Operation Section

1

–

26

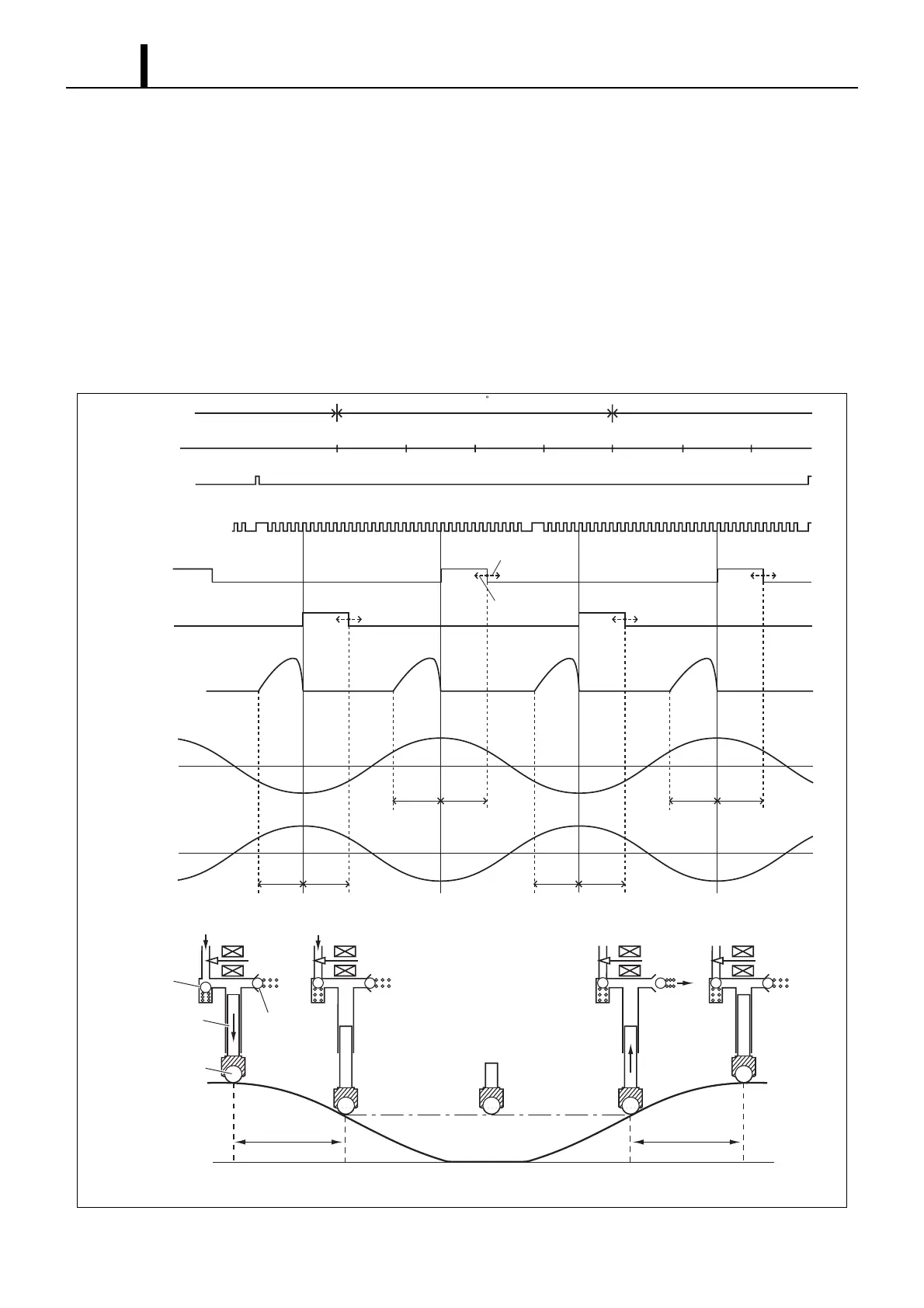

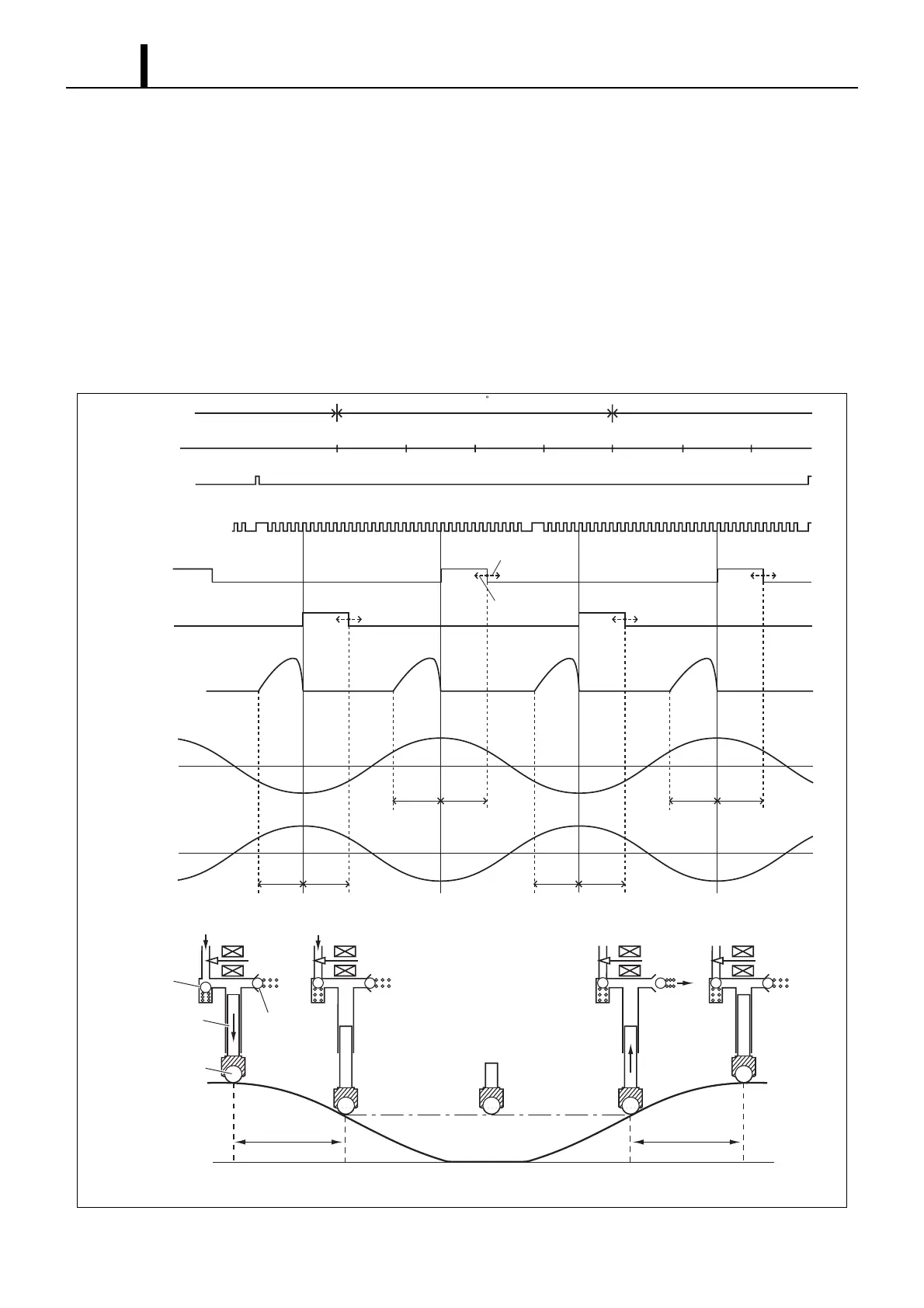

Fuel Discharge Quantity Control

• The diagram below shows that the suction starting timing (SCV (Suction Control Valve) ON) is constant (determined

by the pump speed) due to the crankshaft position sensor signal. For this reason, the fuel suction quantity is controlled

by changing the suction ending timing (SCV OFF). Hence, the suction quantity decreases when the SCV is turned

OFF early and the quantity increases when the SCV is turned OFF late.

• During the intake stroke, the plunger receives the fuel feed pressure and descends along the cam surface. When the

SCV turns OFF (suction end), the feed pressure on the plunger ends and the descent stops. Since the suction quantity

varies, when suction ends (except for maximum suction) the roller separates from the cam surface.

• When the drive shaft rotates and the cam peak rises and the roller comes in contact with the cam surface again, the

plunger is pressed by the cam and starts pumping. Since the suction quantity = the discharge quantity, the discharge

quantity is controlled by the timing with which the SCV is switched OFF (suction quantity).

0 2 4 6 8 101214 16 0 2 4 6 8 101214 0 2 4 6 8 101214 16 0 2 4 6 8 101214

Suction Suction

Suction Suction

Decreased Suction

Quantity

Increased Suction

Quantity

ON

OFF

SCV 1

SCV 2

Suction Pumping

Start of Suction End of Suction Start of Pumping End of Pumping

360 CR

TDC #1

TDC #3 TDC #4

TDC #2

Cylinder Recognition

Sensor Signal

Crankshaft Position

Sensor Signal

ON

OFF

Crankshaft

Angle

Compression

Top Dead Center

Fuel

ON

Plunger

Roller

OFF

Fuel

OFF

Fuel

OFF

Delivery Valve

Discharge

Horizontal

Cam Lift

Vertical

Cam Lift

Check Valve

SCV

Pumping

Suction

Pumping

Suction

Pumping

Suction

Pumping

Suction

Delivery Valve

Q000833E

Loading...

Loading...