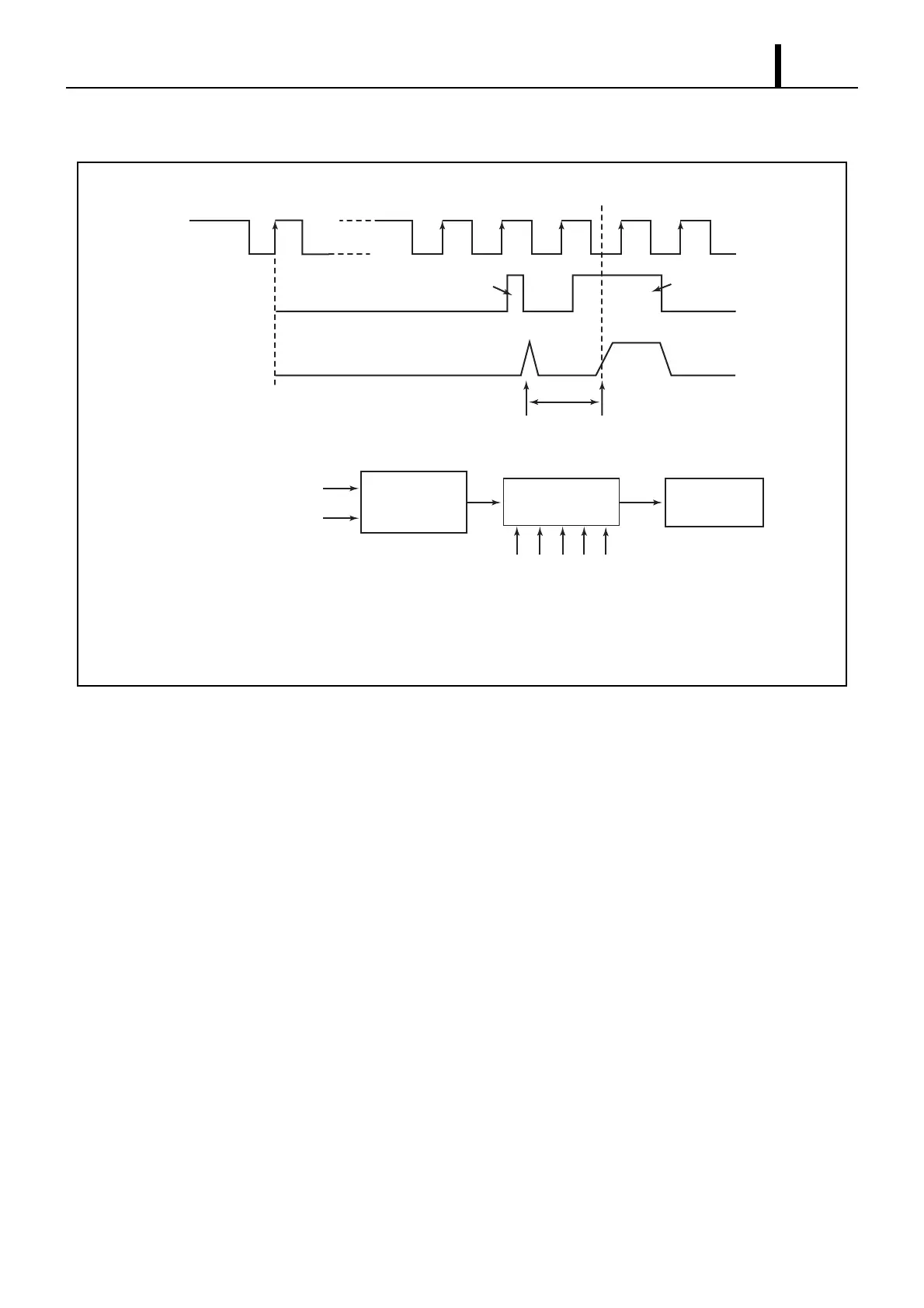

Basic Injection

Timing

Corrections

Engine Speed

Injection Quantity

Main Injection

Timing

Atmospheric Pressure Correction

Coolant Temperature Correction

Intake Air Temperature Correction

Intake Air Pressure Correction

[1] Outline of Timing Control

[2] Injection Timing Calculation Method

QB0724E

Voltage Correction

Loading...

Loading...