EN - 7

A-535D

iFill Oxygen Cylinder/Regulator

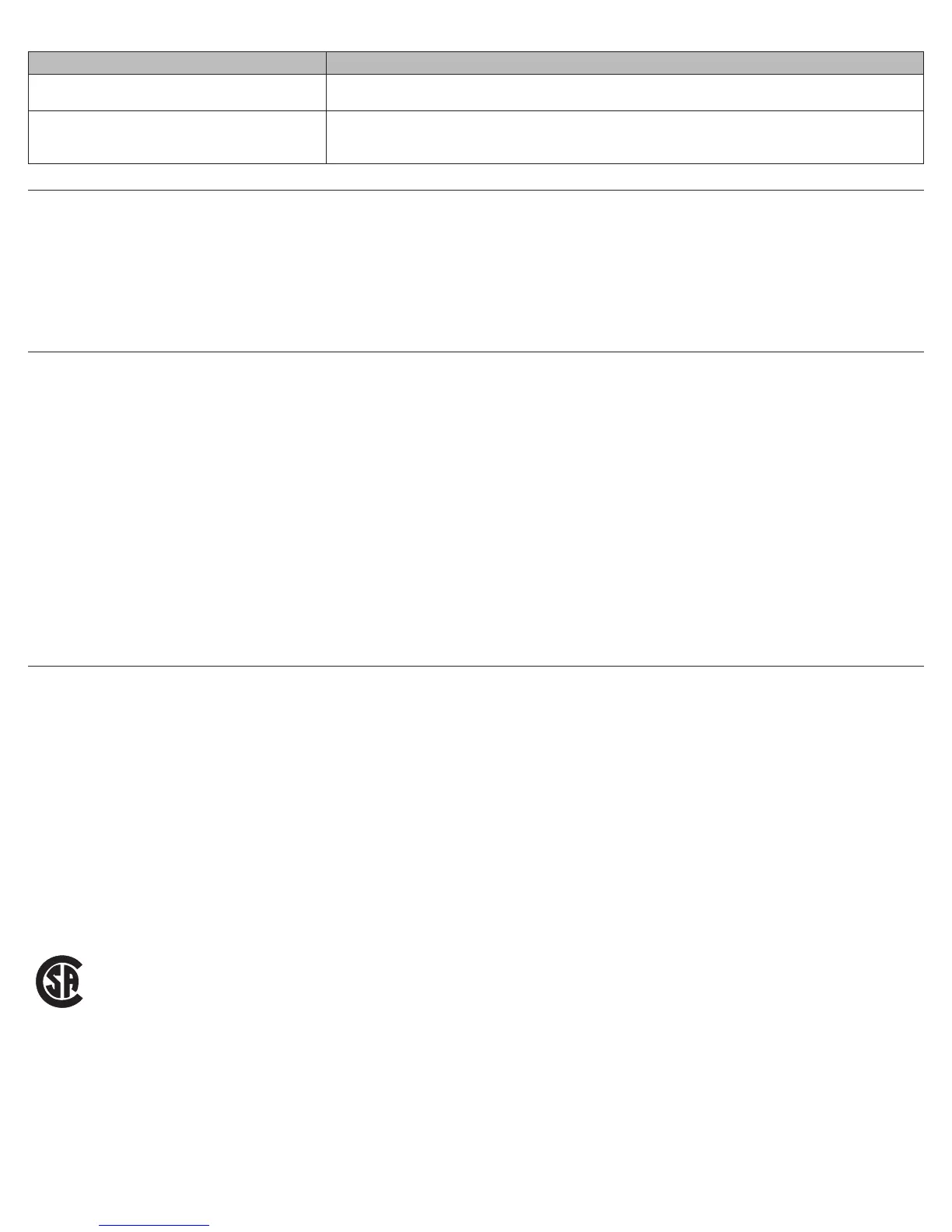

PROBLEM SOLUTION

Hissing sound from iFill oxygen cylinder 1. Turn rotary selector OFF.

2. If hissing sound continues, call your DeVilbiss provider.

iFill oxygen cylinder is on but oxygen is not being

delivered.

