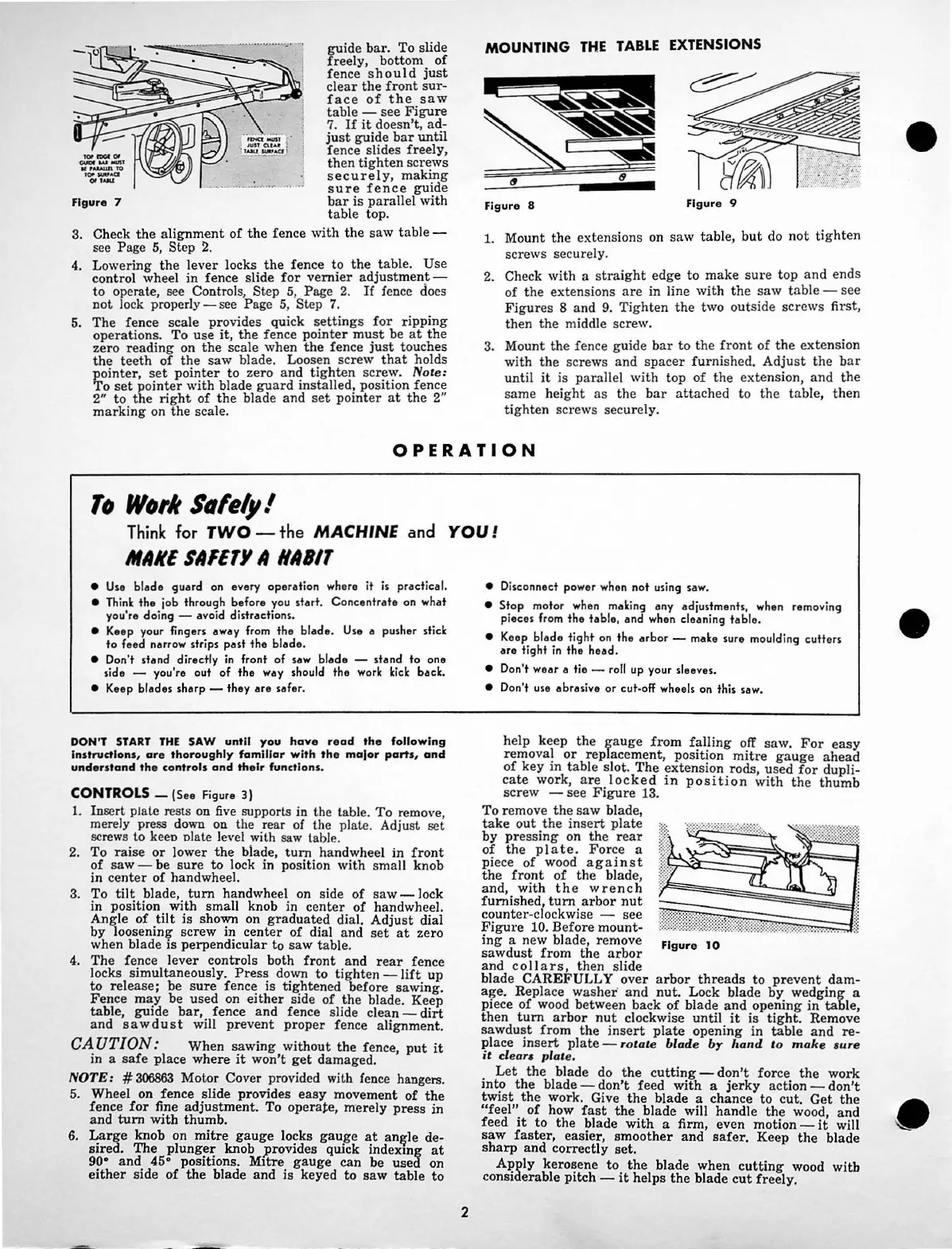

Figure 7

guide

bar.

To slide

freely, bottom

of

fence

sho

uld

just

clear

the

front

sur-

f

ace

of

the

saw

table

- see

Figure

7.

If

it

doesn't,

ad-

just

guide

bar

until

fence slides freely,

then

tighten

screws

securely,

making

sure

fence

guide

bar

is

parallel

with

table

top.

3. Check

the

alignment

of

the

fence

with

the

saw

table -

see Page

5,

Step

2.

4. Lowering

the

lever

locks_

the

fence t_o

the

_table.

Use

control wheel

in

fence

shde

for

vernier

ad1ustmen~ -

to

operate, see Controls, Step 5, Page

2.

If

fence does

not

lock properly - see Page 5,

St

ep

7.

5.

The

fence scale provides quick

settings

for

ripping

op

erations

. To

use

it,

the

fence

pointer

mu.st be

at

the

zero

reading

on

the

scale

when

the

fence Ju

st

touches

th

e

teeth

of

the

saw

blade. Loosen screw

that

holds

pointer

,

set

poll!ter

to

zero an~

tighten

scr~'Y·

Note:

To

set

pointer

with

blade gua

rd

mstalled, pos1t1on fence

2"

to

the

right

of

the

blade and

set

pointer

at

the

2"

marking

on

the

scale.

