25

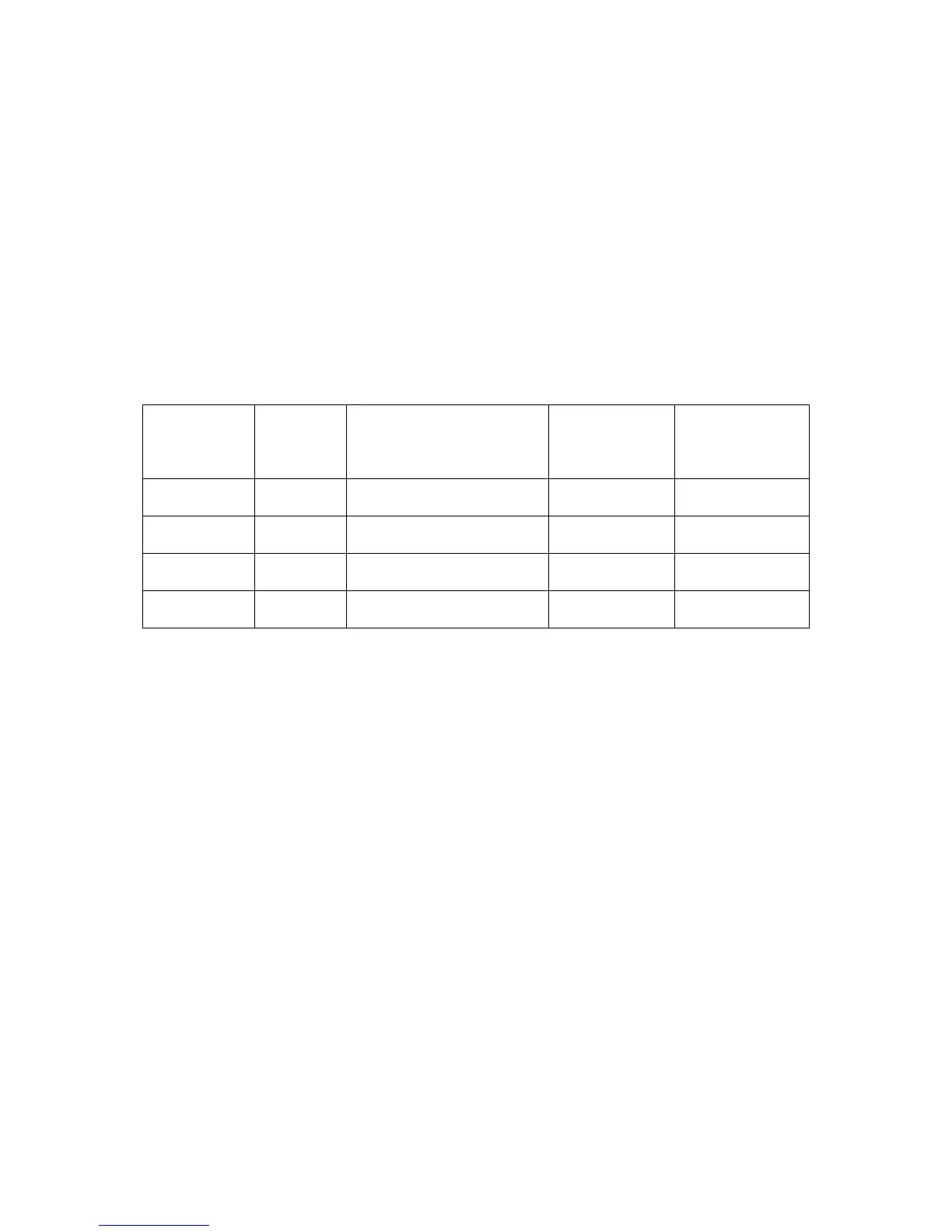

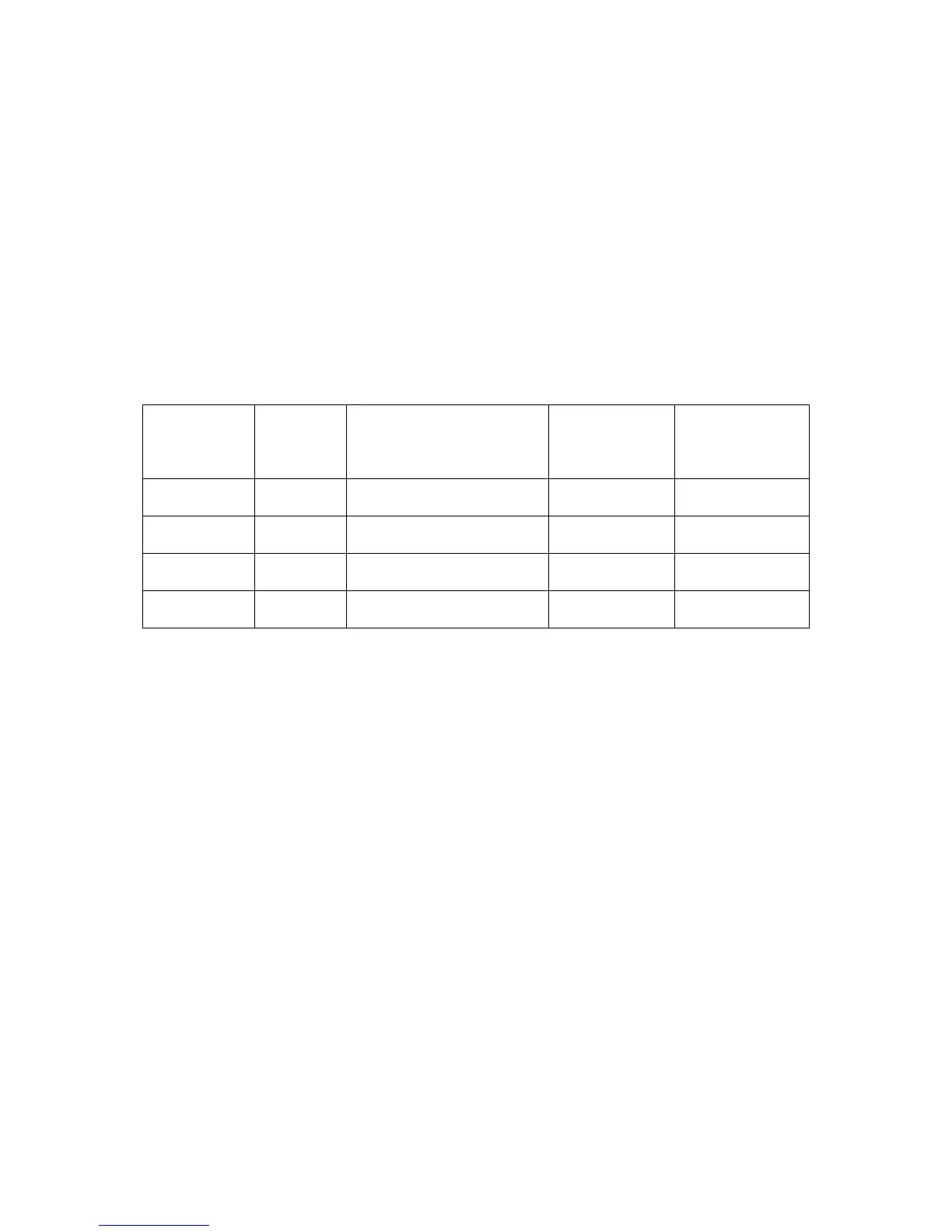

Table 2 – Tensioner Air Pressures

Table 2 – Tensioner Air Pressures

Wire

Diameter

Tensioner Air Pressure Wire Tension

(lbs)

Wire Tension

(N)

0.006” 0.150mm 10 psi 69 Kpa 2.1 lb 9.4 N

0.008” 0.200mm 15 psi 103 Kpa 3.1 lb 13.8 N

0.010” 0.250mm 20 psi 138 Kpa 4.2 lb 18.1 N

0.012” 0.300mm 25 psi 173 Kpa 5.2 lb 23.2 N

Pulleys

The pulleys wear out as the abrasive diamond wire cuts the pulley groove wider and deeper. There

are two types of pulley wear indicative of mechanical problems:

1. Eccentric wear results if a pulley does not rotate freely. The diamond wire cuts one portion of

the pulley groove deeper than another if the pulley sticks during part of its rotation. You

observe eccentric wear as an up and down motion of the wire when viewed from the side.

2. Flange wear results from misalignment between pulleys or misalignment between a pulley and

the capstan. The wire must always go into the pulley groove parallel to the sides of the pulley.

Flange wear appears as side-to-side flutter of the wire when viewed on edge. Misalignment

quickly erodes the pulley flange, and the wire could jump off the pulley.

If you run the wire drive unloaded and at high speed, you might notice wire vibration between the

pulleys. This type of vibration dampens out when the wire contacts the specimen.

Pulleys will eventually reach the end of their useful life even if the saw geometry is accurate. The

life of a pulley depends to some extent on the wire tension and the material you are cutting.

Loading...

Loading...