Operation Section

1

–

88

9.3 Higher Injection Pressure, Optimized Injection Rates, Higher Injection

Timing Control Precision, Higher Injection Quantity Control Precision

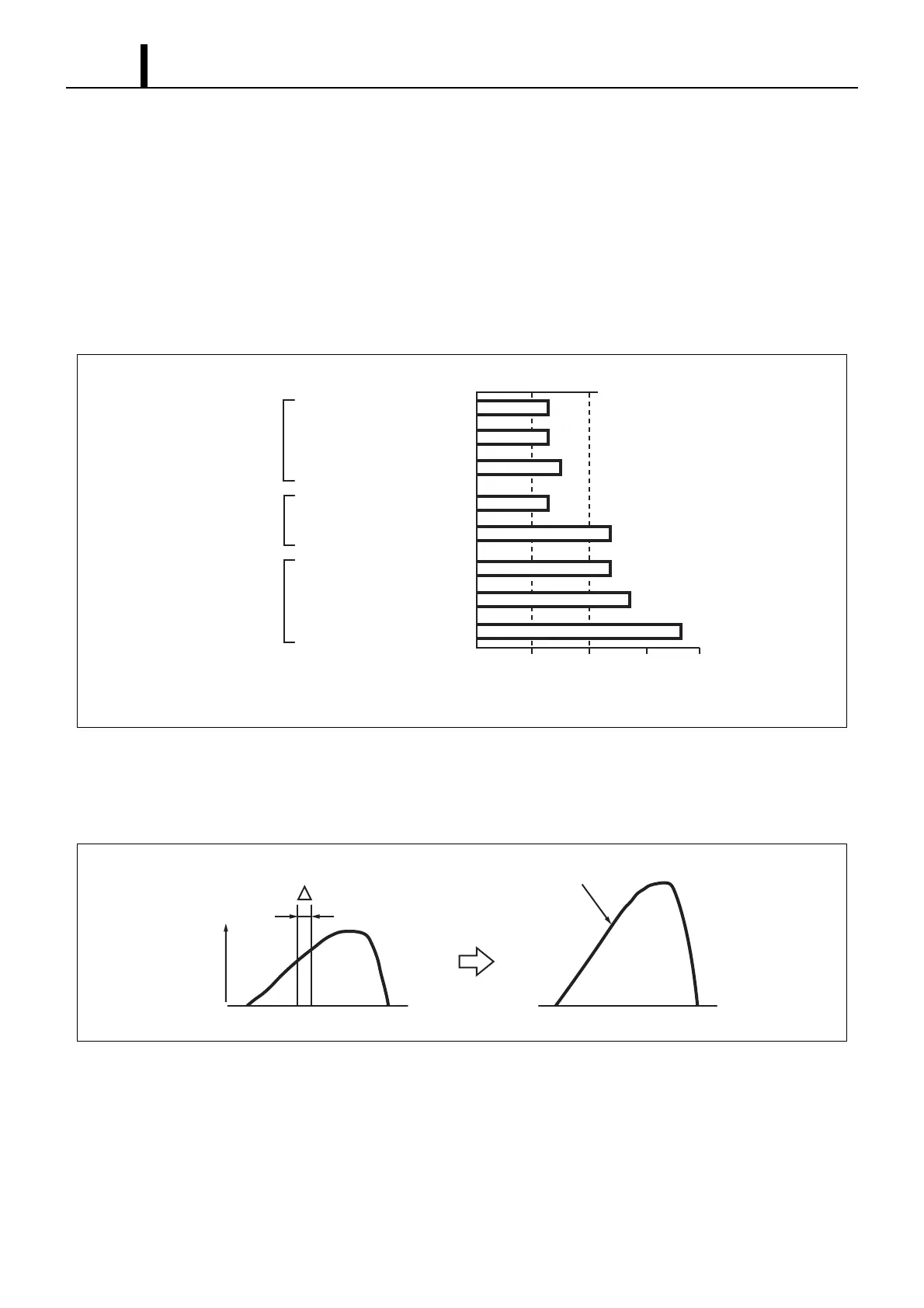

(1) Higher Injection Pressure

• The fuel that is injected from the nozzle turns into finer particles as the fuel injection pressure increases. This improves

combustion and reduces the amount of smoke contained in the exhaust gases. Initially, the maximum injection pres-

sure of the in-line pump (A type) and the distributor pump (VE type) was 60 MPa. Due to advancement in high-pres-

sure applications, there are some recently developed fuel injection systems that inject fuel at a pressure of 100 MPa

or higher. The second-generation common rail system injects fuel at an extremely high pressure of 180 MPa.

