26

To replace a pulley:

1. Remove the jam nut using a 9/16” socket or wrench.

2. Use a two-legged wheel puller to pull the old pulley/bearing assembly forward and off the

shaft.

3. Clean the shaft and check that it is smooth. If it has any significant scratches, carefully work

them out with an abrasive pad or emery cloth.

4. Apply a thin layer of petroleum jelly to the shaft.

5. Slide the new pulley assembly onto the shaft. Gently tap with a soft mallet if necessary. DO

NOT HAMMER.

6. Replace the nut and tighten until there is no endplay, but not so tight as to bind the bearing.

After replacing a pulley, verify that it spins freely and does not wobble.

Preventative Maintenance

Daily

Inspect the tensioner pulleys for wear or damage.

Inspect the pulleys for wear or damage.

Perform a general inspection of entire machine, looking for

missing or worn hardware, replace as necessary.

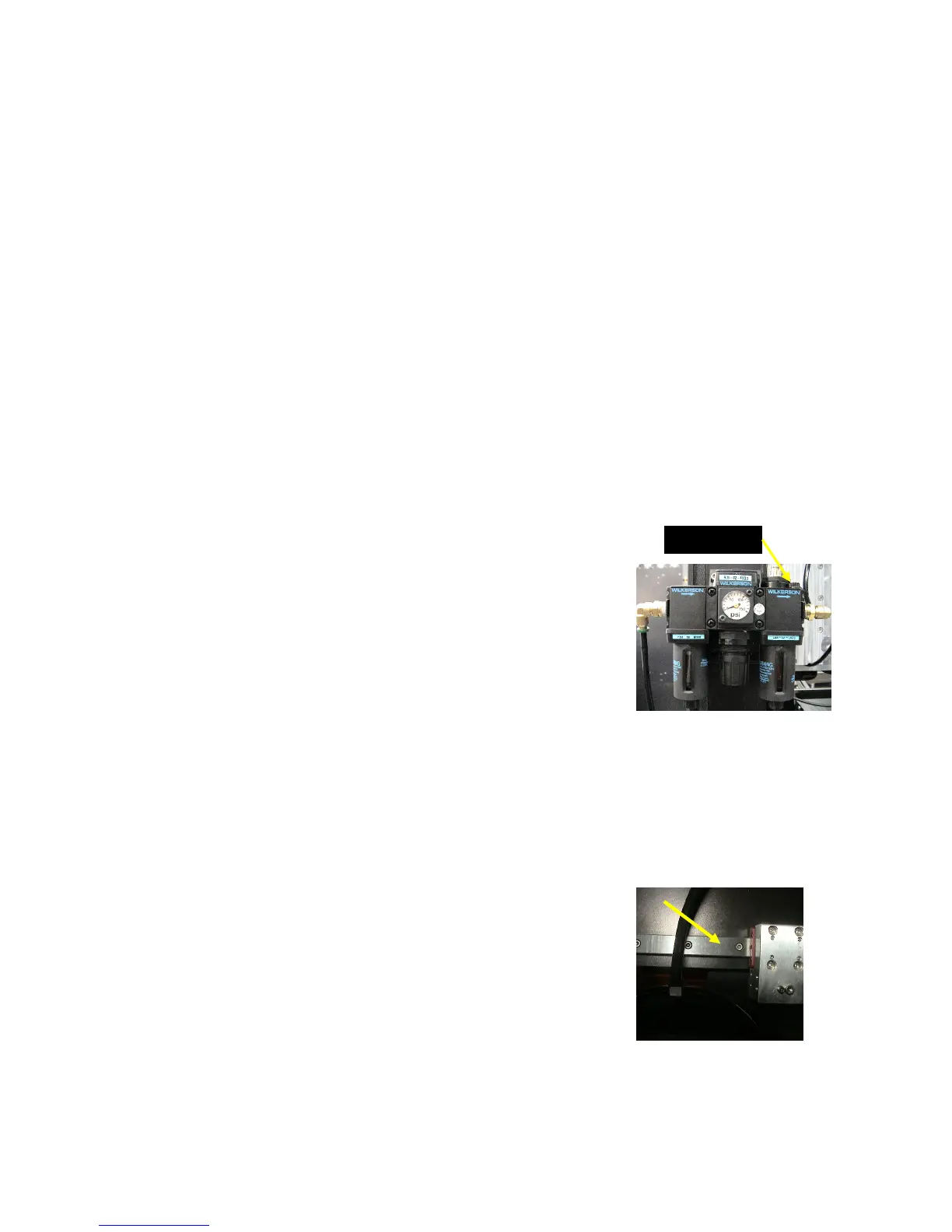

Inspect and fill the oil reservoir as necessary (CT400, CT800

only). Use Dixon Lubricant 8TL016 (Non-Hydraulic Oil) Or

equivalent.

