Operation Section

1

–

89

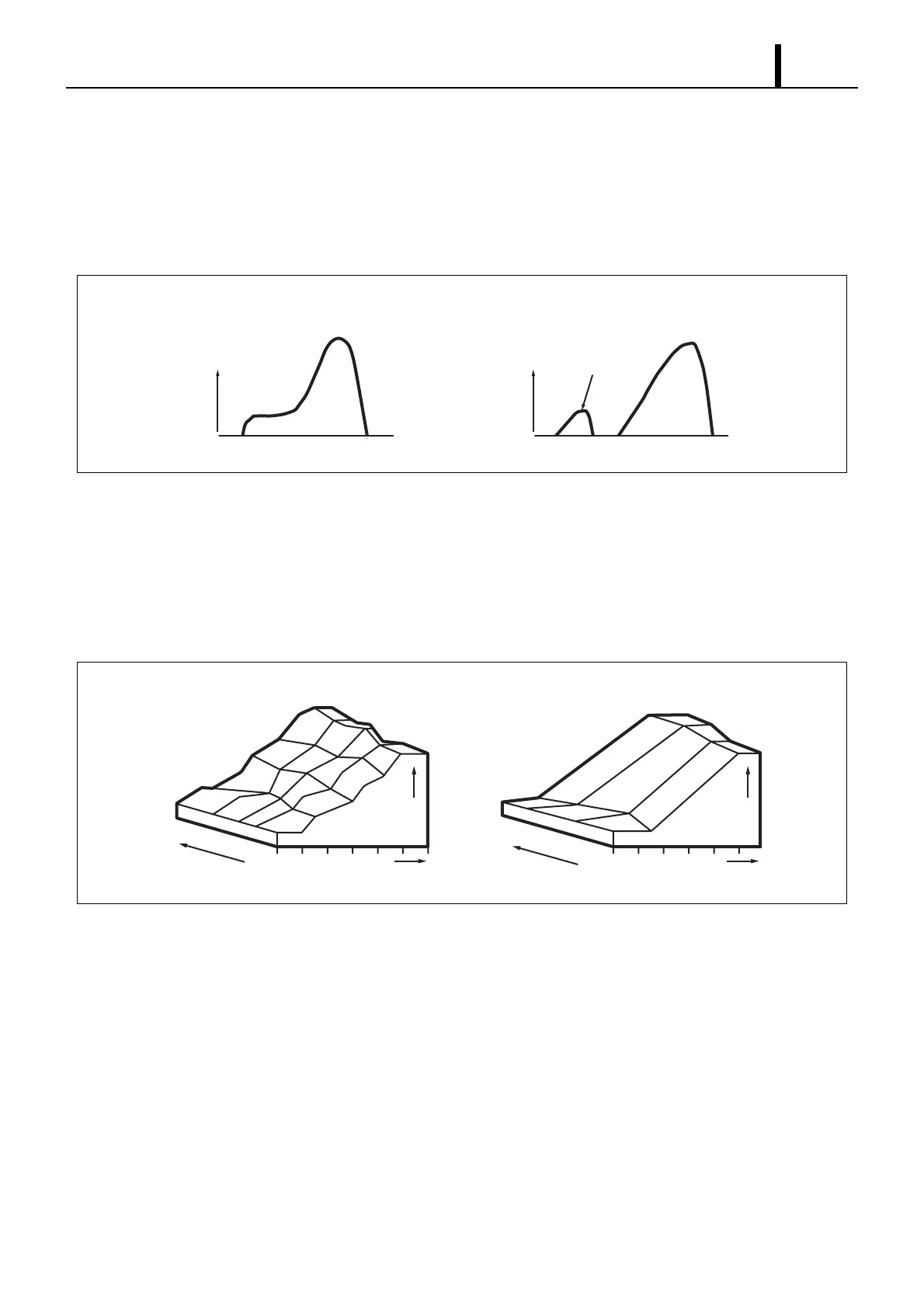

• As the injection pressure increases, the injection rate increases accordingly. The increase in injection rate leads to an

increase in the volume of the air-fuel mixture that is created between the start of injection until ignition (the ignition lag

period). Because this mixture is subsequently combusted at once, it creates noise (diesel knock) and NOx. For this

reason, it is necessary to appropriately control the injection rate by maintaining a low injection rate at the beginning

of injection and supplying a sufficient quantity after the ignition. To meet this need, two-spring nozzles have been

adopted and a pilot injection system has recently been developed.