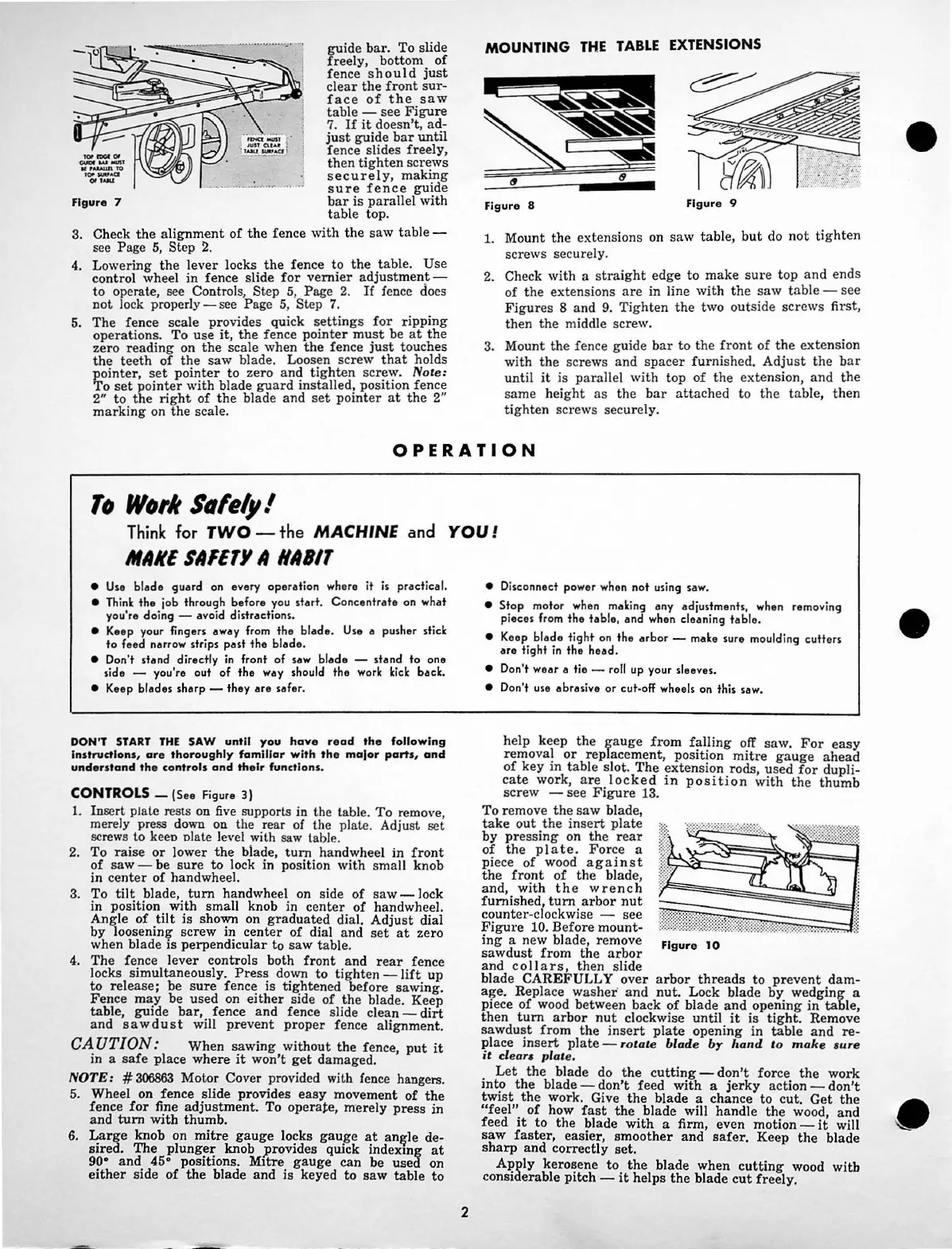

MOUNTING

THE

TABLE

EXTENSIONS

Figure 8

Figure 9

1.

Mount

the

extensions on

saw

table,

but

do not

tighten

screws securely.

2.

Check with a

straig

ht

edg

e

to

ma

ke

sure

top

and

ends

of

the

extensions

are

in

line

with

the

saw

tabl

e - see

Figures

8 and 9.

Tighten

the

two outside screws first,

then

the

middle screw.

3. Mount

the

fence guide

bar

to

the

front

of

the extension

with

the

screws and

spacer

furnished. Adju

st

the

bar

until

it

is parallel

with

top

of

the

extension,

and

th

e

sa

me

height

as

the

bar

attach

ed to

the

table,

then

tighten

scr

ews securely.

OPERATION

To

Worlt

Solely!

