OverLord 3D Printer User Manual

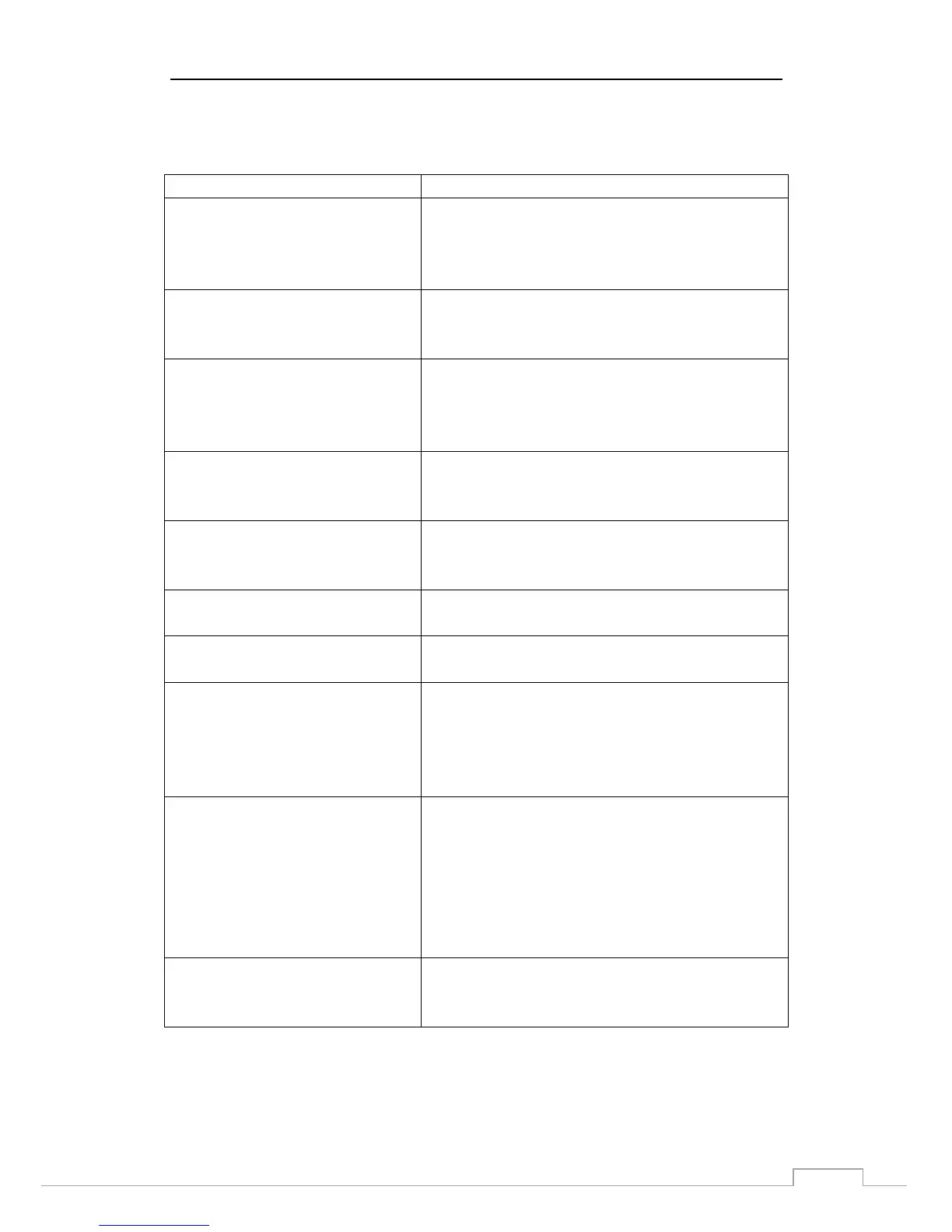

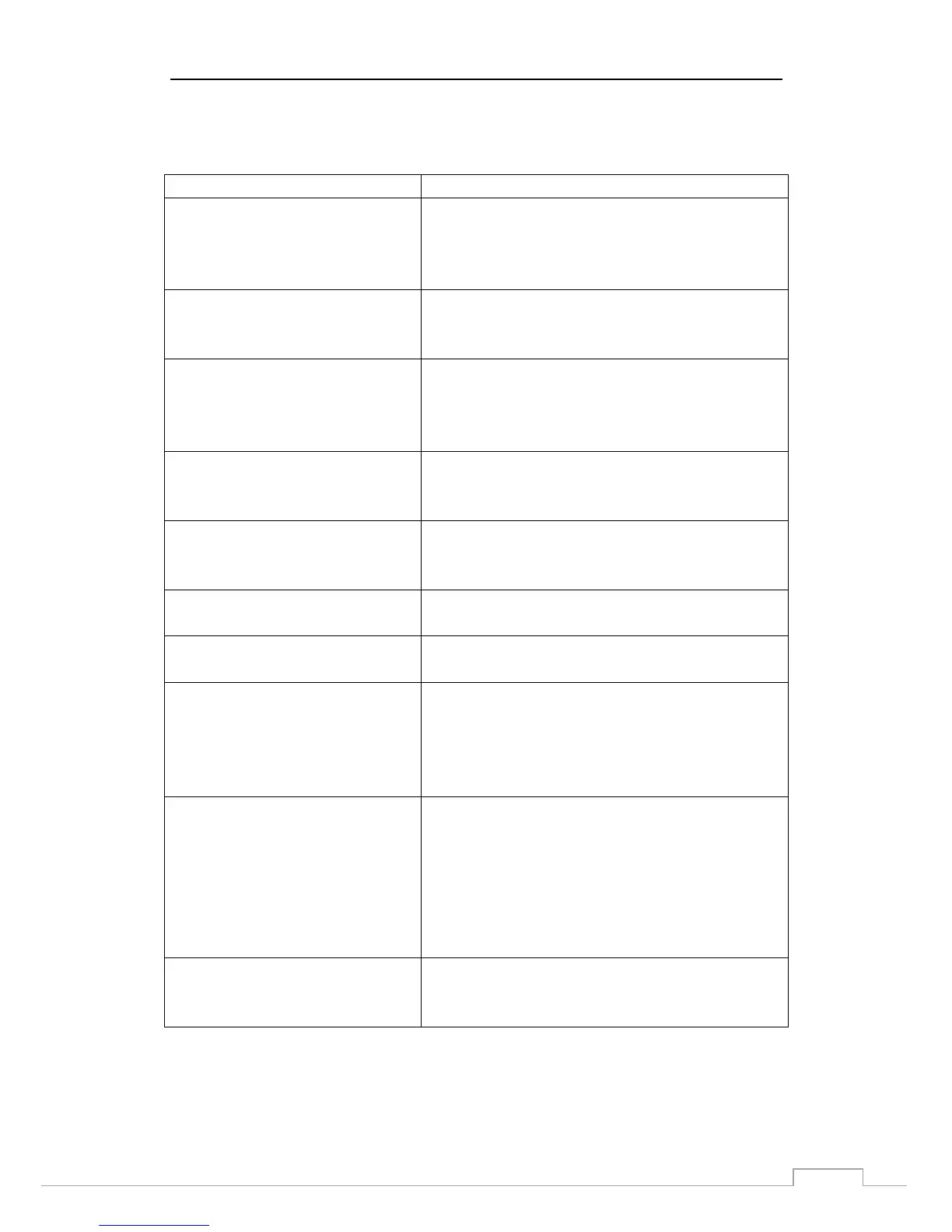

When I installing Cura, antivirus

software stops it.

We promise that the Cura installation file provided in the

OverLord SD Card does not contain any harmful files

that may destroy your computer or files. Please add trust

for Cura installation file.

The progress bar stops for a long time

during nozzle heating.

Poor contact of nozzle heating module. Check its wire

contact and restart 3D printer. Contact

support@dreammaker.cc if it appears frequently.

Print detaches from build plate;

Print bottom edge detaches;

The nozzle hits build plate during first

layer printing;

Run “Level—Auto” in main menu to calibrate and

remember to paint 3 layers of glue on build plate and

wait glue drying before printing.

The nozzle run off the original

trajectory during printing;

There is deviation between layers.

Add a little lubricating oil to the 6 rods of OverLord.

Check the tension in the 3 belts.

Follow the steps in “3.4 Fasten the belt”.

Poor contact of temperature sensor in nozzle. Check its

wire contact and restart 3D printer. Contact

support@dreammaker.cc if it appears frequently.

Poor contact of temperature sensor on build plate, please

contact support@dreammaker.cc.

Broken or poor contact of temperature sensor in nozzle,

please contact support@dreammaker.cc.

How to reduce connecting strands?

Try larger retraction length and speed in

“Setting—Retraction setting”. Lower nozzle temperature

to 210~220℃ during printing and set printing speed to

80~110mm/s. Get rid of connecting strands and refine

the model by sandpaper or heating method.

Not enough material coming out of

nozzle during printing;

Abnormal porous structure on print

surface;

Nozzle seems blocked.

Confirm the setting in Cura is correct;

Check whether extruder is extruding material properly.

If it is not, select “Material” and reload filament once

more to see is there any material coming out of nozzle

after loading.

If the material doesn’t come out of nozzle, follow the

steps in “3.1 clean the nozzle”.

Filament is broken inside machine;

The function of “Material” (auto

reject/feed filament) doesn’t work.

Follow the steps in “3.2 Clean the broken filament inside

extruder” or “3.3 Clean the broken filament inside

filament feeding tube”

Loading...

Loading...