Weekly

Turn the grease cup on the front end of the capstan shaft, one turn after every 40 hours of

use. Mobilith SHC 100— Lithium based synthetic grease.

Monthly

Inspect the yoke side rails and bearings Clean and lubricate

as necessary.

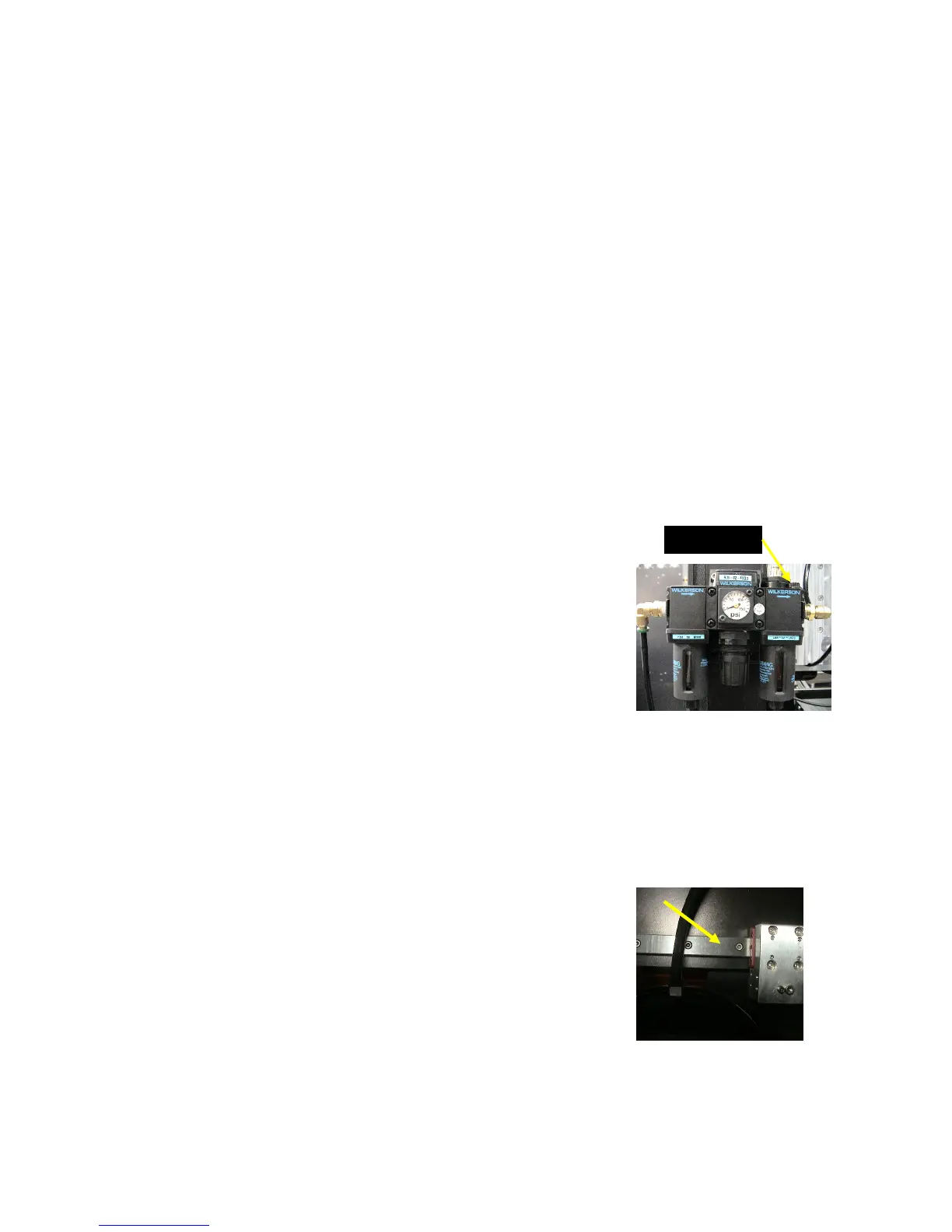

Grease the two-pin driver

Disconnect the capstan motor cable connector.

Remove the four 3/16” flat head screws holding the

motor and the adapter plate to the end support.

Pull straight out on the motor, removing the motor, guard, and two-pin driver as one

assembly.

Loading...

Loading...