Operation Section

1

–

2

2. OUTLINE OF SYSTEM

2.1 Common Rail System Characteristics

z The common rail system uses a type of accumulation chamber called a rail to store pressurized fuel, and injectors that contain elec-

tronically controlled solenoid valves to inject the pressurized fuel into the cylinders. Because the engine ECU controls the injection

system (injection pressure, injection rate, and injection timing), the injection system is independent, and thus unaffected by the engine

speed or load. This ensures a stable injection pressure at all times, particularly in the low engine speed range, and dramatically de-

creases the amount of black smoke ordinarily emitted by a diesel engine during start-up and acceleration. As a result, exhaust gas emis-

sions are cleaner and reduced, and higher power output is achieved.

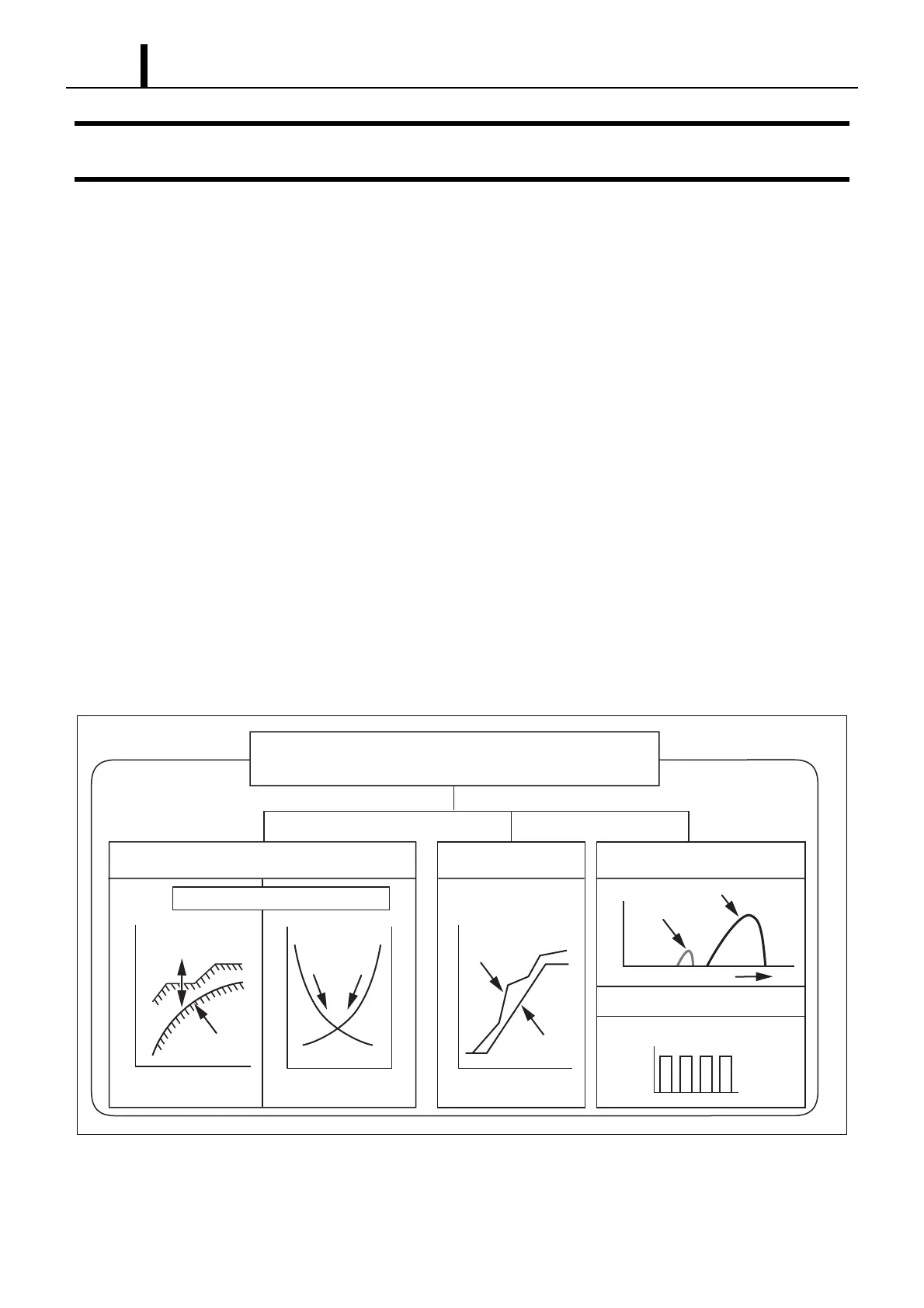

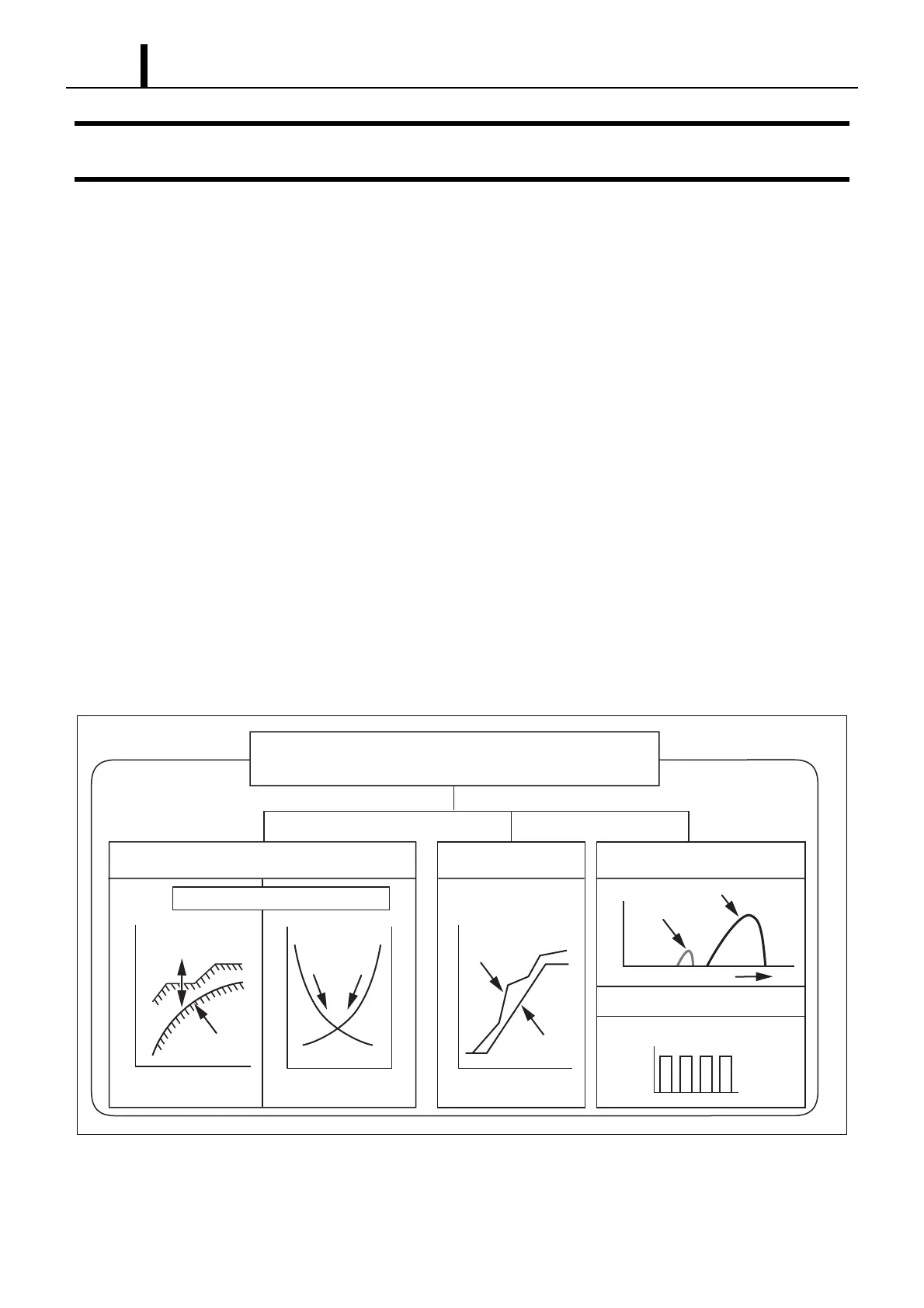

2.2 Features of Injection Control

(1) Injection Pressure Control

• Enables high-pressure injection even at low engine speeds.

• Optimizes control to minimize particulate matter and NOx emissions.

(2) Injection Timing Control

• Enables finely tuned optimized control in accordance with driving conditions.

(3) Injection Rate Control

• Pilot injection control injects a small amount of fuel before the main injection.

Q001223E

Common Rail System

Injection Pressure Control

Injection Timing Control

Injection Rate Control

Optimization, High Pressurization

Common Rail

System

Conventional

Pump

Conventional

Pump

Speed

Speed

Injection Pressure

Optimization

Common Rail

System

Particulate

NOx

Injection Timing

Speed

Injection Quantity Control

Cylinder Injection

Quantity Correction

Pre-Injection

Main Injection

Crankshaft Angle

Injection Rate

Injection Pressure

1

3 4

2

Loading...

Loading...