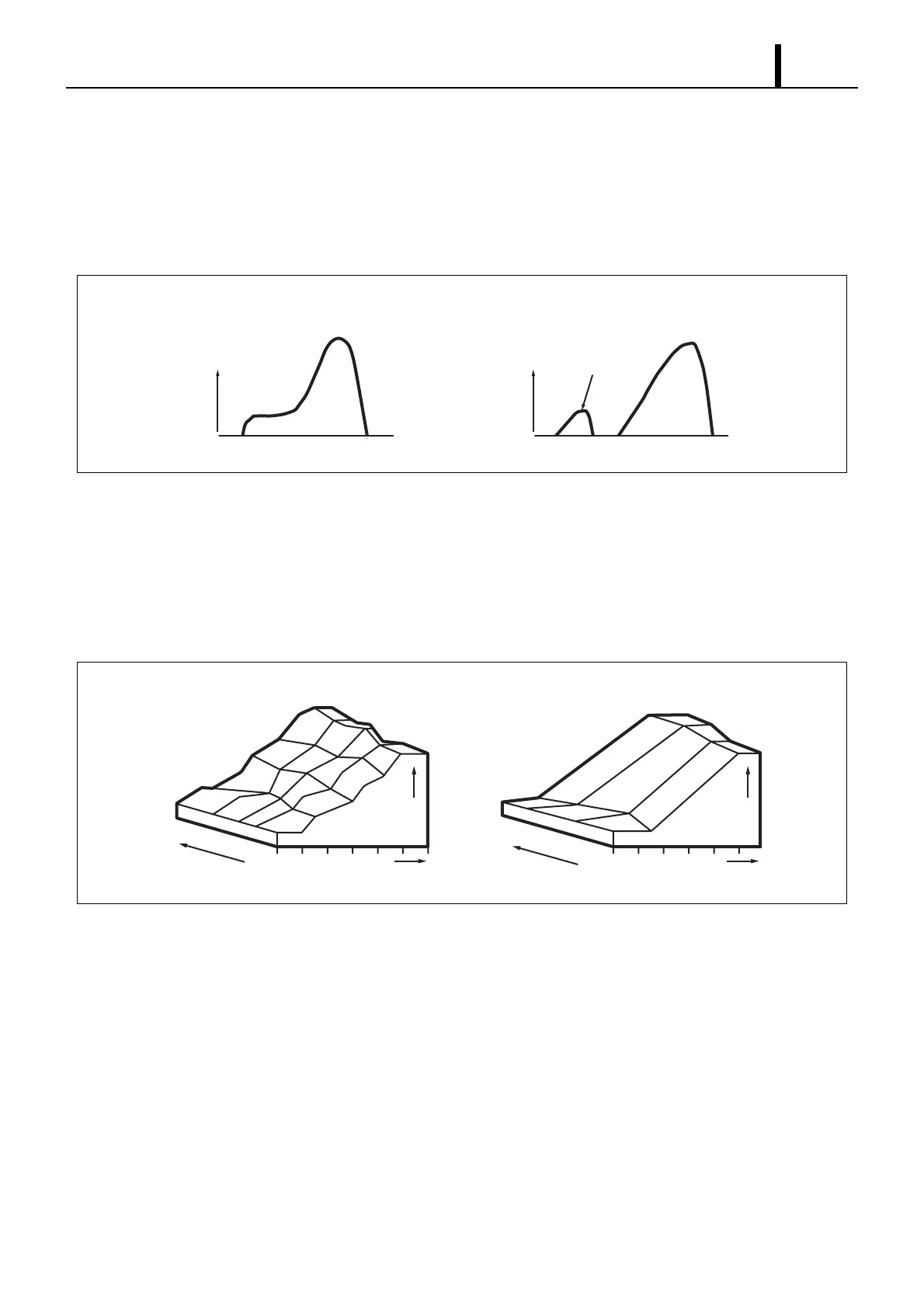

(3) Higher Injection Timing Control Precision

• Reducing exhaust gas emissions and fuel consumption and optimizing the injection timing are important. It is ex-

tremely difficult to achieve the desired exhaust emission reduction levels through methods that adjust the injection

timing according to speed (or centrifugal force), such as the conventional mechanical timer. For this reason, electron-

ically controlled systems have been adopted to freely and precisely control the injection timing in accordance with the

engine characteristics.

(4) Higher Injection Quantity Control Precision

• Power output adjustment in a diesel engine is accomplished by regulating the fuel injection quantity. Poor injection

quantity control precision leads to increased exhaust gas emissions, noise, and poor fuel economy. For this reason,

electronically controlled systems have been developed to ensure high precision injection quantity control.

2-Spring Nozzle

Injection Rate

Common Rail System

Injection Rate Control

Injection Quantity

Injection Quantity

Pilot Injection

Q000922E

Electronic Control Type Mechanical Timer

Engine Speed Engine Speed

Injection Quantity

Injection Quantity

Advance

Angle

Advance

Angle

Q000923E

Loading...

Loading...