1. Rellcylinder.

2. Check that cannula tubing is straight and not pinched. If damaged, replace.

3. Call your DeVilbiss provider for service.

TYPICAL QUESTIONS AND ANSWERS

Q. Why does my iFill make a “pop” sound when I remove the cylinder?

A. The “pop” sound is pressure being released from the system to make the next cylinder easier to install.

Q. Why is the coupler only to be cleaned with a clean, dry, lint-free cloth and only when necessary?

A. Cleaningsolutionsmaybeammableand/ormaycontaminatethecylinder.

Q. Why can’t I use my old cylinders with the iFill?

A. The iFill has a proprietary connection as required by the Food and Drug Administration (FDA) and, therefore, other cylinders are not compatible.

CLEANING/MAINTENANCE

DeVilbiss iFill Personal Oxygen Station Filter

CAUTION – Do not operate the personal oxygen station without the lters installed.

NOTE– The DeVilbiss iFill Personal Oxygen Station has two (2) lters, one on each side of the cabinet (FIGURE A).

NOTE– Perform this procedure at least ONCE A WEEK.

1. Unplug the personal oxygen station from the wall outlet.

2. Removethelters.

3. Cleanthelterswithavacuumcleanerorwashinwarmsoapywaterandrinsethoroughly.

4. Drytheltersthoroughlybeforereinstallation.

Exterior Cabinet

WARNING

Electric Shock Hazard: Unplug the DeVilbiss iFill Personal Oxygen Station when cleaning. Do not remove the oxygen station cabinet. The cabinet should only be

removedbyaqualiedDeVilbisstechnician.Donotapplyliquiddirectlytothecabinetnorutilizeanypetroleum-basedsolventsorcleaningagents.

1. Clean the exterior cabinet by using a damp cloth or sponge with a mild house hold cleaner and wipe it dry.

2. Only if necessary, wipe the coupler with a clean, dry, lint-free cloth.

SPECIFICATI ONS

DeVilbiss iFill Personal Oxygen Station

Operating Temperature:.......................................................................................................................................................................................................... 41º to 95ºF (5º to 35ºC)

Operating Humidity Range: ....................................................................................................................................................................................... 15 to 95% R.H. non-condensing

Operating Altitude: ................................................................................................................................................................................................0 to 6,562 Feet (0 to 2,000 Meters)

Storage Temperature Range: .................................................................................................................................................................................. -40ºF to +140ºF (-40ºC to +60ºC)

Storage Humidity Range: .................................................................................................................................................................................................. 10 to 95% non-condensing

Electrical Rating: .................................................................................................................................................................................................................... 115V~, 60Hz, 4.1 Amps

Operating Voltage Range: .........................................................................................................................................................................................................187 – 264V~ 50/60Hz

Power Range: .................................................................................................................................................................................................................................400 Watts Average

Oxygen Purity: ....................................................................................................................................................................................................................................... 93% O2 ± 3%

Dimensions: (including casters) w/o cylinder ..................................................................................................................12.25”W x 28.5”H x 22.5”D (31.1 cm x 72.4 cm x 57.4 cm)

Weight: ..................................................................................................................................................................................................................................................66 lbs. (30 kg)

Shipping Weight: ................................................................................................................................................................................................................................76 lbs. (34.5 kg)

This unit is classified as nonprotected per EN60601-1 .....................................................................................................................................................(Ordinary Equipment) IPX0

Approvals UL60601-1 & CAN/CSA C22.2 No. 601.1-M90 ....................................................................................................................................................................................CSA

®

156855

iFill Oxygen Cylinder Typical Fill Times

NOTE– All lling times are approximate and may vary depending on altitude and environmental conditions.

Typicalcylinderlltimefromemptyto2,000±200psig(138±13.8bar)areasfollows:

M4 (0.7L) .................60 Minutes C (1.8L) .............130 Minutes

M6 (1.0L) .................75 Minutes D (2.9L) .............215 Minutes

ML6 (1.2L) ...............90 Minutes E (4.7L) .............350 Minutes

NOTE- Degradation of performance may occur if unit is operated outside of specied operating parameters.

Loading...

Loading...