Think

for

TWO

- the

MACHINE

and

YOU

I

MANE

SAFETY

A

HABIT

• Use

blade

guard

on

eve

ry

operation

wh

ere

it

is practical.

• Think

the

job through

before

you

star

t.

Conc

e

ntrate

on

what

you

're

do

ing - avoid distractions.

• Keep your fingers away from

the

blade

. Use a pusher stick

to

feed narrow strips

past

the

blade

.

• Don't

stand

directly in

front

of

saw

blade

-

stand

to

one

side - you're

out

of

the

way should

the

work

kick

back.

• Keep blades sharp -

they

are

safer.

DON'T

START

THE

SAW

until

you

have

read

the

following

Instructions,

are

thoroughly

famlllar

with

the

ma)or

parts,

and

understand

the

controls

and

their

functions.

CONTROLS

- (S

ee

Figure

3)

1.

In

se

rt

plate rests on five supporl.s

in

the table.

To

remove,

merely press down on the rear of the plate. Adjust set

screws

to

keen olate level with

saw

table.

2. To

raise

or

lower

th

e blade,

turn

handwheel

in

front

of saw - be

sure

to

lock

in

position

with

sma

ll knob

in

cent

er

of

handwheel.

3. To

tilt

bl

ade,

turn

hand

wheel on side

of

saw

- lock

in position with small knob

in

center

of

handwheel.

Angle

of

tilt

is shown on

graduated

dial.

Adjust

dial

by

loose

ning

screw in ce

nt

er of dial and

set

at

zero

when blade

is

perpendicular to s

aw

table.

4.

The

fence l

ever

controls both

front

and

rear

fence

locks simultaneously.

Press

down

to

tight

en -

lift

up

to

release; be

sure

fence

is

tightened befo

re

sawing.

Fence

may

be

used on

either

side

of

the

bl

ade. Keep

tab

le, guide

bar,

fence

and

fence slide cl

ean

-

dirt

and

sawd

ust

will

prevent

proper

fence alignment.

CA

UT/ON:

When

sawing

without the fence,

put

it

in

a

safe

place

where

it

won't

get

damaged.

NOTE

: #

306863

Motor Cover provided with fence hangers.

5. Wheel on fence slide provides

easy

movement

of

the

fence

for

fine

adjustment

. To operate, m

ere

ly

press

in

an

d

turn

with thumb.

6.

Larg

e knob on

mitre

gauge

locks

gauge

at

an~le de-

sired.

The

plunger

knob

provides

quick indexing

at

90•

and

45• positions.

Mitre

gauge

can

be u

se

d on

either

side

of

the

blade and is keyed

to

sa

w table to

2

• Disconnect power when

not

using saw.

•

Stop

motor when making any adjustments, when removing

pi

eces

from

the

table,

an

d when cleaning

tabl

e.

• Keep

blade

tight

on

the

arbor

- make sure moulding

cutters

are

tight

in

the

head.

• Don't weor a tie - roll up your sleeves.

• Don't use

abras

ive

or

cut-off wheels on this saw.

help

ke

ep

the

gauge

from

falling

off saw.

For

easy

remova!

or

replacement, posit\on

mitre

gauge

ahe

ad

of

key

m

tabl

e slot.

The

extension rods, u

sed

for

dupli-

cate

work,

are

lo

cke

d

in

position

with

th

e

thumb

screw - see

Figure

13.

To remove

the

saw

blade,

take

o

ut

th

e in

sert

plate

by

pressing

on

the

rear

of

the

plate.

Force

a

piece

of

wood

against

the

front

of

the

blade,

and,

with

the

wrench

furnished,

turn

arbor

nut

---

!i_

:

counter-clockwise - see

F

igur

e 10. Before mount-

ing

a new blade, remove

Figure

10

sawdust

from

th

e

arbor

and

co

lla

rs,

then

slide

blade CAREFULLY

over

arbor

threads

to

pr

e

vent

dam-

age

. Replace

washer

· a

nd

nut.

Lo

ck blade

by

wedging

a

piece

of

wood

betw

een back

of

blade

and

opening

in

tabl

e,

then

turn

arbor

nut

clockwise

until

it

is

tight

. Remove

sawdust

from

the

insert

plate

opening

in

tab

le

and

re-

place

insert

plate

-

rotate

blade

b:r

hand

to

make

1

ure

it

clear,

plate.

Let

the

blade do

th

e

cutt

i

ng

-

don't

force

the

work

into

the

blade -

don't

feed

with

a j

erk

y action -

don't

twist

the

work. Give

the

blade a chance

to

cut.

Get

the

"feel"

of

how

fast

the

blade will handle

the

wood,

and

feed

it

to

the

blade

with

a firm, even motion -

it

will

saw

fas

ter, easier,

smoother

and

safer.

Ke

ep

the

blade

sharp

a

nd

correctly

set.

Apply kerosene

to th

e bl

ade

when

cutting

wood witb

considerable pitch -

it

helps

the

blade c

ut

freely.

Loading...

Loading...