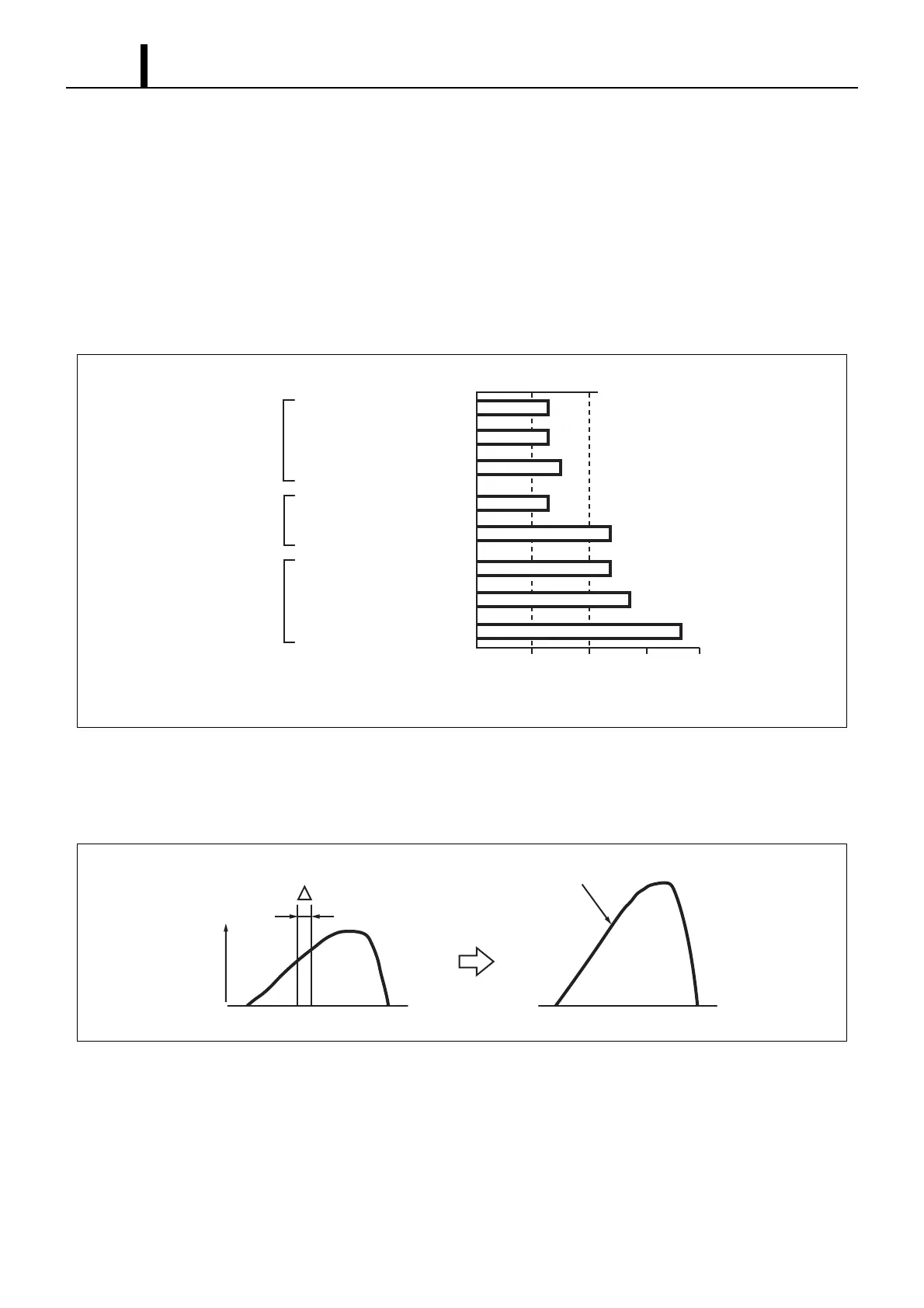

(2) Optimized Injection Rates

• The injection rate is the ratio of the changes in the fuel quantity that is injected successively from the nozzle within a

given unit of time.

Q000920E

50

Common Rail Series

100 150 200

185

145

120

120

ECD V Series

Mechanical Pump

Injection Pressure

(

MPa

)

A Type Pump

Distributor Type Pump

NB Type Pump

ECD V4 Pump

HP0Pump

HP2Pump

HP3,4Pump

ECD V3 Pump

(1st Generation)

(2nd Generation)

1 MPa is

approximately 10.2kgf/cm

2

t

Injection Rate

High Injection Rate

Injection Quantity

Q000921E

Loading...

Loading...