24

GASOLINE CHAIN SAW

EN

EN

A special holder with a 4 mm round le should be used for sharpening. Regular round les are not suitable for

sharpening. The sharpening should only be done with the le moving forward (in the direction of the arrow).

If the le is moved backwards, the pressure on the tool should be reduced (g. 33).

min

3 мм (0.11˝)

a

a

a

0,64 mm

(0.025˝)

0,64 mm

(0.025˝)

90°

85˚ 85˚

30˚

30˚

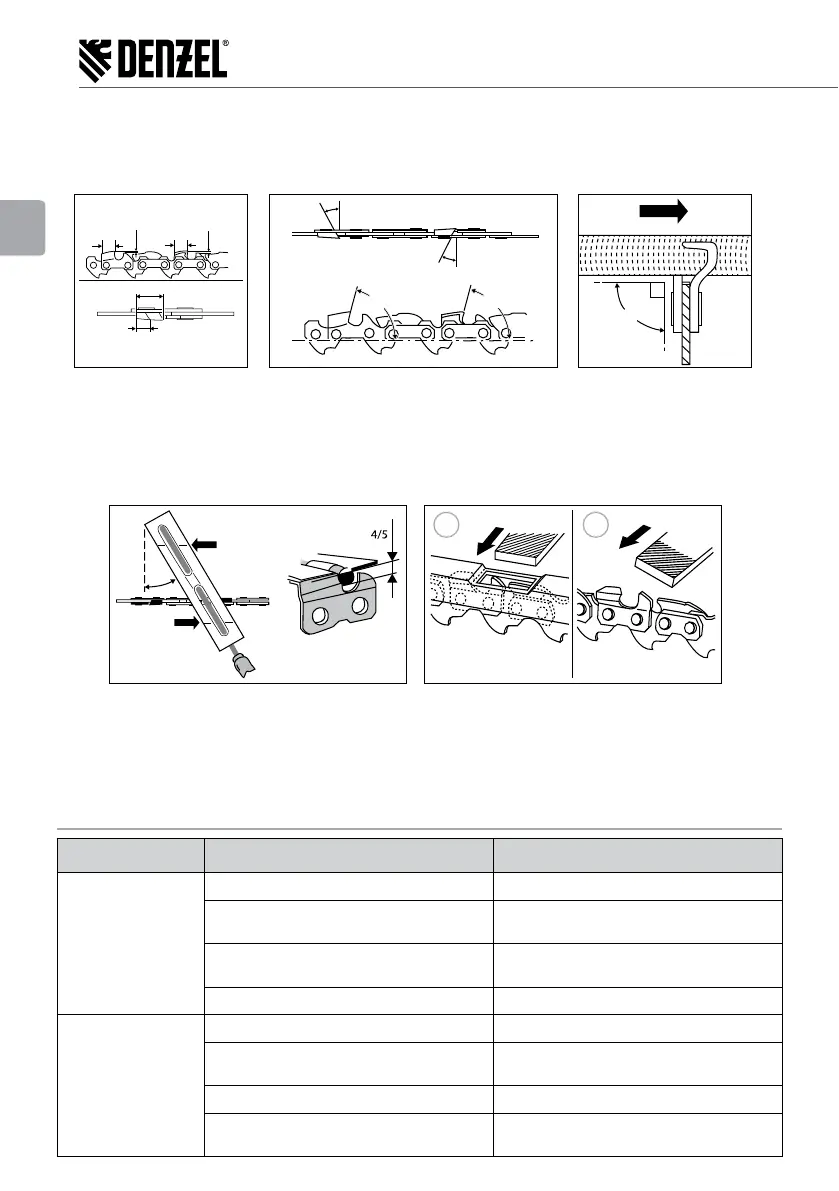

Fig. 31 Fig. 32 Fig. 33

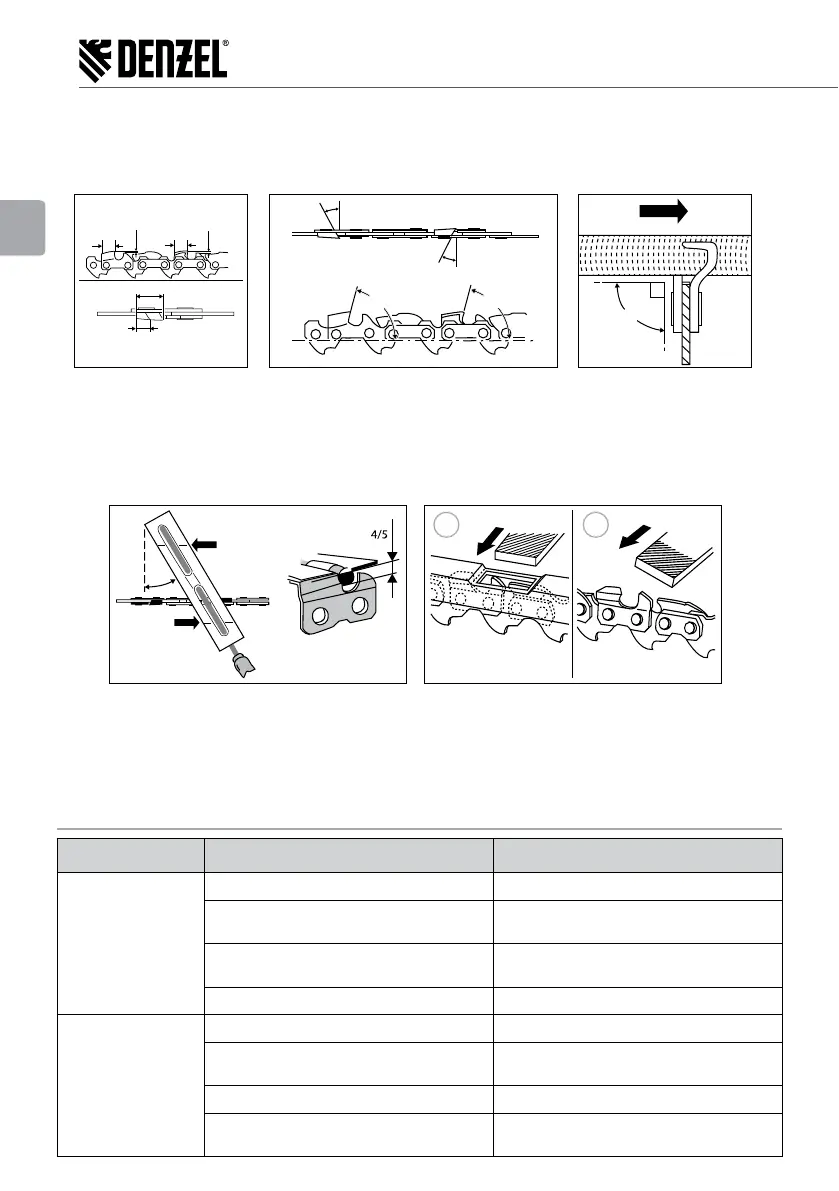

First the shortest saw tooth is sharpened. Its length is the target length for sharpening all other teeth of the

saw chain. Guide the le as shown in the illustration. The le holder makes it easier to guide the le during

sharpening and has a marking for the correct 30° sharpening angle (align the marking with the direction

of the saw chain). It limits the penetration depth (4/5 of the le diameter) (g. 34).

30º

21

Fig. 34 Fig. 35

Even a slight excess of the depth gauge tooth should be ground down with a special at le. The depth gauge

should be rounded at the front.

At the end of the sharpening process, the height of the depth stop should be checked with a chain gauge (g. 35).

POSSIBLE MALFUNCTIONS AND TROUBLESHOOTING METHODS

Problem Possible reason Corrective action/s

Engine does not start.

Violation of start-up procedures. Follow the instructions in manual.

Incorrect carburettor setting.

Adjust the carburettor at an authorized service

center.

Dirty spark plug.

Clean spark plug/adjust clearance or replace

spark plug.

Fuel lter plugging. Replace the fuel lter.

Saw starts, but motor

runs with low power.

Incorrect position of the air damper control. Adjust the air damper.

Dirty spark plug.

Clean spark plug/adjust clearance or replace

spark plug.

The air lter is dirty. Remove, clean and reinstall the lter.

Incorrect carburettor adjustment.

Adjust the carburettor at an authorized service

center.

Loading...

Loading...